Chapter 3 Engine Section 4 Inspection and maintenance of engine componenets

3—21

Cylinder cranium

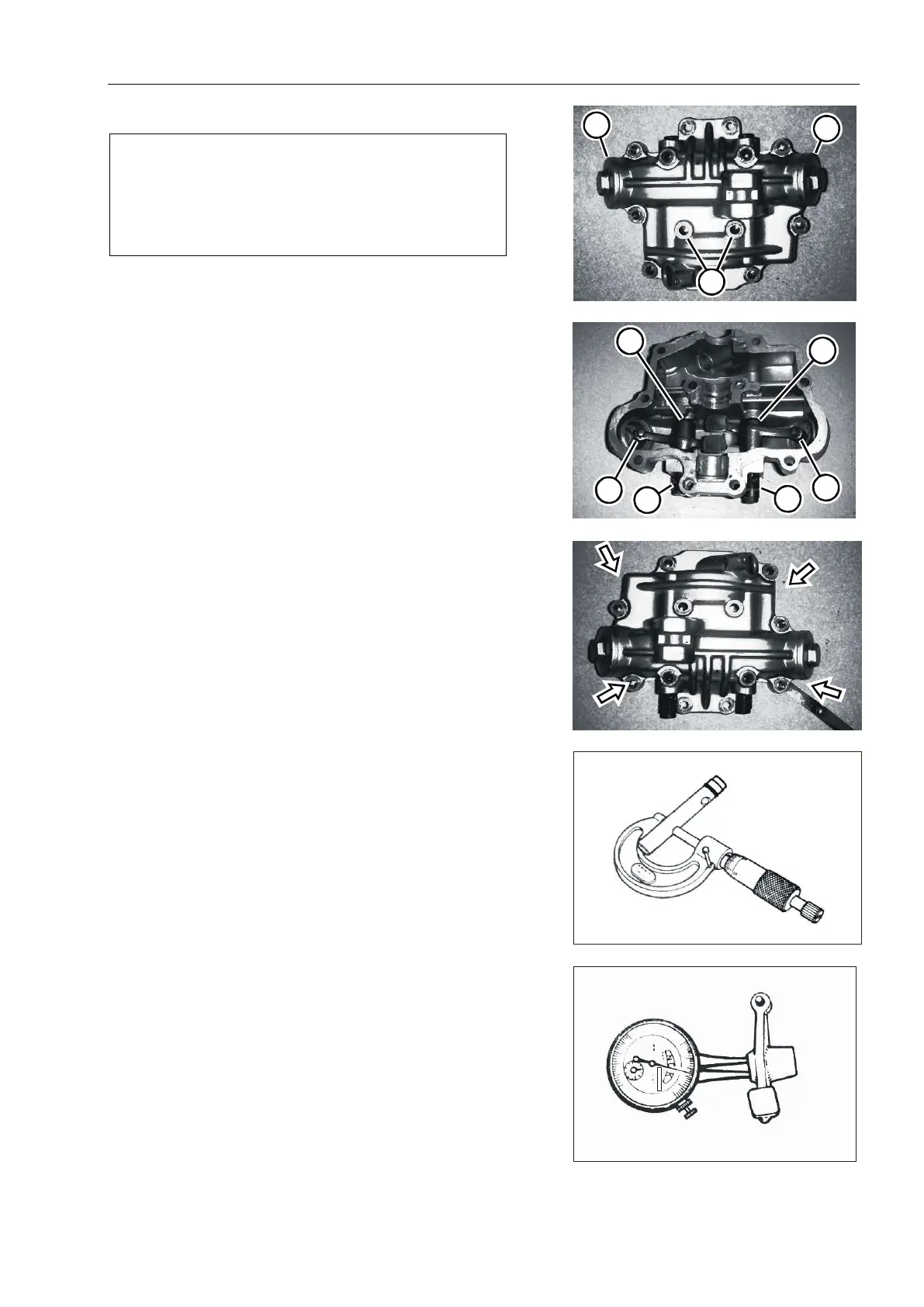

As in Fig.3.4.10

Note:

Mark the position of each removed component.

The components shall be placed in groups (i.e.,

intake or exhaust) so that they can be assembled in

place.

Remove

Remove valve inspection hole cap , .① ③

As Fig. 3.4.10

Remove rocker arm shaft bolts②.

Remove rocker arm shaft④

Remove the rocker arm⑤and waveform washer ⑥).

As in Fig.3.4.11

Cylinder head cover deformation

After removing the sealant from the mating surface of the

cylinder head cover, place the cylinder head cover on a flat

plate and check for deformation with a feeler gauge.

Check each point according to the diagram.

As Fig. 3.4.12

Tools: feeler gauge Limit of use: 0.05mm

If the deformation exceeds the limit, replace the cylinder

head.

Outer diameter of rocker arm shaft (O, D)

Measure rocker shaft diameter.

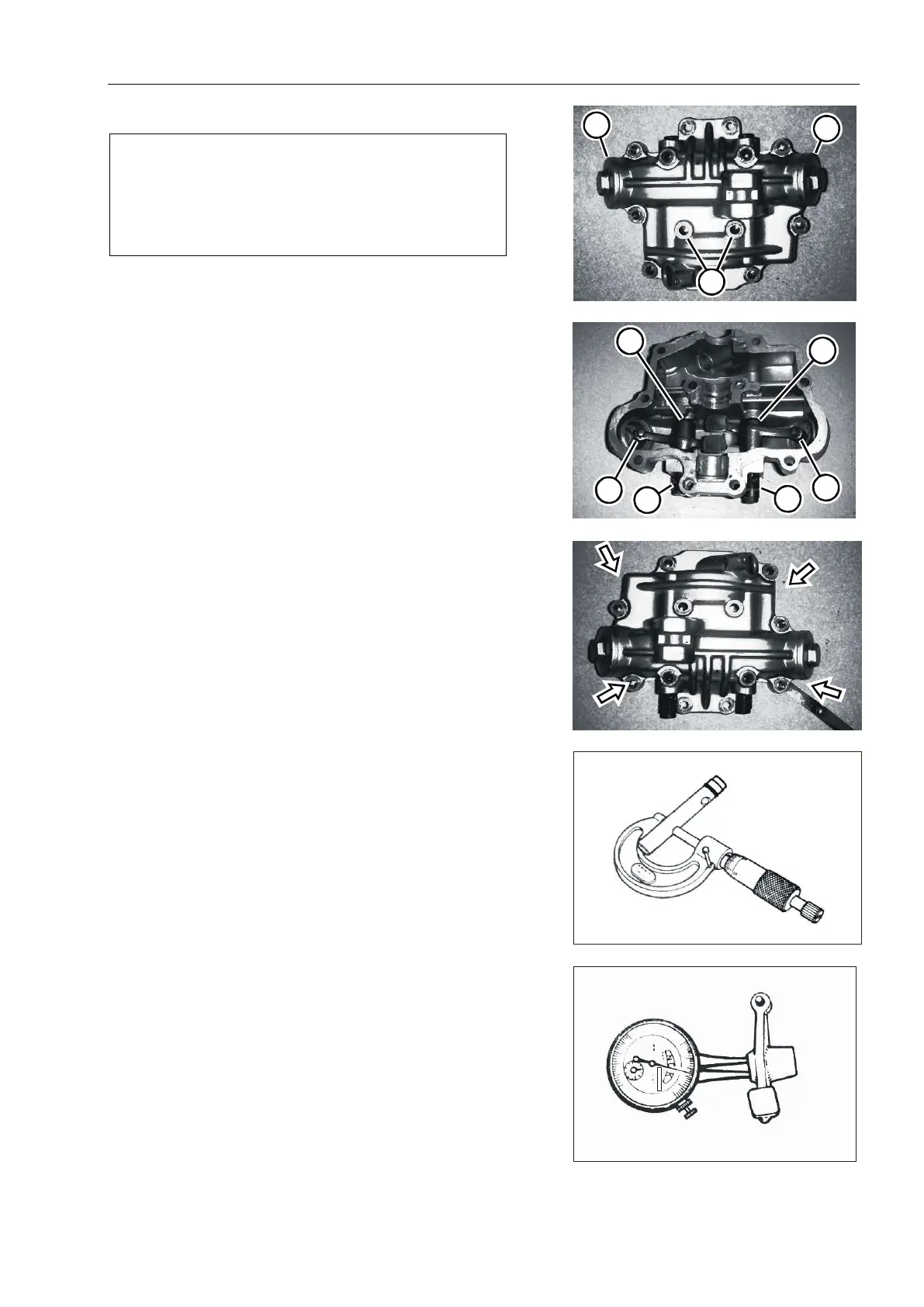

As Fig. 3.4.13

Tools: micrometer calipers (0 -- 25 mm)

Standard: 11.979 -- 11.990 mm

Inner diameter of rocker arm (1, D)

Measure the inner diameter of rocker arm and check the

wear of camshaft contact surface.

As Fig. 3.4.14

Standard: 12.000-12.018 mm

Fig.3.4.10

1

Fig.3.4.11

5

4

4

6

Fig.3.4.12

Fig.3.4.13

Fig.3.4.14

Loading...

Loading...