GROVE 8-23

CD3340B/YB4411 AXLES/DRIVE SHAFTS/WHEELS AND TIRES

Published 04/07/2015 Control # 569-00

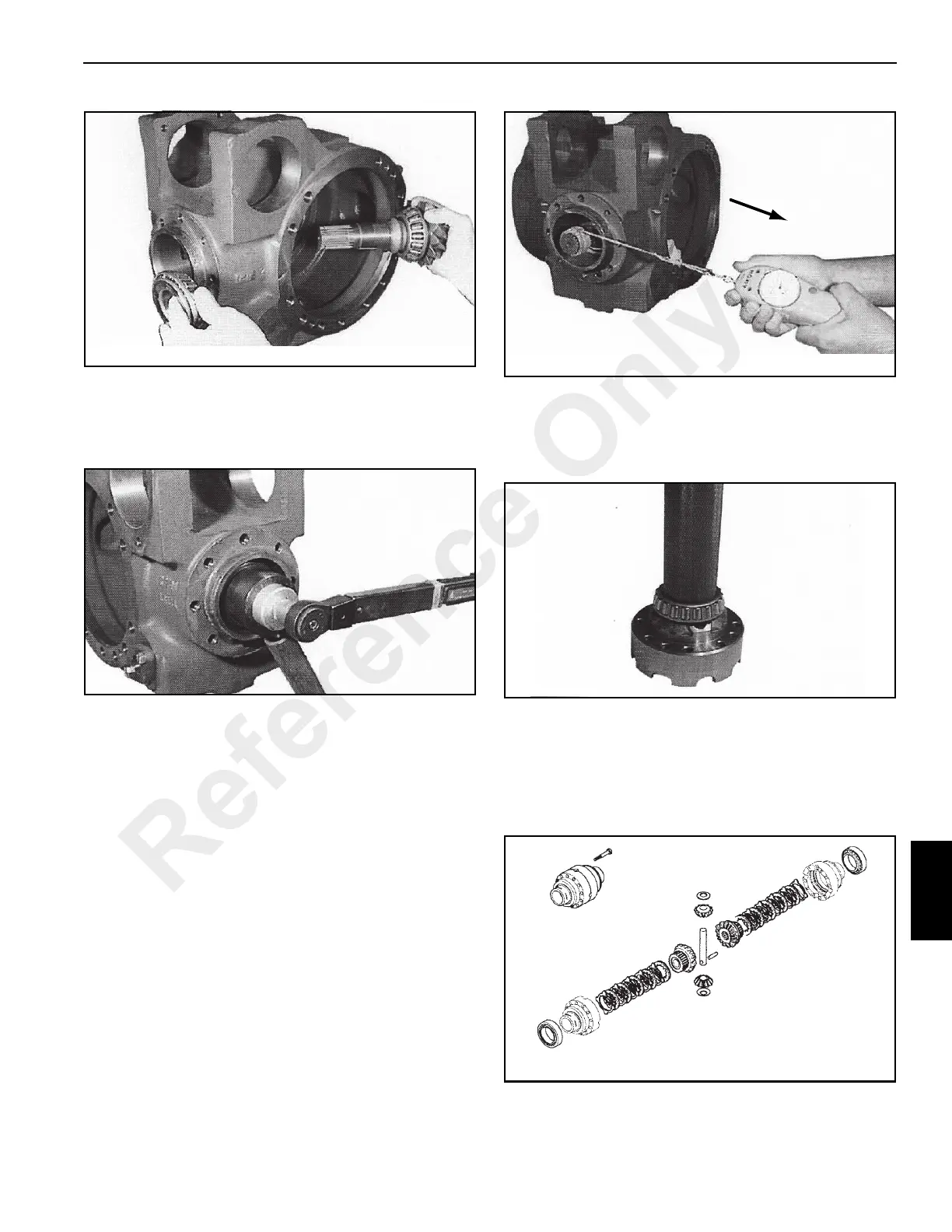

11. Assemble onto the pinion shaft a new ring nut washer

and ring nut retainer.

Screw the ring nut in, using SPECIAL TOOLS P/N

1901768 and P/N 1901773 (Figure 8-90).

NOTE: The torque setting is determined by the pre-loading

measurement on the bearings. Tighten the ring nut

step by step. If it is tightened too much, the elastic

spacer should be replaced and the procedure

repeated. When checking the pre-load, it is

advisable to hit the pinion ends slightly with a soft

hammer to set the bearings.

12. To check the bearing pre-load, use a dynamiter and

string. Wind the string around the spline end of

SPECIAL TOOL (P/N 1901772) inserted on the pinion

shaft (Figure 8-91).

NOTE: The pre-load measurement should be done without

the seal ring installed.

With the dynamiter attached to the string, pull the

dynamiter and take a reading. Tighten or loosen the ring

nut until 9.2 - 13.8 daN (20 - 31 pounds) of force is

required to turn the pinion. When the correct turning

force is obtained, peen the ring nut using a hammer and

a chisel.

P = 9.2 - 13.8 daN

(20 - 31 pounds)

Differential Assembly

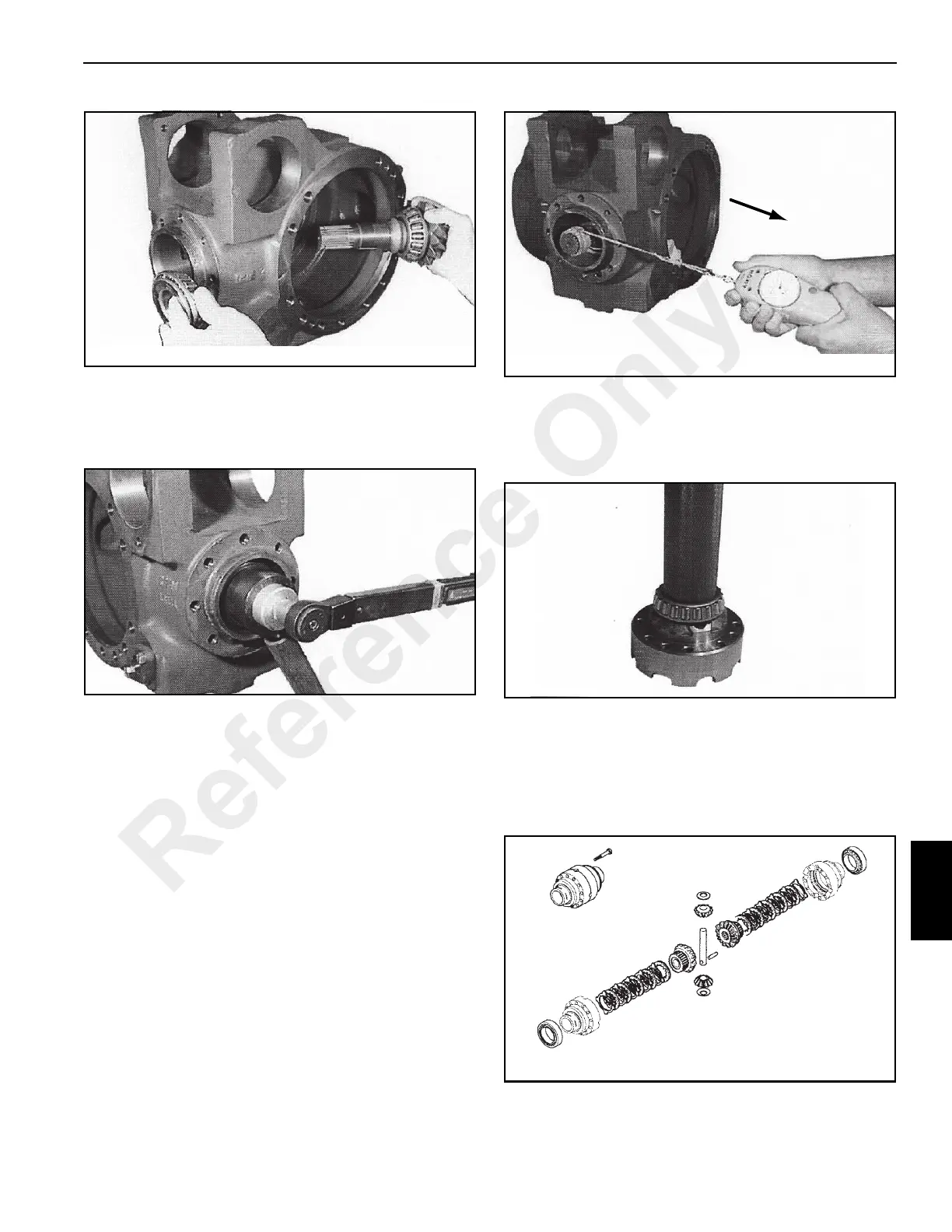

1. Install the bearing cones of the new taper roller bearings

on the differential housing halves (Figure 8-92). Use

SPECIAL TOOL P/N 1901771 and a hammer.

2. Place a housing half on a work bench and assemble all

of its inner components (discs, counterdiscs, planetary

gears, sun gears, thrust washers and pins) as shown in

Figure 8-93.

Join the two housing halves, aligning the reference

marks made during disassembly.

Reference Only

Loading...

Loading...