Chapter 3 Engine Section 5 Engine reassembly

3—57

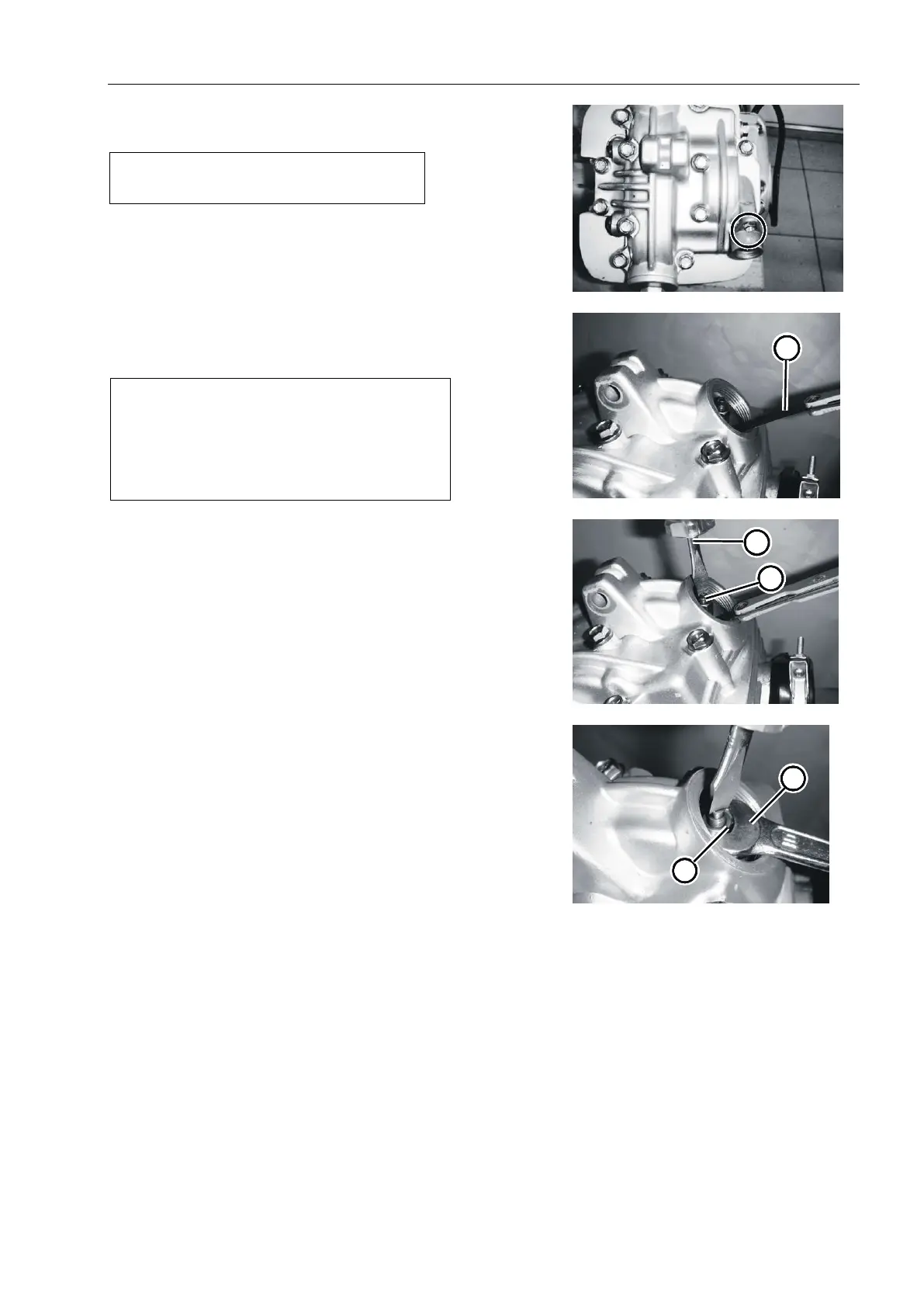

Install the connecting sleeve.

As in Fig.3.5.71

Note:

Be sure to check valve clearance.

Check valve clearance

Inlet valve and exhaust valve clearance specifications

are not the same.

Valve clearance (cooling machine) :

Admission: 0.06 0.08 mm

Exhaust: 0.10 0.12 mm

Align line A on the magneto rotor with mark B on the

magneto cover.

Turn the crankshaft counterclockwise with a socket

wrench, and the piston reaches TDC of the compression

stroke as the intake rocker arm falls and rises.

Turn the crankshaft until line B on the magneto rotor

aligns with triangle mark A on the magneto housing.

If there is no clearance, turn the crankshaft once more.

Insert the plug rule into the gap between the stem ①

end and the adjusting screw on the rocker arm.As in

Fig.3.5.72

If the clearance exceeds the specification requirements,

the following requirements should be adjusted.

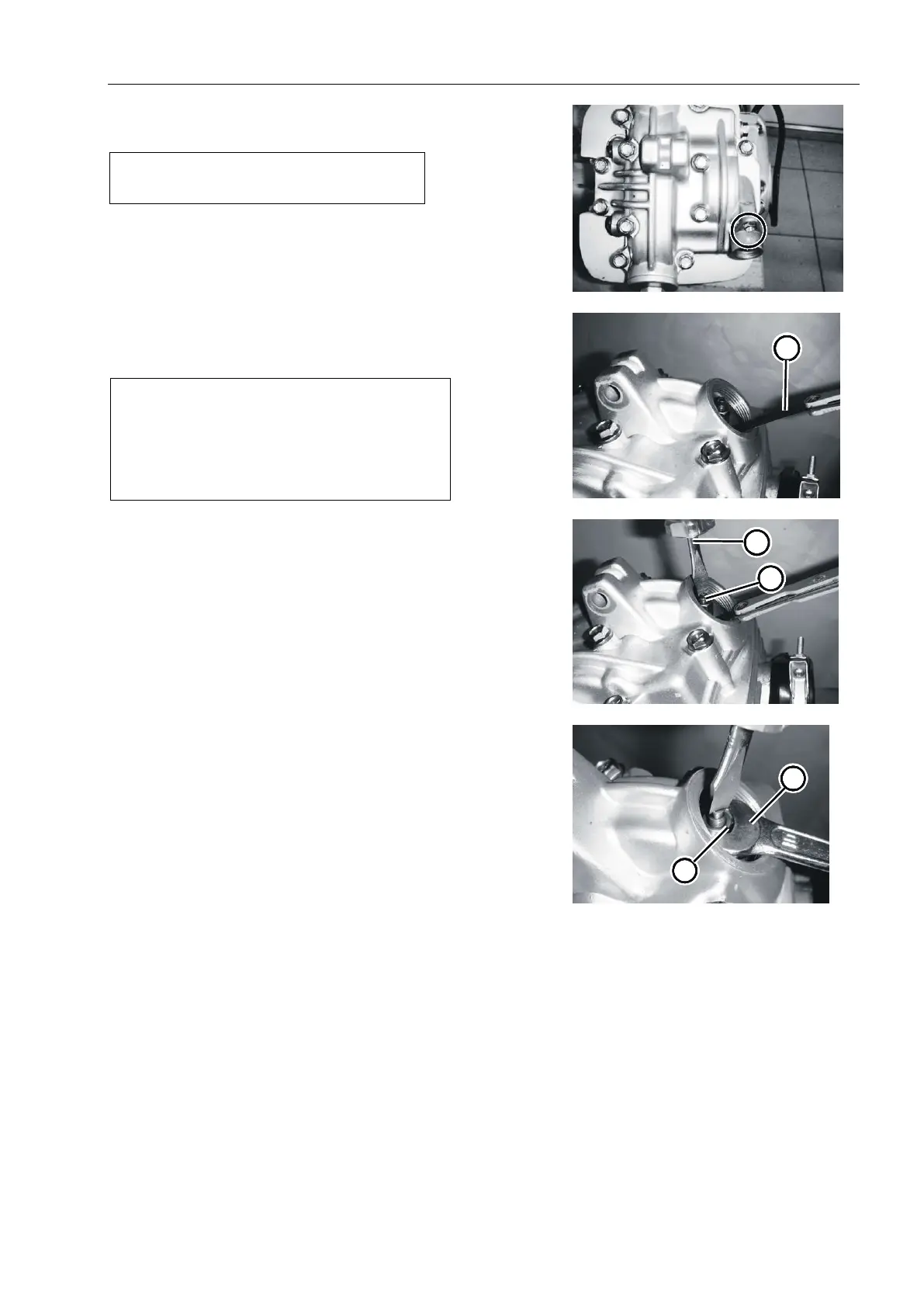

Adjustment

Loosen the locking nut ⑤.

To use a screwdriver adjusting screw , when ② ③

pulling the feeler ruler is tight, the adjustment ends.As Fig.

3.5.73

Stop turning the adjusting screw and tighten the ③

locking nut ⑤with a spanner④ at the same time to adjust

the valve clearance.As Fig. 3.5.74

Install valve inspection cap, observation hole plug and

magneto cap.

Fig.3.5.71

Fig.3.5.72

Fig.3.5.73

Fig.3.5.74

5

Note:

When checking or adjusting valve

clearance, the piston must be at TDC of the

compression stroke.Check valve clearance

only when the engine is cool.

Loading...

Loading...