Chapter 2 Periodic maintenance Section 3 Inspection of compression pressure

2

—

19

Section 3 Inspection of compression

pressure

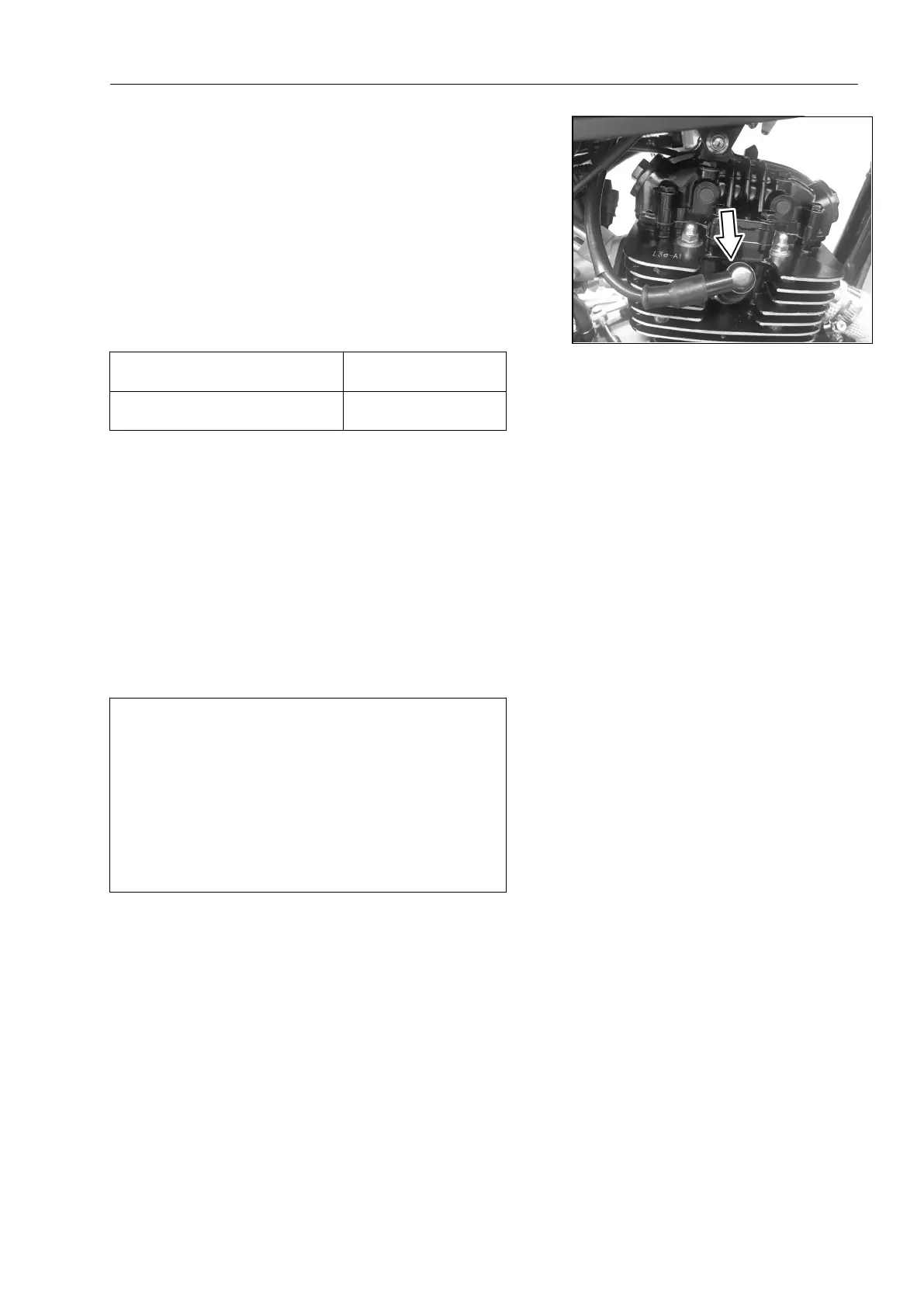

The compression pressure reading is displayed with

the built-in indicator. It usually judges if the cylinder needs

heavy maintenance based on the results of the compression

pressure test. The maintenance records kept at the

distributor include the compression pressure data of each

maintenance.

Compression pressure technical specification

Low compression pressure may indicate any of the

following conditions:

The cylinder wall is over worn;

Piston or piston ring is worn;

Piston ring is stuck in the groove;

The valve seat is not well;

Cylinder cap gasket is defected with crack.

Compression test procedure

Note:

Before testing the engine compression pressure, it

must need to check whether the cylinder cap nut is

tightened to the specified torque and whether the valve is

adjusted properly.

Before the test, it needs to warm up the engine.

It needs to make sure that the battery is fully

charged.

Remove the relevant components, and test the

compression pressure according to the following method:

Install the pressure gauge and adapter in the spark plug

hole to make sure that the connection is tight.

As in Fig.2.3.1

Fully open the throttle handle.

Press the start button and rotate the engine for a few

seconds, then record the maximum reading of the cylinder

compression pressure.

Loading...

Loading...