Maintenance overview

5.1 Maintenance intervals

5 - 2 3 302 756 en Maintenance manual

GMK6400

16.11.2018

The maintenance interval that occurs first determines when the next

maintenance is due.

– You can read the driven km (or mi) on the speedometer.

– You can call up the individual engine and power unit operating hours

(oper. hrs.) of the superstructure on the

ECOS display in the crane cab.

The operating hours of the engine are equivalent to the total operating

hours of the superstructure.

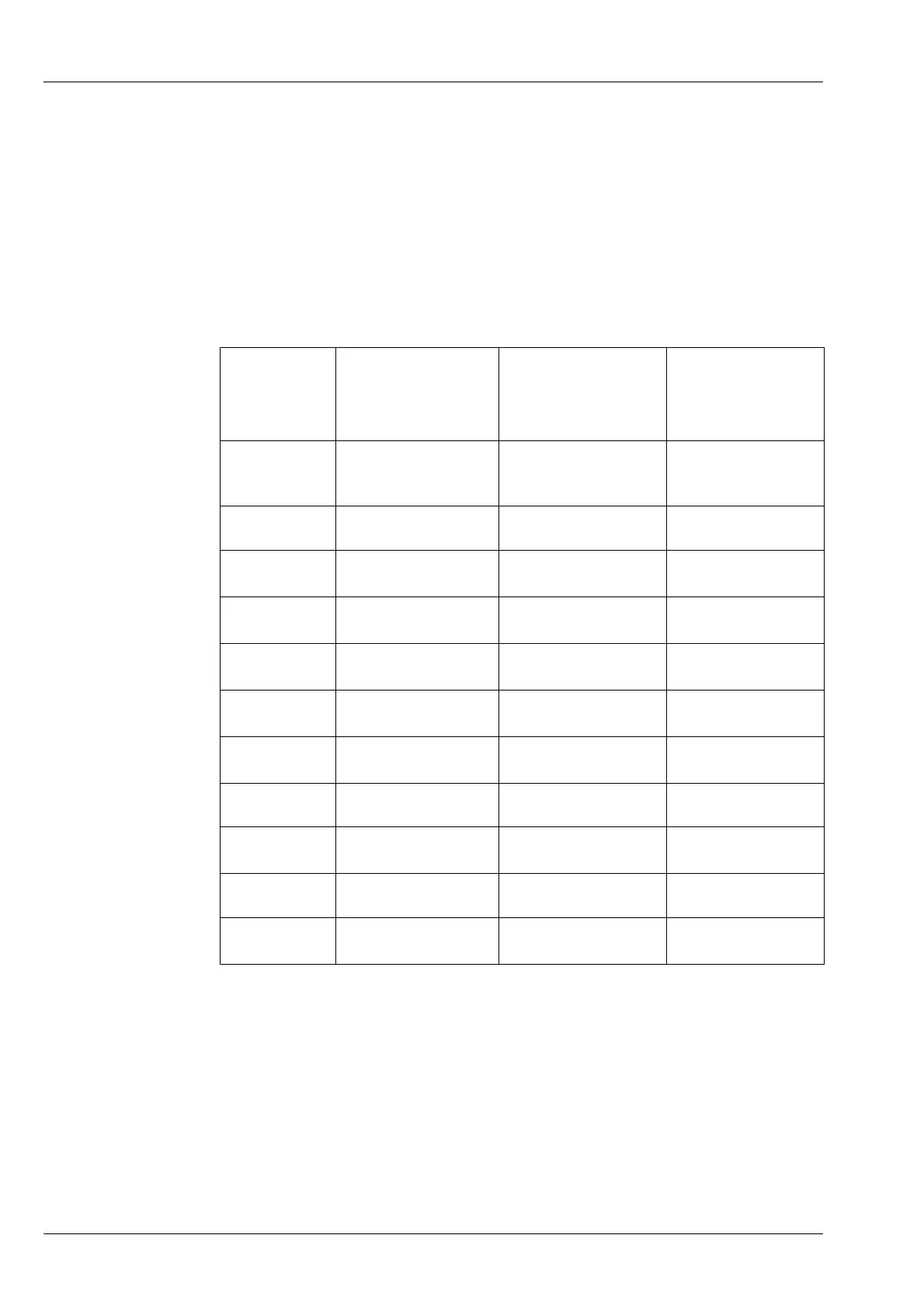

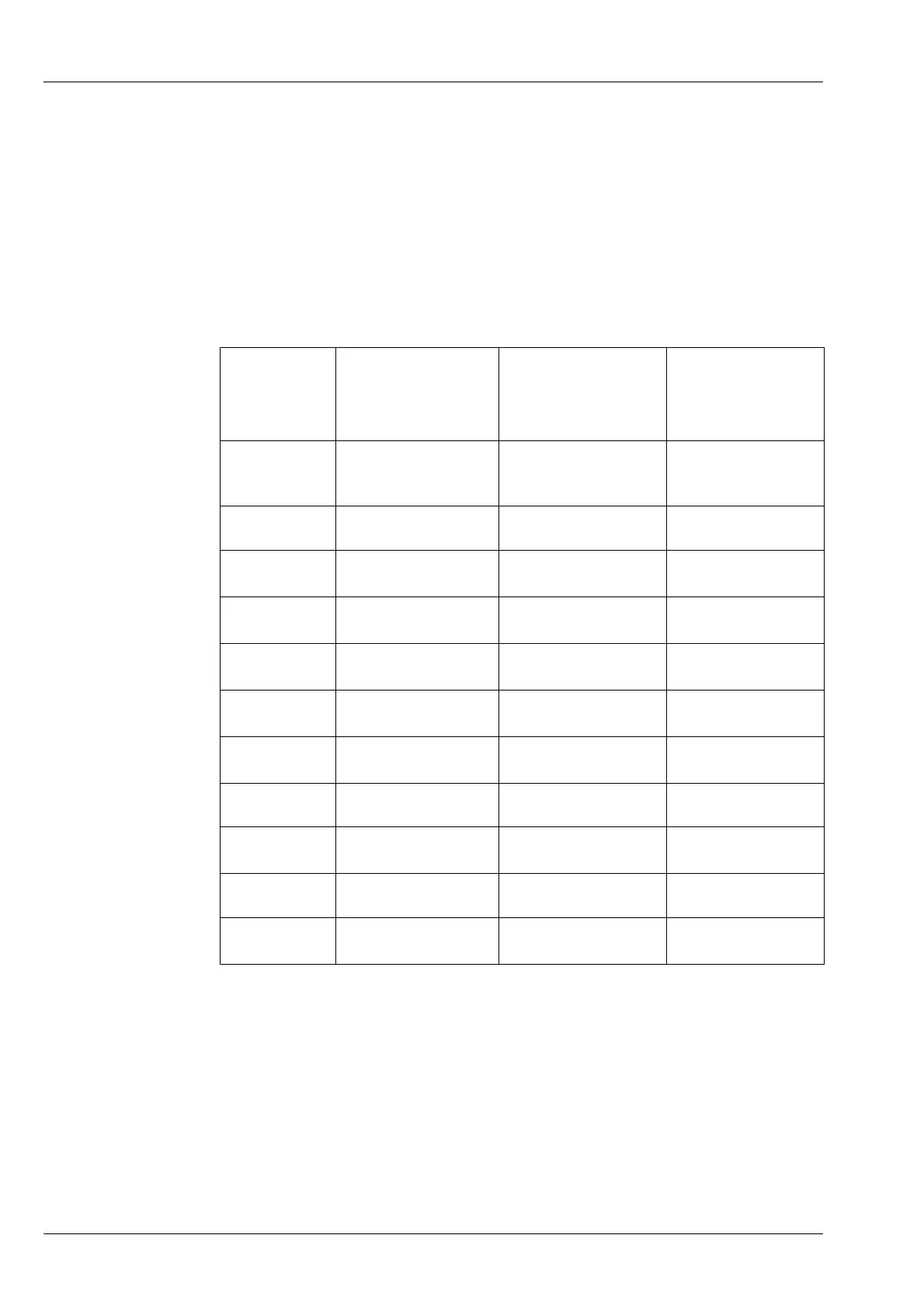

The following table sets out the maintenance intervals for the maintenance

plans:

Please note that the longer-term maintenance plans always incorporate

the shorter-term ones!

Mainte-

nance plans

Maintenance

interval

Driven km (mi)

(carrier)

Operating hours

(oper. hrs.) of

the

engine

(superstructure)

D

Daily / before put-

ting into opera-

tion

— —

W Weekly — —

M 1 monthly

about 2,000

(about 1 240)

about 100

M 3

every three

months

5,000 – 6,000

(3,100 – 3,730)

250

M 6 every six months

10,000 – 12,500

(6,210 – 7,770)

500

M 12

every twelve

months

20,000 – 25,000

(12,430 – 15,530)

1,000

Y 2 every 24 months

40,000 – 50,000

(25,000 – 31,000)

2,000

Y 3 every 36 months — 3,000

Y 5 every 60 months

100,000

(62,000)

5,000

Y 6 every 72 months — 6,000

Y 10 every 120 months

200,000

(124,000)

12,000

Loading...

Loading...