18

BEFORE USE

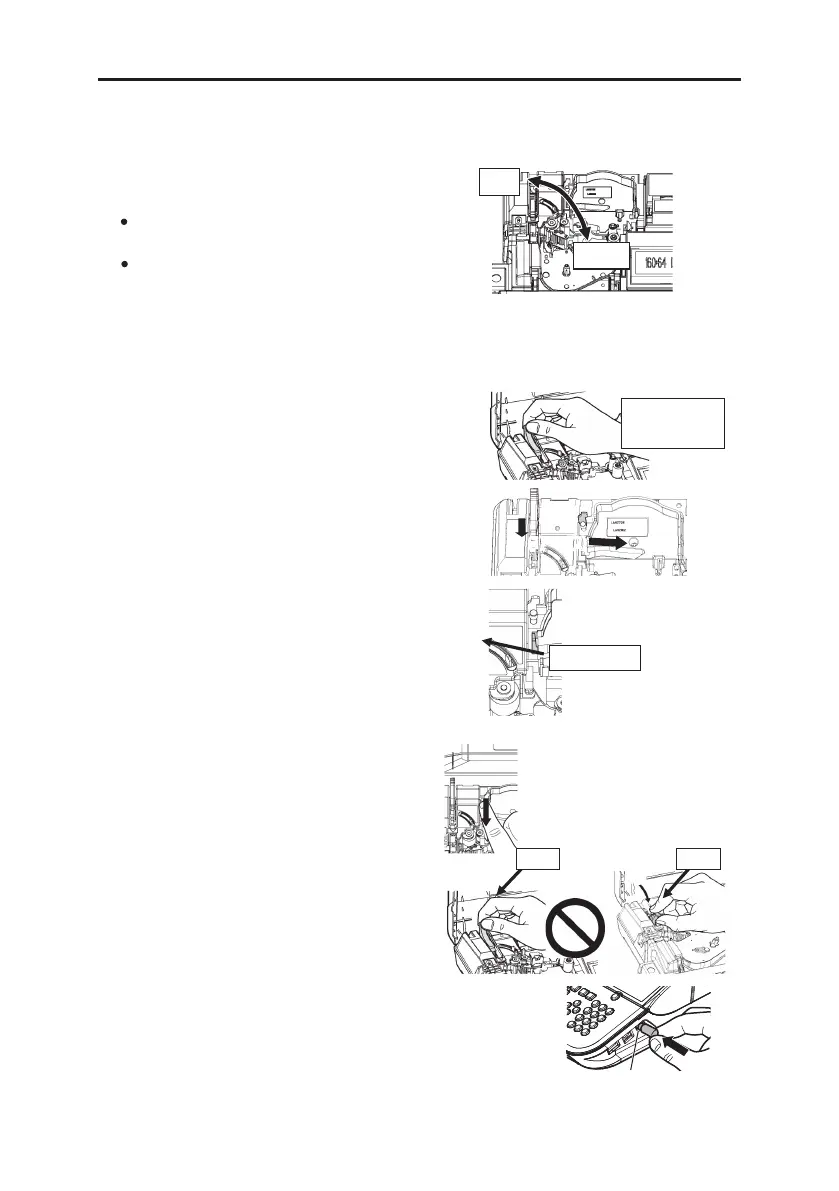

4-8 ADJUSTING THE HALF CUTTING DEPTH

Half cutting depth can be adjusted with the ”Half cutting depth adjustment lever”, when half

cutting depth is not adequate.

Note:

When printing on tubes, the lever has to

be

positioned on the “TUBE.”

When printing on tape or ID plate, the lever

has to be positioned on the “TAPE” choice.

.

4-9 SW

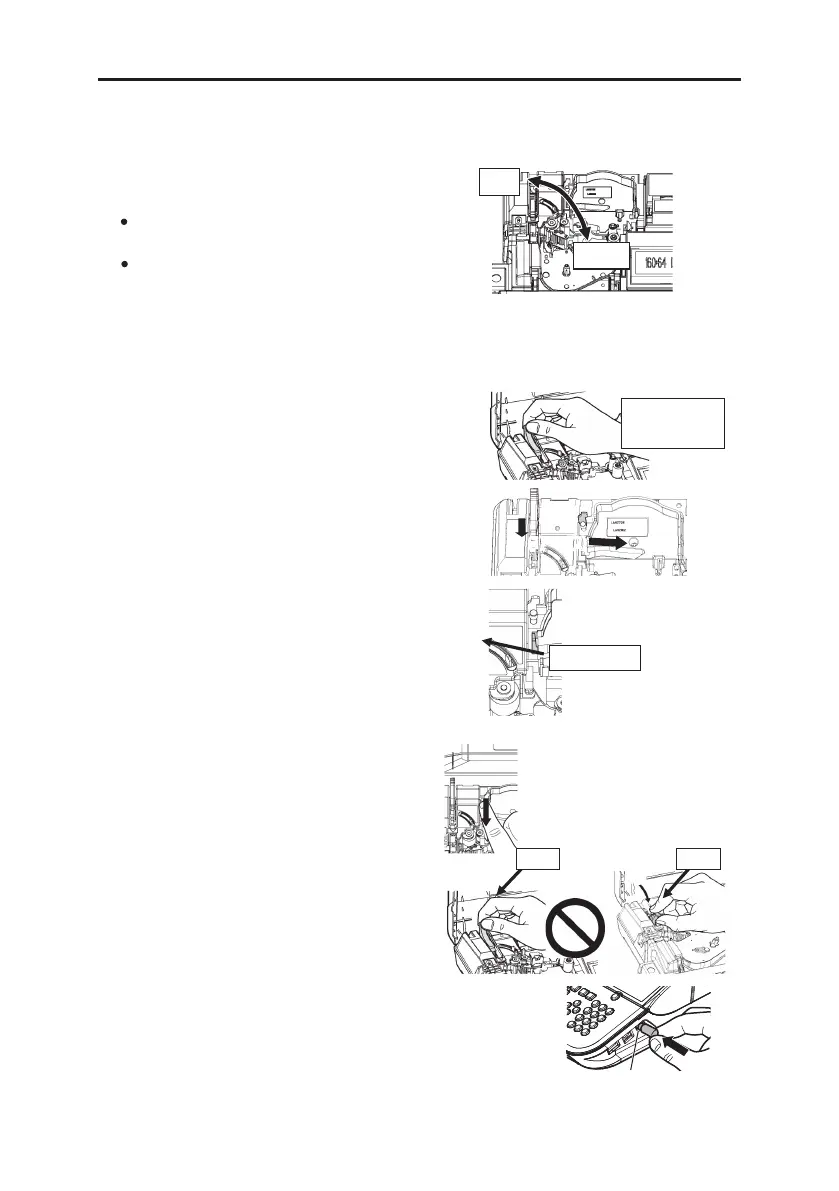

4-10 CONNECTING AC ADAPTER

ITCHING THE PRINTING PRESSURE

Printing pressure can be adjusted with the “Printing pressure switching lever.”

Note: You don’t need to change the strength unless the printed result is too dark.

(Changing from the standard pressure to the low pressure)

1. Check that the release lever is at the

middle position. (The lever is standing)

2. While pressing the lock button, then slide

the printing pressure switching lever to

the right.

3. Now, the strength of the printing pressure

is low.

(Changing from the low pressure to the standard pressure)

1. Ch

1. Insert the AC adapter jack firmly into the connection part on

the right side of the main unit.

eck that the release lever is at the

middle position. (The lever is standing).

2. P

2. Insert the power plug of the AC adapter into the outlet/power

point .

ress the lock button.

Note: Don’t change the head pressure when

the head release lever is positioned as

the figure (“Open” position or “Close”

position).

Deep

Shallow

he release lever i

standing.

Low po

AC adapter

connection

sition

“Open” “Close”

Loading...

Loading...