TRANSMISSION AND TORQUE CONVERTER CD3340B/YB4411

7-44

Published 04/07/2015 Control # 569-00

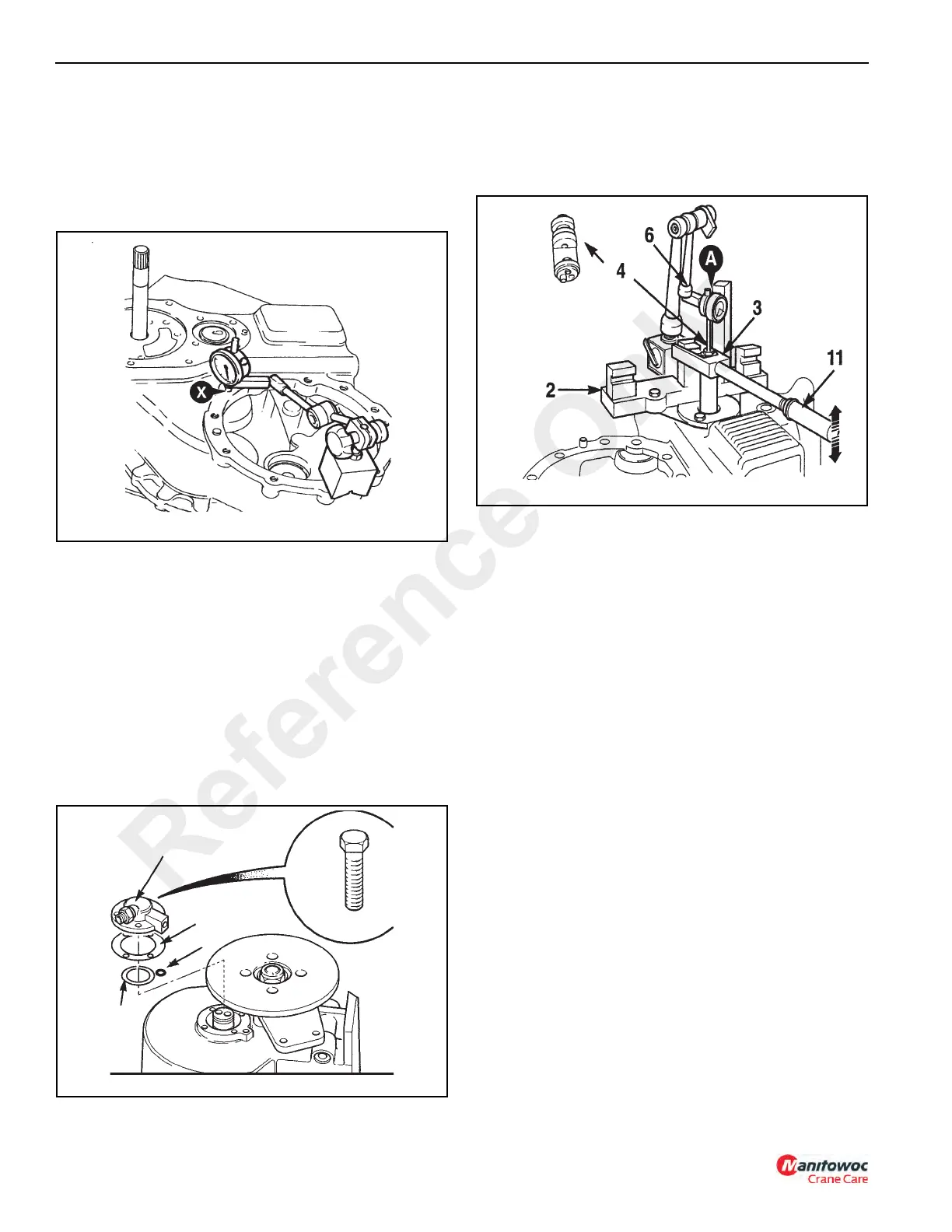

NOTE: Access to the layshaft end face is gained through

the 4WD bolt hole X, as shown in Figure 7-53.

Calculate the required thickness of shims to give

correct end play, which should be 0.03 - 0.08 mm

(0.001 - 0.003 in). The end shaft play should be set

as near as possible to the minimum tolerance.

23. Remove the layshaft end cap (27, Figure 7-54). Coat the

layshaft outer bearing with a Lithium Base, E.P. No. 2

bearing grease and add or subtract shims 29 to give

correct end play (install shims between the outer race of

bearing and layshaft end cap).

Ensure the gasket is used when calculating the shim

thickness.

24. Install new O-ring (30) in end cap (27). Coat the O-ring

with grease to hold in position.

25. Install the layshaft end cap (27) with new gasket (28).

Apply Loctite 243 to bolts (26) and tighten to a torque of

56 Nm (42 lb-ft).

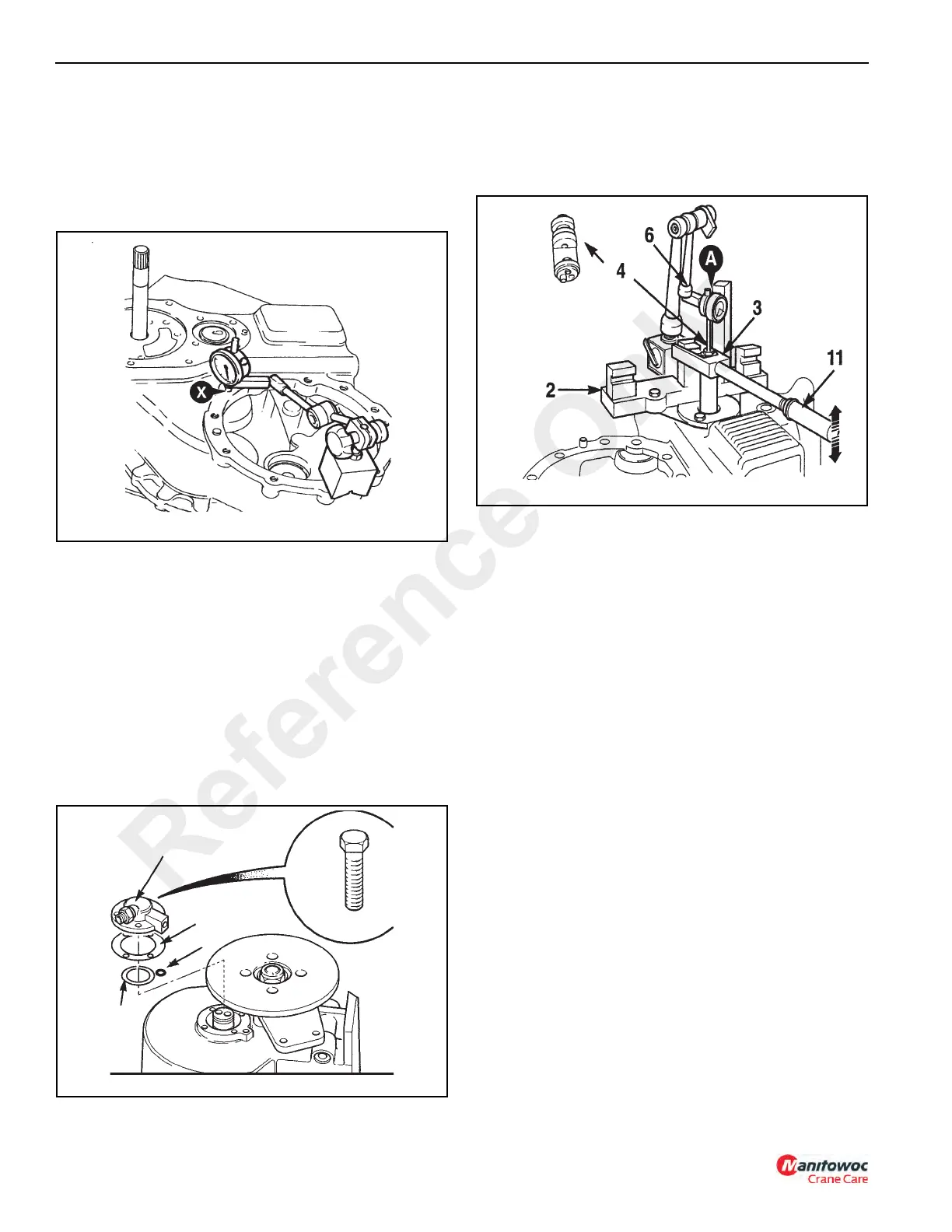

26. Measure the end play of the main shaft using the end

play checking kit (see Figure 7-21)

NOTE: Numbers in Figure 7-55 correspond with numbers

in Figure 7-22.

a. Install adapter 4 into tapped hole in the main shaft

securing it with an M10 x 20 bolt.

b. Mount base plate 2 onto the transmission and locate

yoke 3 and wrench 11 into adapter 4 and pillar 6. Set

the wrench to 35 Nm (26 lb-ft).

c. Using a magnetic block, mount the dial test indicator

(DTI) A with the probe on the head of adapter 4 and

adjust to read zero.

d. While rotating the main shaft back and forth seat the

bearings, lift and depress wrench 11 and note the

reading on the DTI.

NOTE: To rotate the main shaft, use an air line and adapter

tool (Figure 7-19) and rotate the output flange.

e. Remove wrench 11, adapter 4, and end play setting

tool from the main shaft assembly.

f. Add or subtract shims to correct the end play. (The

end play should be set as close as possible to the

minimum tolerance.) The shims must only be

installed between the bearing outer race and

spacer. When the correct end play has been

established - INSTALL SPACER 50 WITH NEW O-

RINGS 51 (Figure 7-57)

g. Repeat steps 9A - 9E to recheck end play on the

input shaft.

h. Remove bolt A (see step 12) from the forward shaft

and install plug (50, Figure 7-56) using new O-rings

51.

Reference Only

Loading...

Loading...