AXLES/DRIVE SHAFTS/WHEELS AND TIRES CD3340B/YB4411

8-22

Published 04/07/2015 Control # 569-00

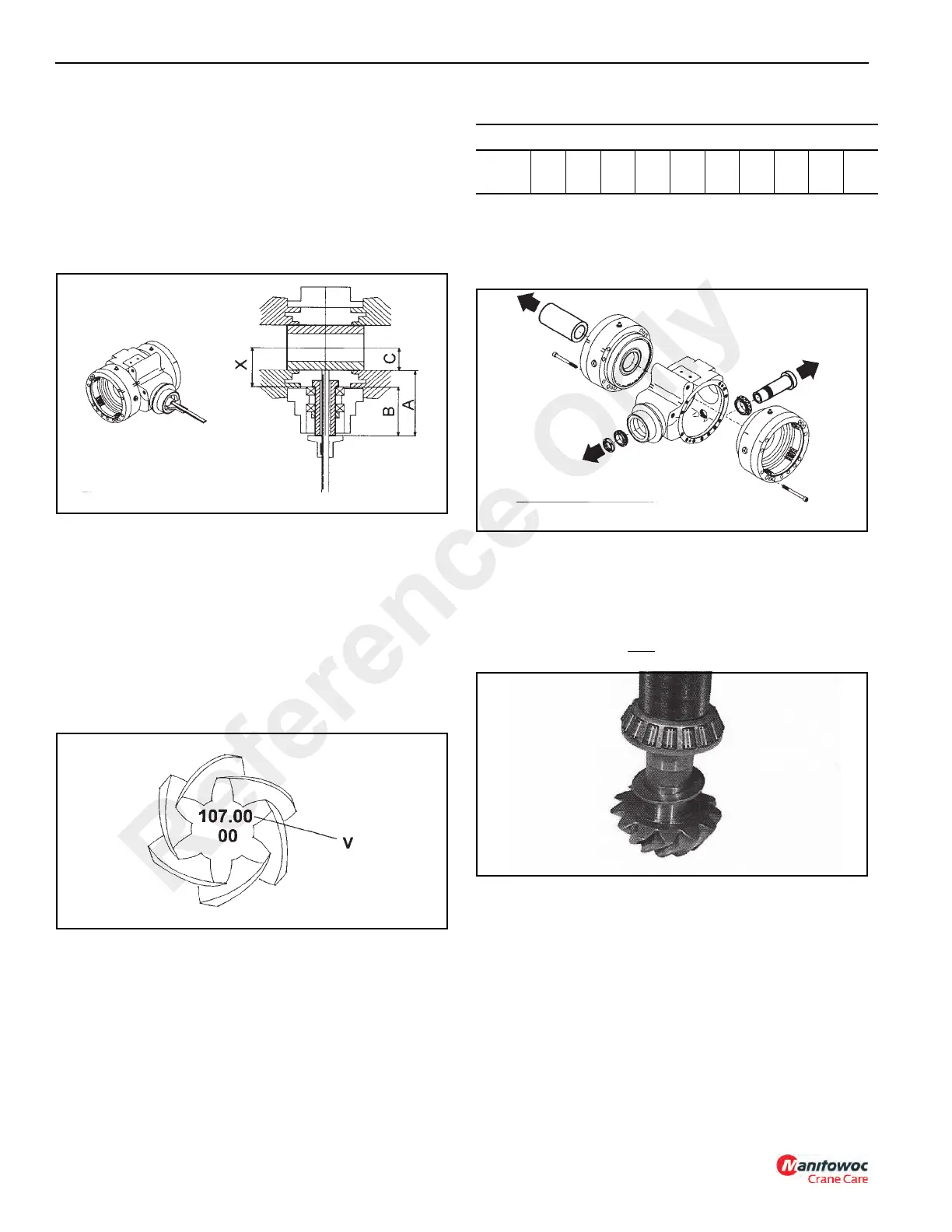

5. Measure the distance measurements described below

using a depth gauge through the hole in the false pinion

(Figure 8-85).

X = (conical distance to be measured)

A = (measured value)

B = (known value - 100 mm)

C = (known value - 45 mm)

Measured values all millimeters.

6. To determine the amount of shims (S) required between

the pinion and bearing perform the following calculation:

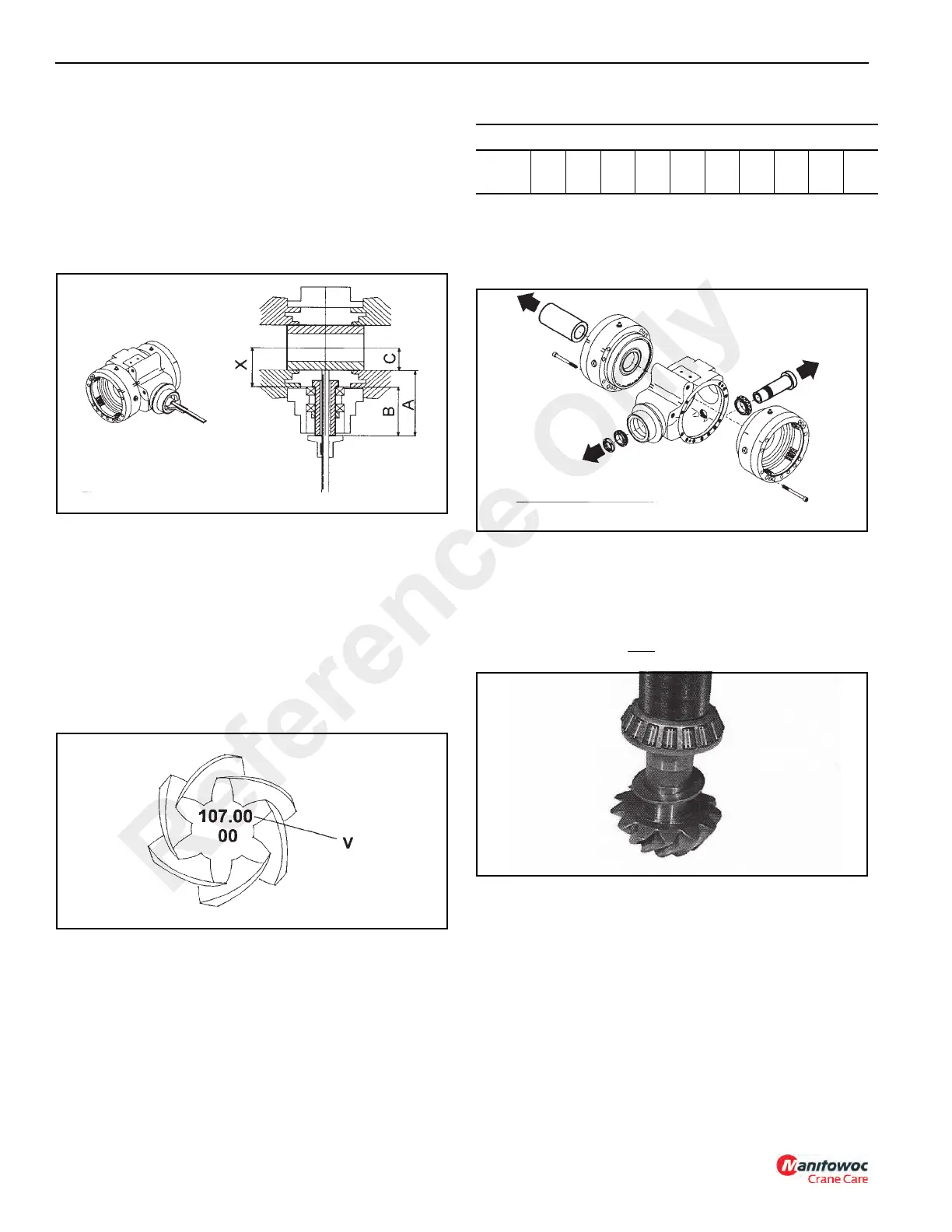

a. Subtract the (V - requested conical distance) value

stamped on the pinion head (Figure 8-86) from the

measured (X) value.

S=X-V

b. (X) value is found by adding measurements (A and

C) together and subtracting B.

X=(A+C)-B

7. Choose the suitable shim from the available shims in

Table 6-1. Shims may be found in the parts manual

supplied with the crane.

Table 8-2.

8. Remove the false pinion, the bearings and the ring nut

from the center housing (Figure 8-87). Remove the false

differential box from the center housing. Remove the two

brake flanges from the center housing.

9. Insert the shims (S) chosen in step 7 on the pinion shaft

with the chamfer edge against the gear (Figure 8-88).

Using SPECIAL TOOL P/N 1901772 press the bearing

onto the pinion shaft. Be sure it is fully set. Install the

washers and new elastic spacer onto the shaft.

NOTE: Always use a new

elastic spacer.

10. Insert the bevel pinion assembly into the center housing

and the second bearing cone onto the pinion end

(Figure 8-89).

In order to properly install the bearing use SPECIAL

TOOL P/N 1901772 and a hammer to drive the bearing

into position. Hold a sledge hammer against the gear

while driving the bearing.

S = SHIM RANGE

Thick

(MM)

2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4

Reference Only

Loading...

Loading...