ENGINE MECHANICAL

SERVICE MANUAL NUMBER 22

90-860074--1 FEBRUARY 2002 Page 3A-149

INSPECTION

1. Visually inspect rear portion of flywheel housing and flywheel housing for cracks, holes,

and excessive wear.

2. Inspect O-ring on rpm speed sensor.

3. Replace if necessary.

INSTALLATION

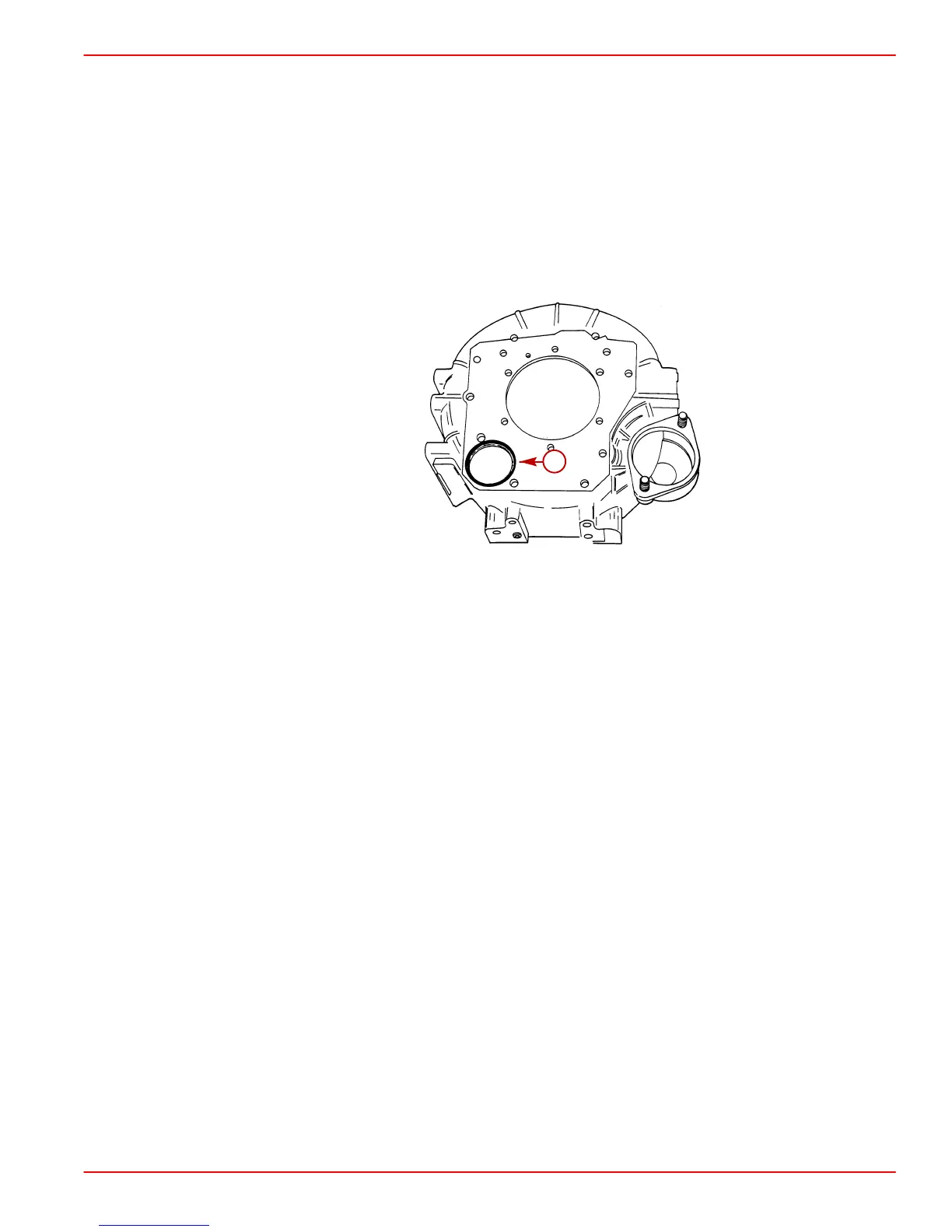

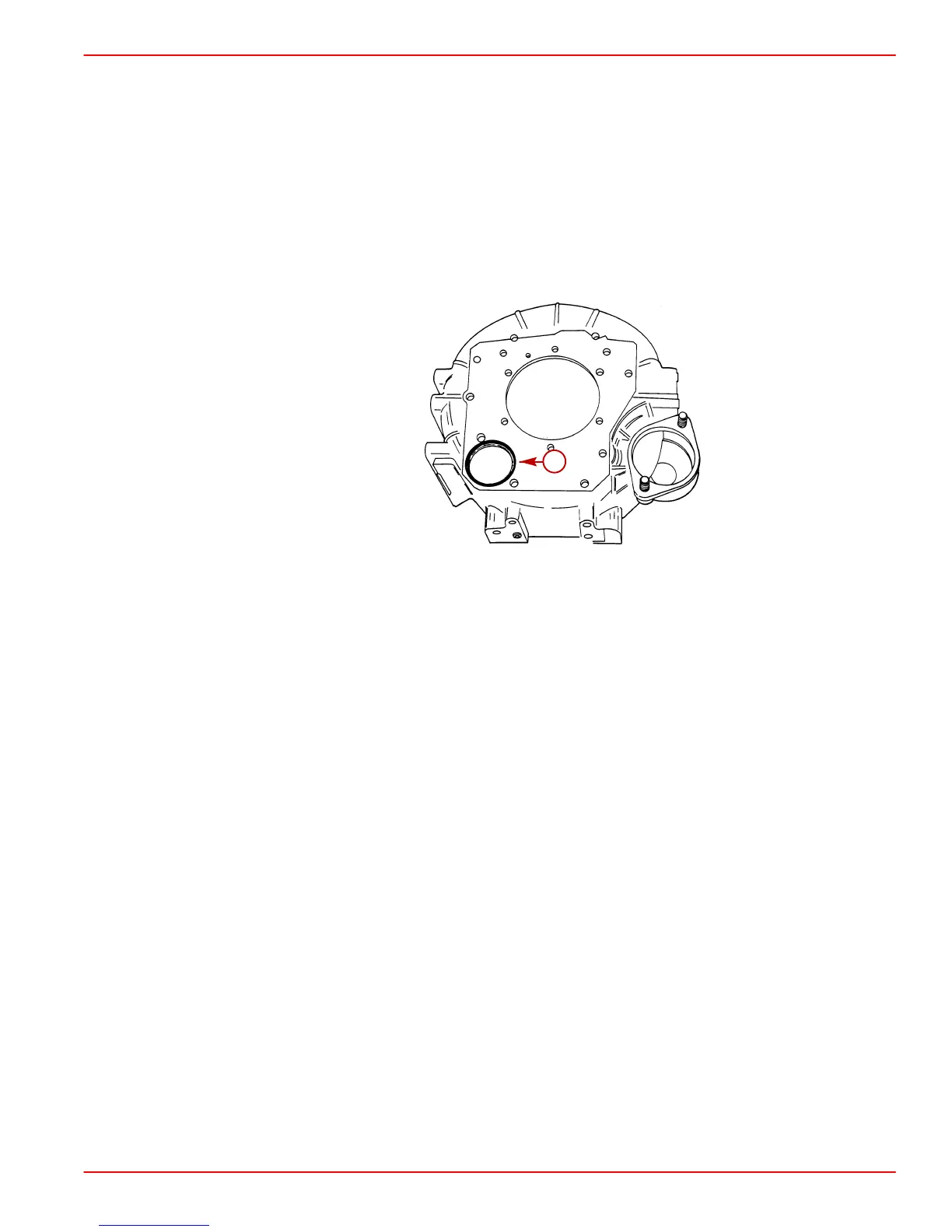

1. Install new O-ring into groove of flywheel housing.

70410

a

a-O-ring

IMPORTANT: Flywheel housing fasteners and hardware must be installed from where

removed.

2. Install flywheel housing. Torque the 9 bolts with washers to 50 Nm (37 lb-ft). Then, torque

the 6 rear main bearing carrier nuts with washers to 27 Nm (20 lb-ft).

IMPORTANT: Flywheel bolts may be used a maximum of 3 times within the prescribed

torque limits.

3. Lubricate threads of flywheel bolts with clean engine oil and install flywheel. Torque bolts

to 110 Nm (81 lb-ft).

4. On Sterndrive (MCM) Models: Install engine coupler. Apply Loctite 271 to threads and

torque bolts to 30 Nm (22 lb-ft).

5. On Inboard (MIE) Models: Install drive plate. Apply Loctite 271 to threads and torque

bolts to 72 Nm (53 lb-ft).

6. Install rear portion of flywheel housing. Torque bolts to 50 Nm (37 lb-ft).

7. Using the screw and wave washer, install and connect the rpm speed sensor.

8. Install the starter and other components previously removed.

Loading...

Loading...