GROVE 7-45

CD3340B/YB4411 TRANSMISSION AND TORQUE CONVERTER

Published 04/07/2015 Control # 569-00

27. If the end play checking kit is not available, use the

following procedure.

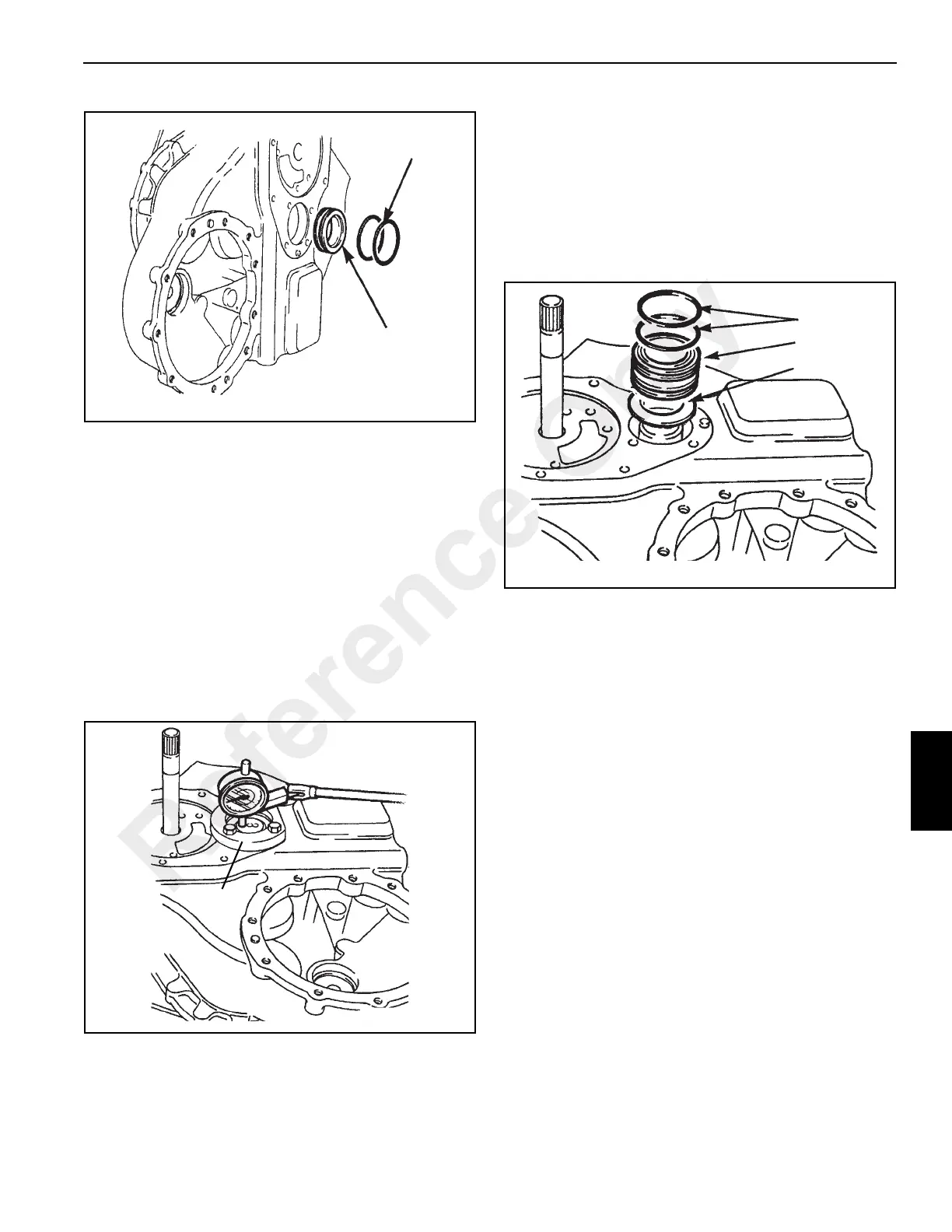

a. Install end play tool B (P/N 1900449) over the main

shaft end bearing and spacer (Figure 7-57). Tighten

the bolts.

b. Screw a suitable bolt into the tapped hole in the end

of main shaft and using a suitable lever under the

bolt, move the main shaft back and forth when

measuring the end play.

c. Set up a dial test indicator as shown in Figure 7-57.

Measure the main shaft end play, which should be

0.03 - 0.08 mm (0.001 - 0.003 in). Rotate the main

shaft (use the brake disc) while measuring in order

to seat the bearing fully.

NOTE: To rotate the main shaft, use air and adapter tool P/

N 1902746 (see Figure 7-19)

d. Add or subtract shims (34, Figure 7-58) to correct

the end play. (The end play should be set as near as

possible to the minimum tolerance.) The shims must

only be fitted between the bearing outer race and

spacer (50). When the correct end play has been

established - Install spacer (50) with new O-rings

(51).

28. If the pump flow/pressure was below normal, coat the

machined surface of the pump with engineers’ blue and

insert into the pump housing. Rock the pump several

times and remove. Check the machine faces for contact.

Remove high spots as necessary until full face contact is

made. Thoroughly clean all surfaces with a suitable

solvent and dry before installing.

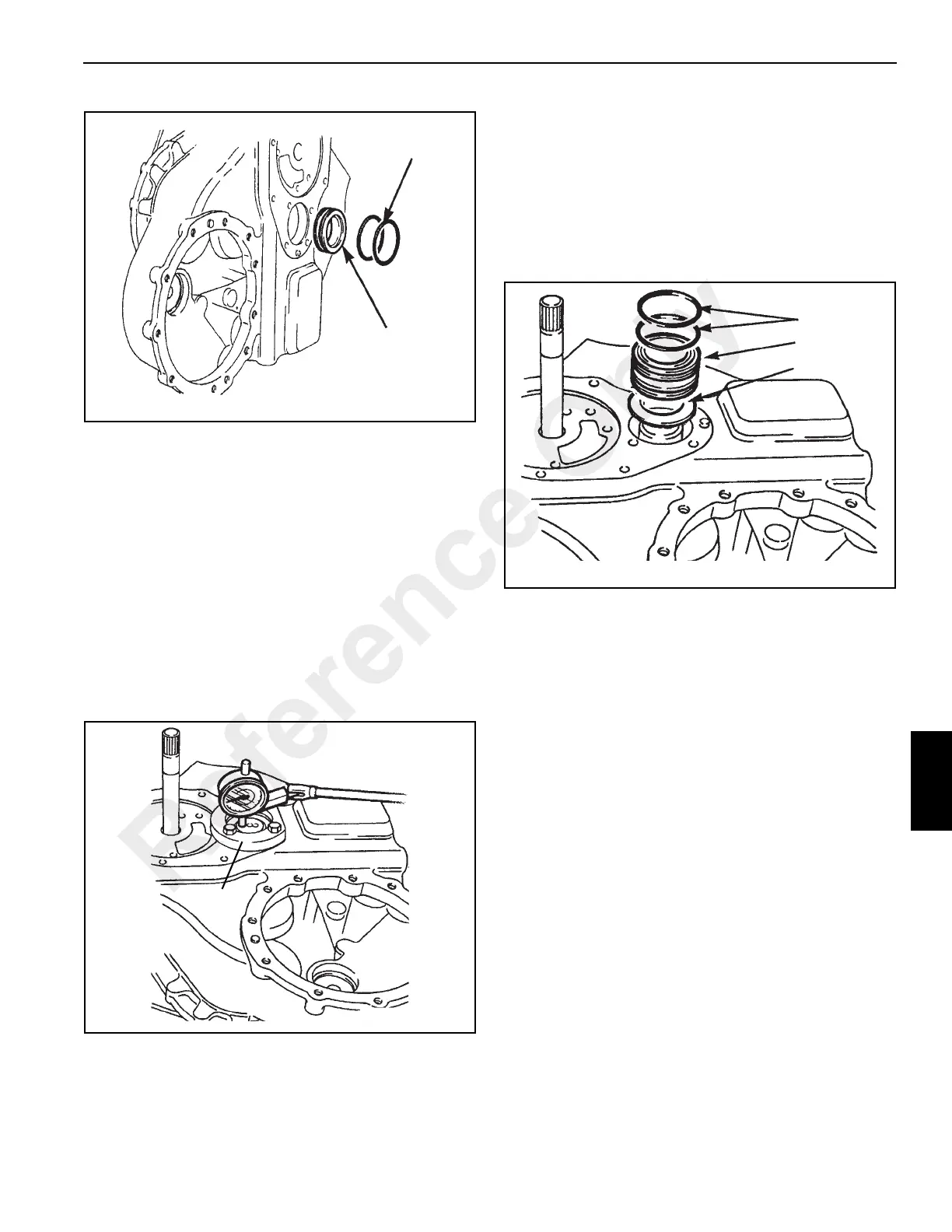

Make sure all bearings have been lubricated with

Lithium Base, E.P. No. 2 bearing grease. Apply Loctite

574 to mating face of flywheel housing. Install the

flywheel housing, locating it on dowels (37, Figure 7-59).

Apply Loctite 243 to bolts (35) and tighten to a torque of

56 Nm (42 lb-ft).

Reference Only

Loading...

Loading...