Chapter 2

Periodic maintenance

Section 2 Maintenance and adjustment

2

—

14

Continuously pressurized rear brake pedal by hand for

exhaust;

Keep pressurizing and refueling until the brake is

obviously felt, then press the pedal and release the exhaust

valve C for exhaust work;

Then screw the vent valve, squeeze the brake lever

and open the vent valve again (note: pedal downpressure

shall not be lifted before the vent screw is tightened during

the exhaust process).

The process is repeated until the liquid flows into the

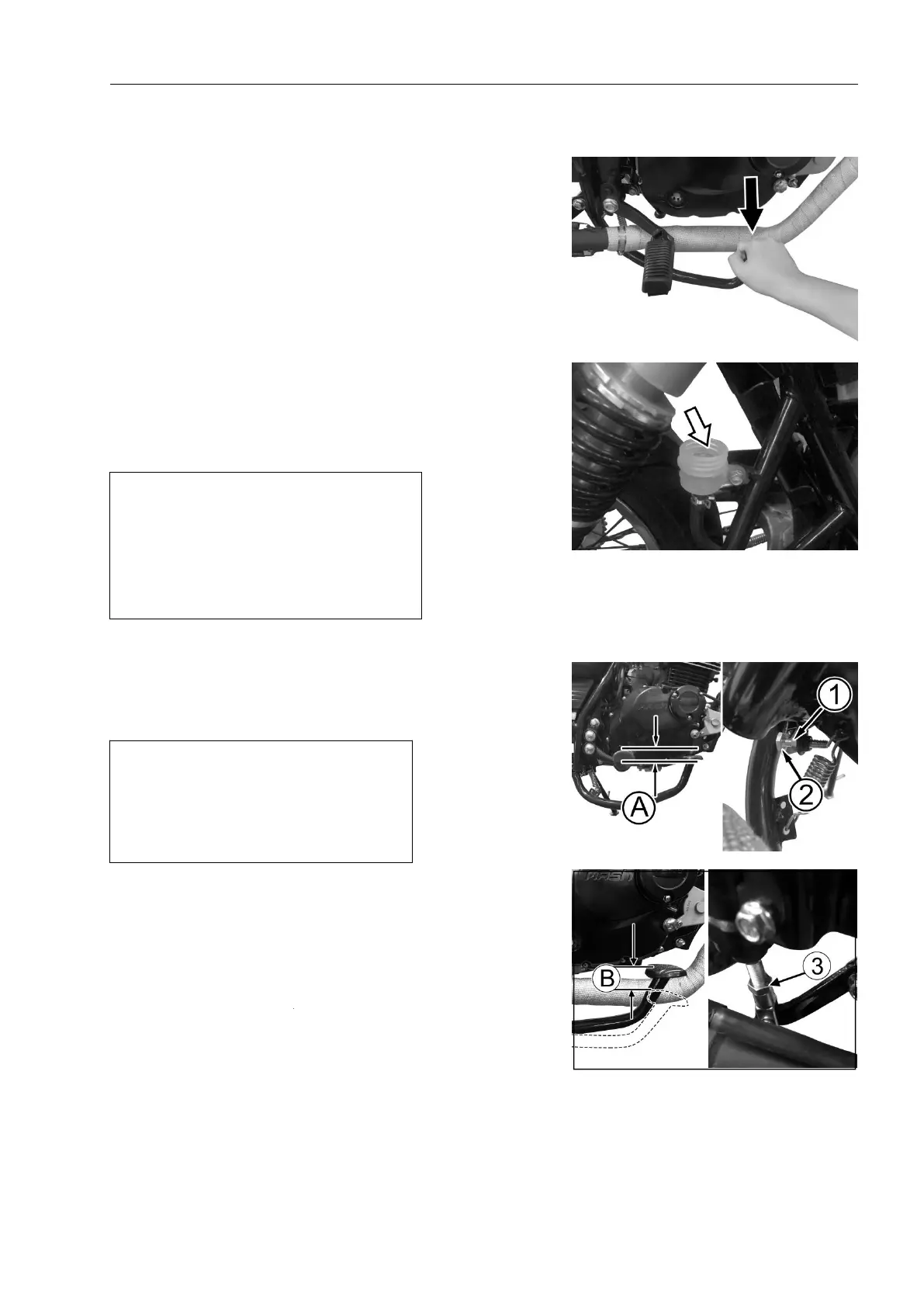

container and there are no more bubbles.As Fig. 2.2.41.

The linkage vent valve B in the middle of the front

brake pump body shall continue exhaust treatment

according to the same steps above.

Note:

When air is bled from the brake

system, brake fluid should be

replenished at any time in order to

ensure that fluid can appear in the fluid

reservoir.

Close the bleeding valve, and then pull out the hose. Fill

the brake fluid to within the calibration line of the oil cup.

Exhaust valve torque:7.5N.(0.75kg.m)

Note:

The braking fluid should be

handled carefully: this fluid will

chemically react with painting and

rubber materials.

After completing the operations, put on the dust cap of the

bleeding valve.

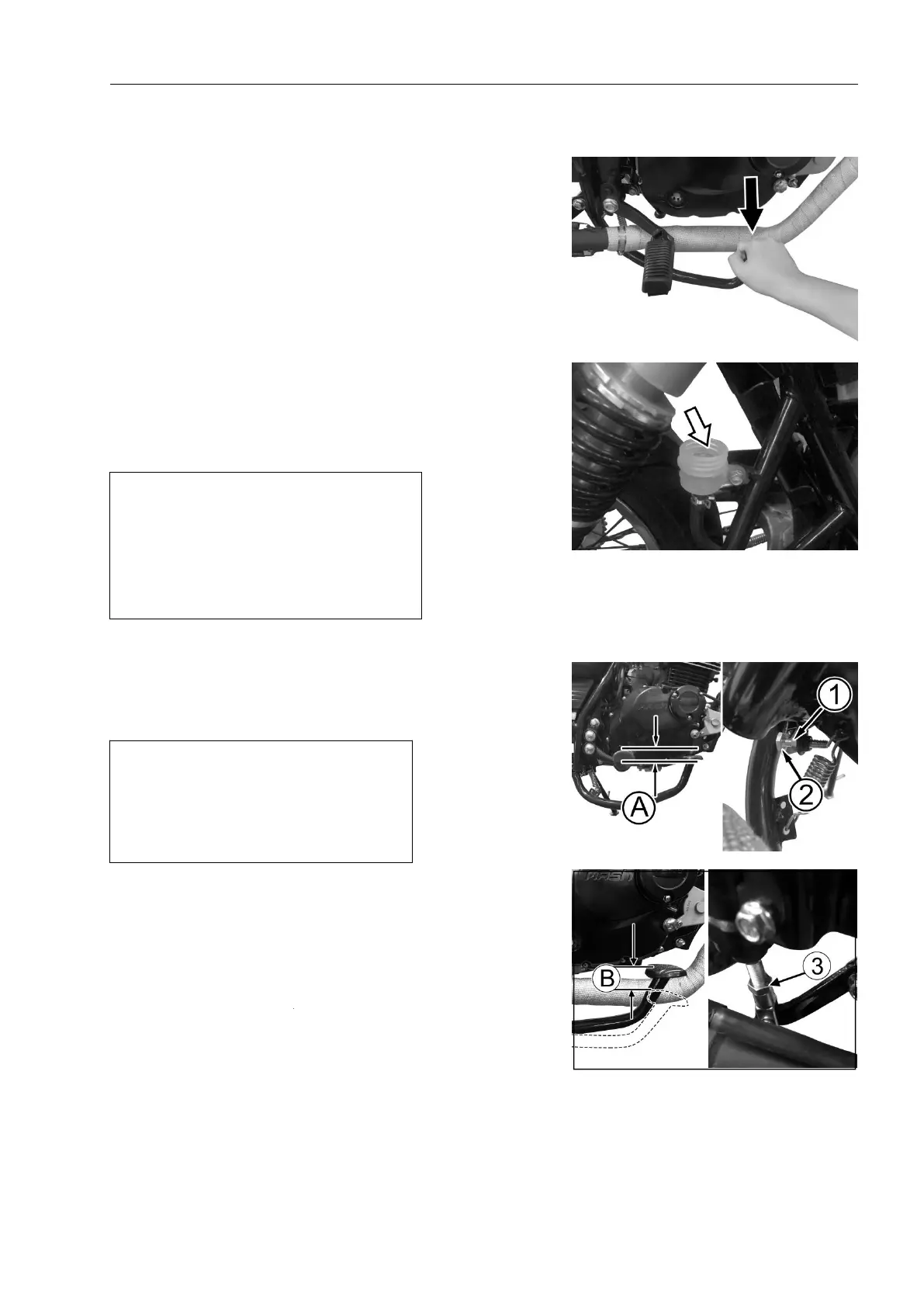

Rear braking pedal height

Loosen the lock nut①.

Regulate the height

of the braking pedal by

rotating the adjustment bolt ②, and make the position of

20mm below the upper surface of the footrest.

As if Fig.2.2.42.

Adjustment of rear brake

Turn the adjustment nut③ to adjust the free stroke to

20-30mm. As in Fig.2.2.43.

Fig.2.2.41

Fig.2.2.42

Fig.2.2.42

Fig.2.2.43

Loading...

Loading...