Chapter 4 EI system diagnosis Section 1 Maintenance Precautions

4—1

Chapter 4 EI system diagnosis

Section 1 Maintenance Precautions

CONNECTOR / COUPLER

When separating the cylindrical plug connection, hold

the terminal and do not pull the lead.

When the access plug is connected, push it in and

firmly connect.

Inspect each terminal for corrosion and contamination

As in Fig.6.1.1.

For lock connectors, be sure to open the lock before

disassembling.

When the connector is plugged in, it can be pushed in

until it "clicks" and locks.

When disassembling the connector, be sure to hold the

connector and do not pull the lead.

Inspect each terminal on the connector / coupler

for looseness or bending

Inspect each terminal for corrosion and contamination

As in Fig.6.1.2

Inspect each lead wire circuit for poor connection by

shaking it by hand lightly. If any abnormal condition is

found,

repair or replace.As in Fig.6.1.3

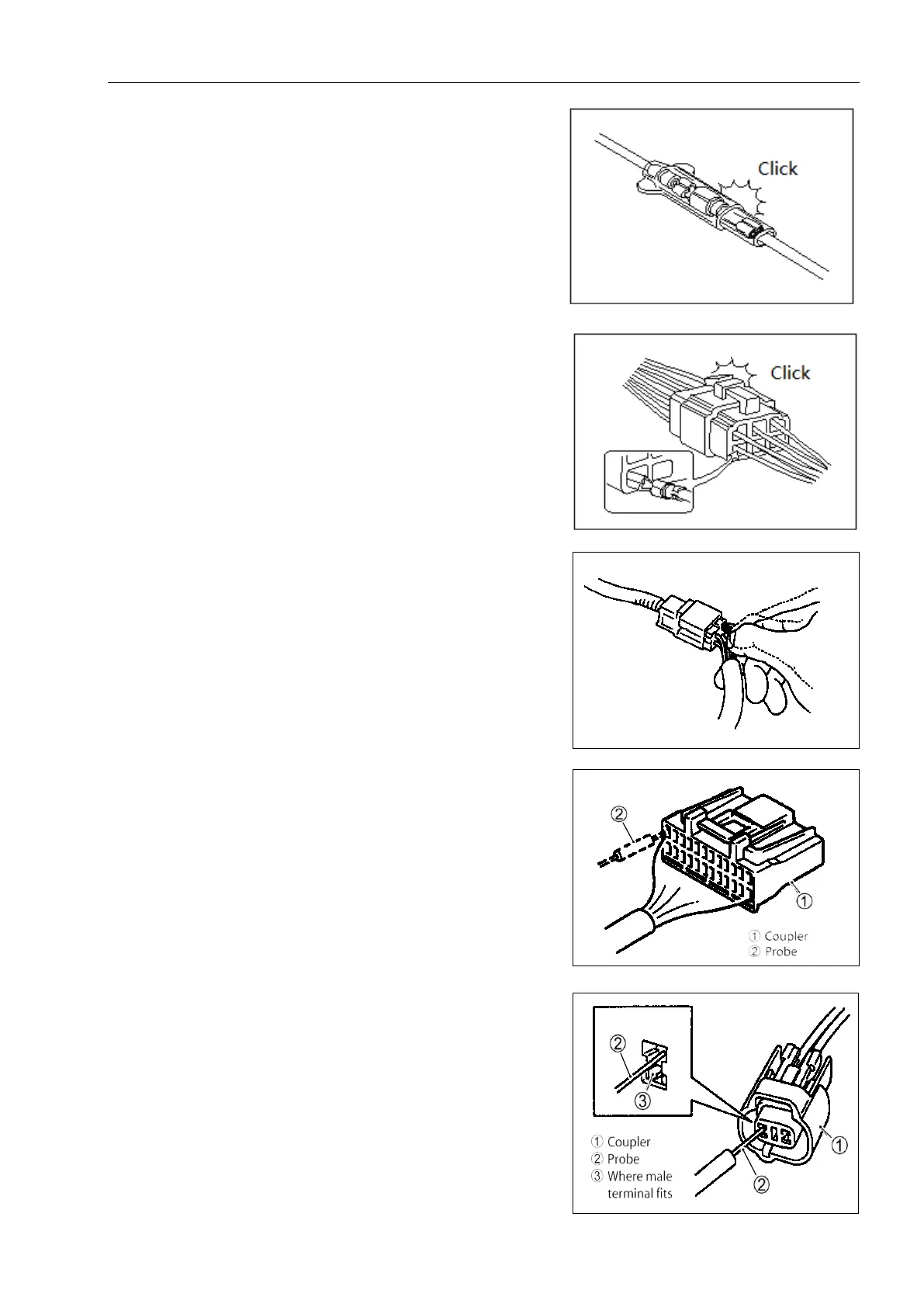

When taking measurements at electrical connectors

using a tester probe, be sure to insert

the probe from the wire harness side (backside) of the

connector / coupler.

As in Fig.6.1.4

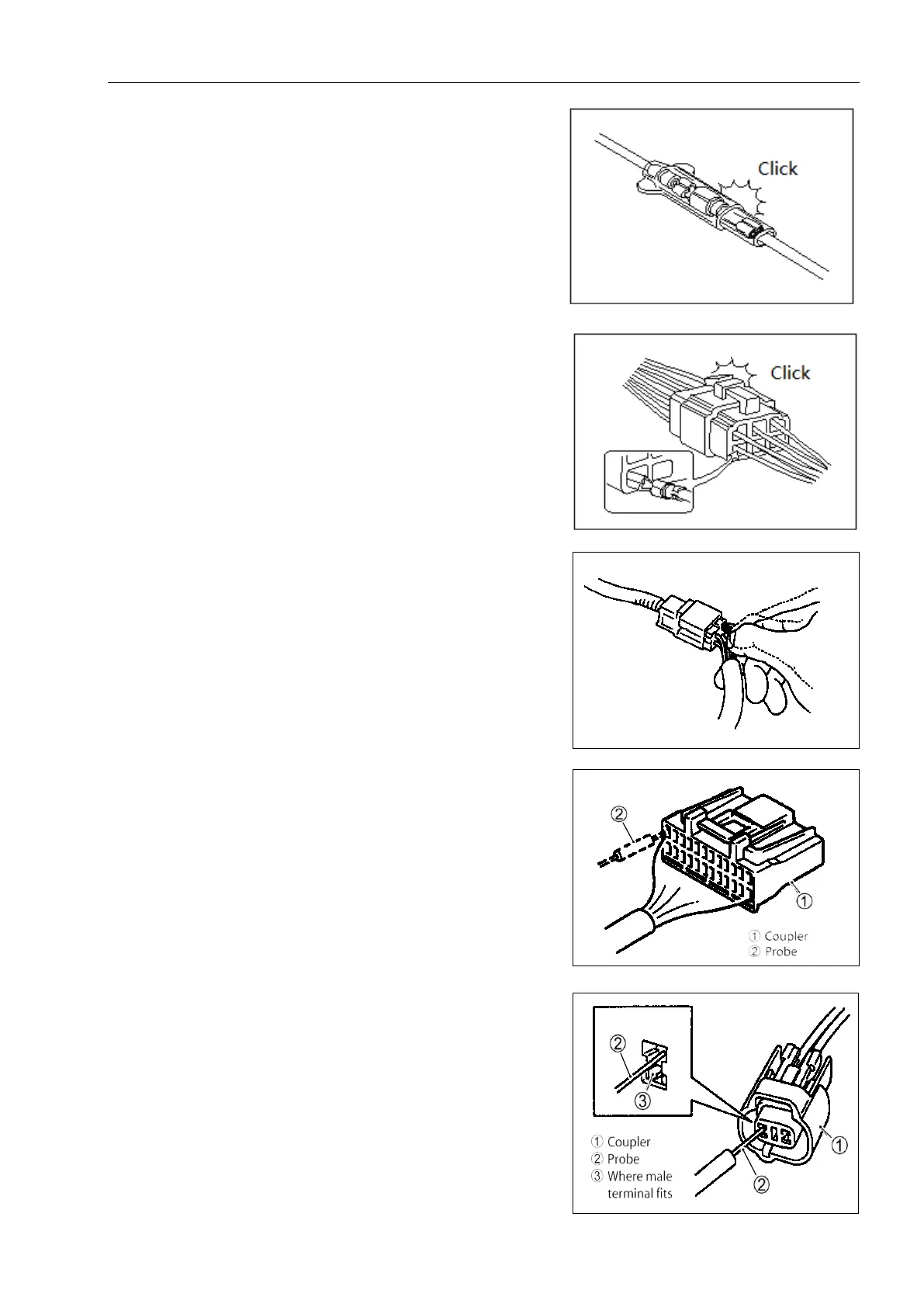

•When connecting meter probe from the terminal side

of the coupler (connection from harness side not being

possible), use extra care not to force and cause the male

terminal to bend or the female terminal to open. As in

Fig.6.1.5,Connect the probe as shown to avoid opening of

female terminal.

Never push in the probe where male terminal is

supposed to fit.

Inspect each terminal on the connector / coupler

for looseness or bending

Inspect each terminal for corrosion and contamination

Fig.6.1.1

Fig.6.1.2

Fig.6.1.3

Fig.6.1.4

Fig.6.1.5

Loading...

Loading...