Chapter 3 Engine Section 5 Engine reassembly

3—50

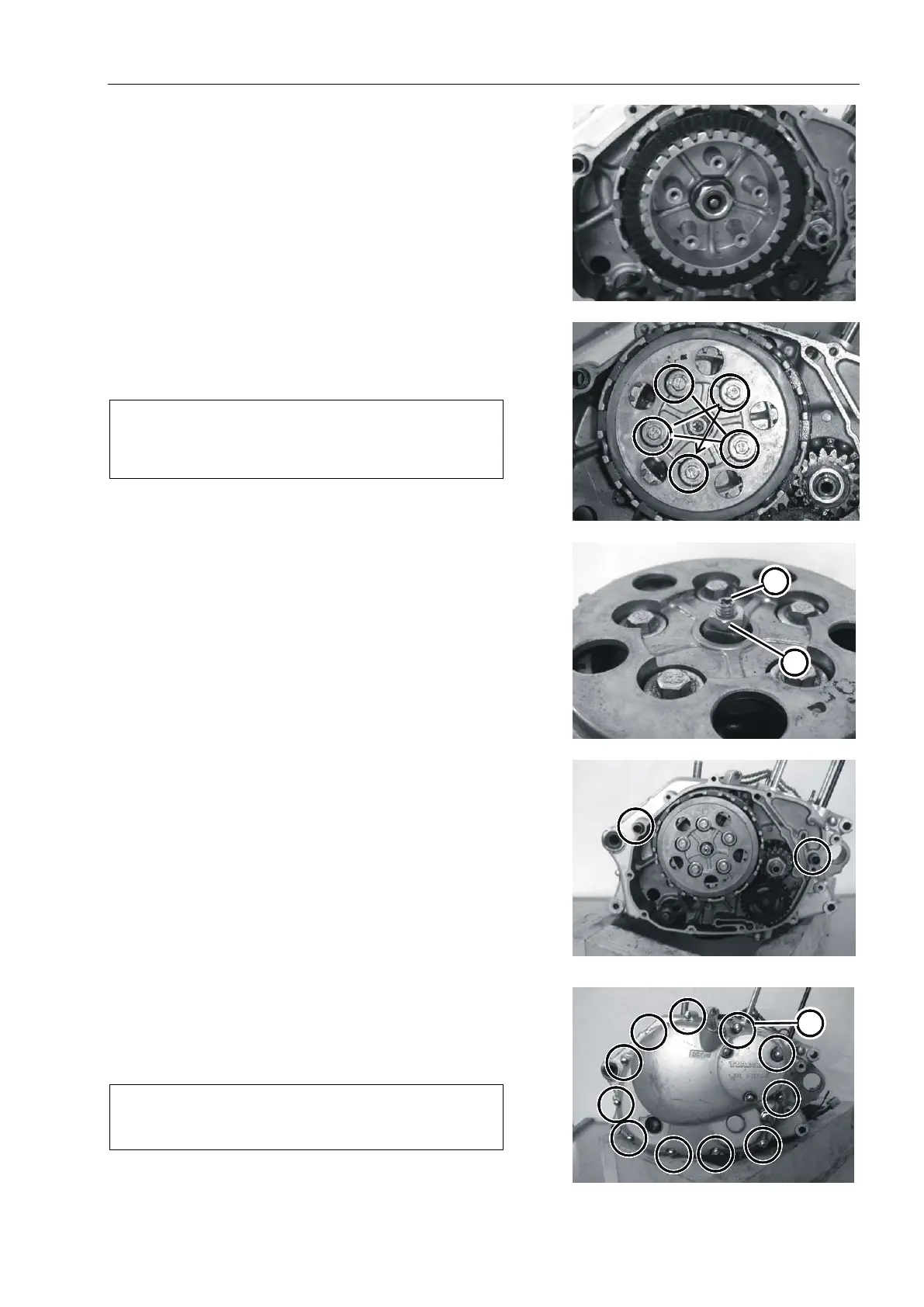

The clutch friction plate in turn according to the active

friction plate, driven plate...

The driven plate and active friction plate are loaded

into the clutch spline sleeve one by one.

As in Fig.3.5.36

Assemble clutch spring disc, clutch spring, install M5

x 16 bolt.

Secure the magneto rotor and cross tighten the clutch

spring mounting bolts.

As in Fig.3.5.37

Note:

Check that the clutch spring disc is installed

correctly.

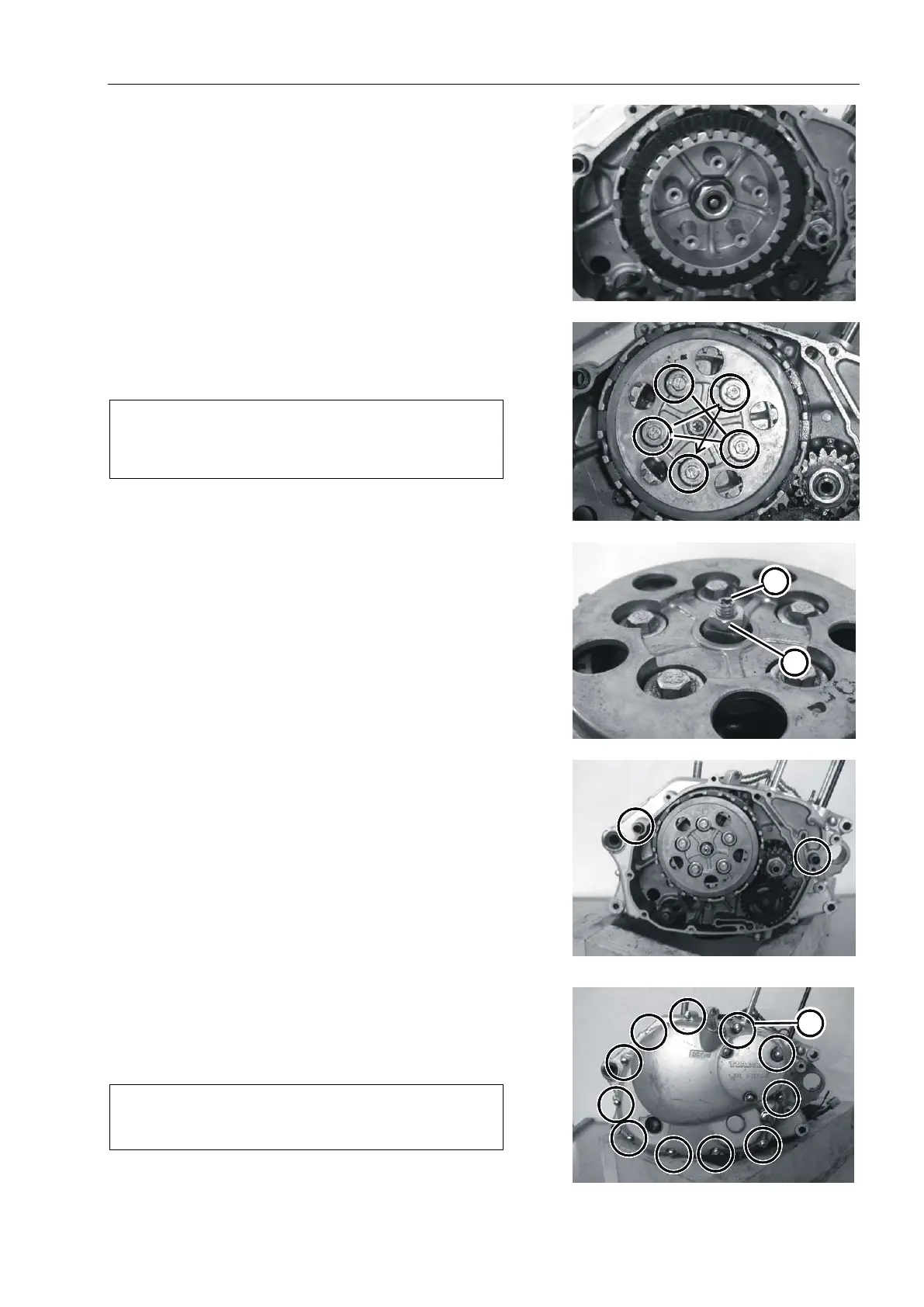

Loosen the positioning nut①and turn the loosened

screw②inward until resistance is felt.

As in Fig.3.5.38

First, the clutch separation camshaft face line is

parallel to the box and box surface, fix the nut ①, adjust

the top wire②, so that it pushes the push rod and the

separation camshaft contact, but not make it rotate, and

then tighten the nut①

Clutch cover

Install two locator pins and new gasket.

As in Fig.3.5.39

Tighten the clutch cover bolts.

As in Fig.3.5.40

Note:

Install the new composite washer on bolt A.

Fig.3.5.36

Fig.3.5.37

Fig.3.5.38

Fig.3.5.39

Fig.3.5.40

Loading...

Loading...