ENGINE MECHANICAL SERVICE MANUAL NUMBER 22

Page 3A-110 90-860074--1 FEBRUARY 2002

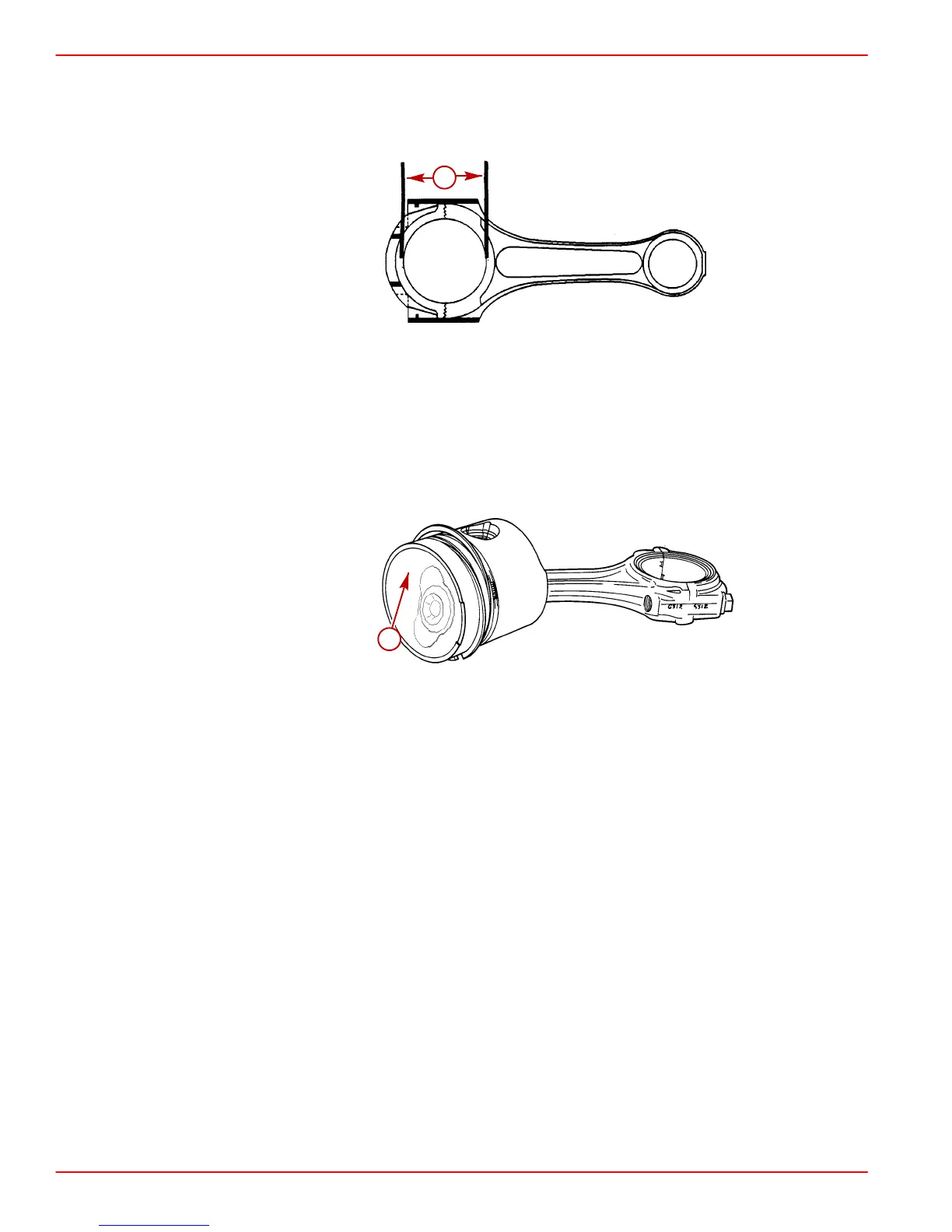

4. Measure connecting rod crank pin bore with a dial bore gauge or inside micrometer for

out-of-round or excessive wear. Crank pin bore must be 57.563-57.582 mm

(2.2662-2.2670 in.). Replace connecting rod if measurement exceeds allowable

dimension by 0.02 mm (.0008 in.).

70397

a

a-Rod Crank Pin Bore

PISTONS

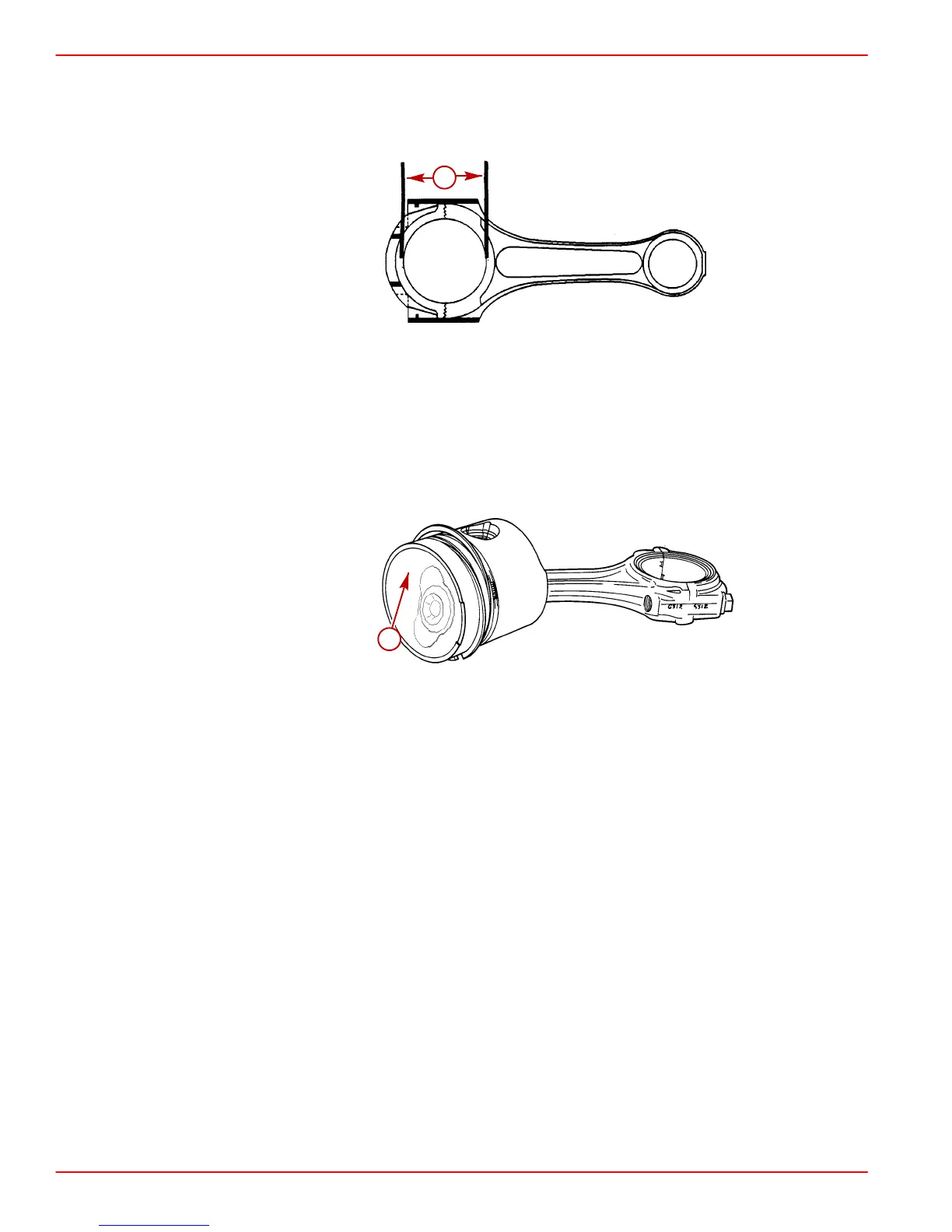

IMPORTANT: The D-Tronic Engines should have only Class A pistons. Determine the

Class of piston by looking on top of piston (as shown following) or by examining the

underside of the cylinder liner Refer to Cylinder Liner - Identification for reference

details.

70296

a

a-Location for Class A Designation

1. Inspect piston for cracked ring lands, skirts or pin bosses, wavy worn ring lands, scuffed or

damaged skirts or eroded areas at top of piston. Replace pistons which are damaged or show

signs of excessive wear. (Refer to Step 6, following.)

2. Inspect grooves for nicks or burrs that might cause rings to hang up.

3. Except on upper ring groove of pistons (refer to Step 5. following), insert edge of rings

into respective piston ring groove and roll ring entirely around the groove to make sure

that ring is free. If binding occurs at any point, determine cause. If caused by ring groove,

remove by dressing with a fine cut file. Do NOT remove excess material. Verify with a

feeler gauge and compare to specifications. If binding is thought to be a distorted ring,

check with a new ring.

Loading...

Loading...