Chapter 2

Periodic maintenance

Section 2 Maintenance and adjustment

2

—

4

Section 2 Maintenance and adjustment

This section describes the service procedure for each

section of the periodic maintenance

VALVE CLEARANCE

In the first 1000km (5 months) and every 4000km

(20 months) thereafter, it should carry out the

inspections.

Inspect

Remove the saddle

Remove the fuel tank

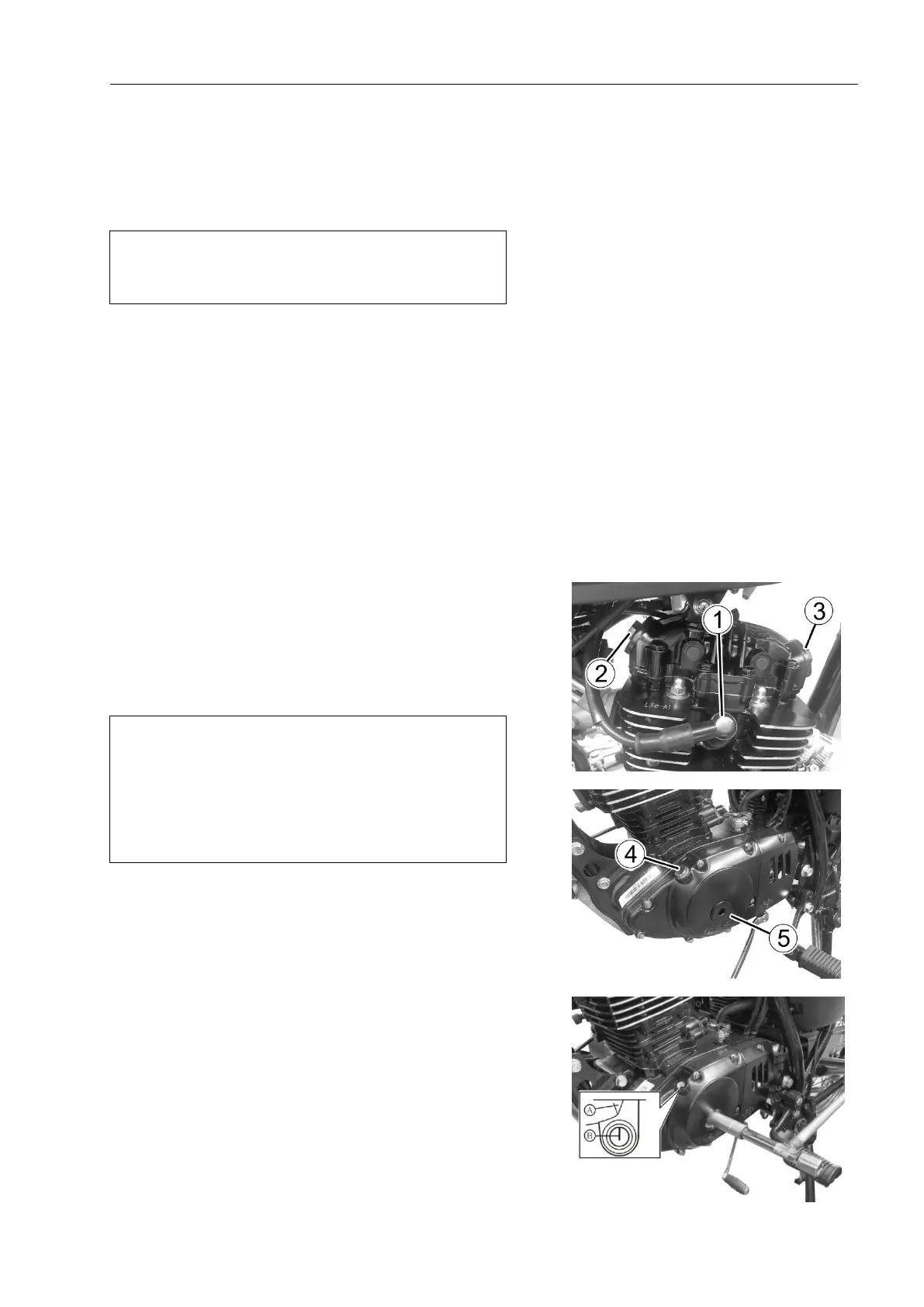

Remove the spark plug①.

Remove the valve inspection cover② and ③.As fig

2.2.1.

The valve clearance specifications of the intake valve

and exhaust valve are different. It needs to check and adjust

the valve clearance in the following conditions:

1) Regular maintenance;

2) Valve mechanism maintenance;

3) Maintenance when removing the camshaft

Valve clearance (when cold)

Intake:0.06—0.08mm

Exhaust:0.10—0.12mm

Note:

When checking or adjusting the valve clearance,

the piston must be at the top dead center (TDC) of

the compression stroke.

The valve clearance can only be checked when

the engine is cold.

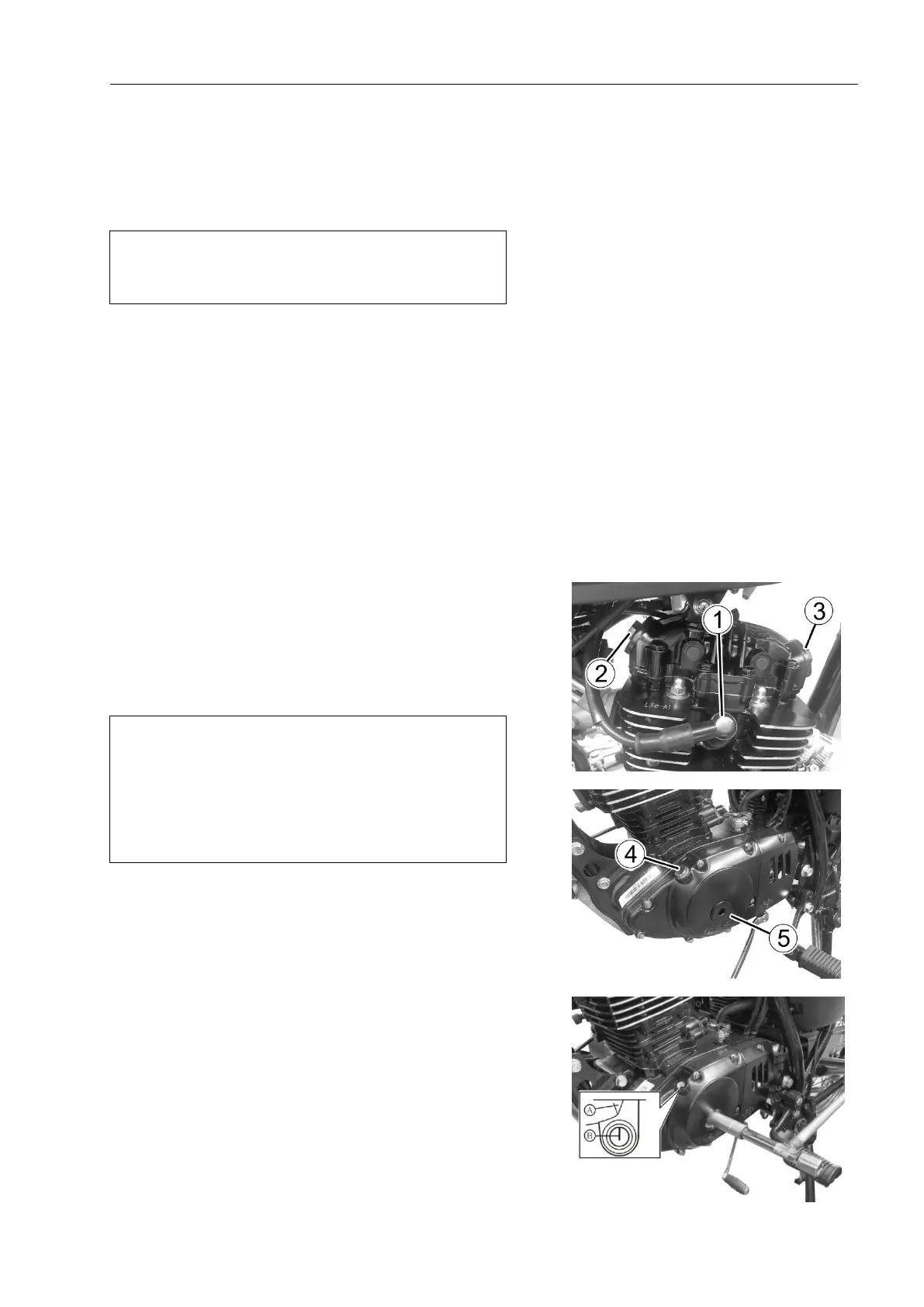

Remove the valve timing screw plug④and magneto

plug ⑤. Fig.2.2.2.

Use the socket wrench to turn the camshaft

counterclockwise, when the intake rocker arm drops and

rises, the piston reaches the top dead center (TDC) of the

compression stroke. (Rotate the crankshaft until the mark B

on the magneto rotor is aligned with the triangle mark A on

the magneto cover).

Fig.2.2.3.

Insert the feeler gauge into the gap between the valve

lifter and adjustment screw on the rocker arm.

If the gap exceeds the specifications, it should be

adjusted according to the following requirements.

As in Fig.2.2.4.

Adjustment

Use a screwdriver and a socket

off-set wrench to adjust the gap.

Loosen the lock nut ⑥.

Insert the feeler gauge into the gap

between the valve stem and adjustment

screw on the rocker arm.

Adjust the valve clearance by

turning the adjustment screw ⑦, while

fixing the lock nut ⑥. As in Fig.2.2.5.

After the adjustment, tighten the

lock nut.

Use the socket off-set wrench to

rotate the crankshaft 720°,and check

whether the gap is within the specified

range.

Fig 2.2.1

Fig2.2.2

Fig 2.2.3

Loading...

Loading...