INJECTION PUMP SERVICE MANUAL NUMBER 22

Page 5D-26 90-860074--1 FEBRUARY 2002

CAUTION

Dial gauge indication MUST NOT be allowed to change when mounting nuts are

tightened. Failure to maintain setting will result in engine damage.

8. Torque the three injection pump mounting nuts to 27.5 Nm (20 lb-ft).

9. Remove dial gauge and adaptor. Reinstall fuel injection pump vent screw using new

sealing washer. Tighten securely.

CAUTION

Keep injectors and injection pump pipes and fittings clean. Do NOT allow dirt to

enter fittings when installing. Dirt will cause injectors or injection pump to

malfunction.

CAUTION

Do NOT bend fuel injector pipes. Bending may cause metal to flake off inside

causing injectors or injection pump to malfunction.

10. During Engine Reassembly: Continue engine reassembly. Refer to following

instructions after all other necessary engine reassembly steps are complete.

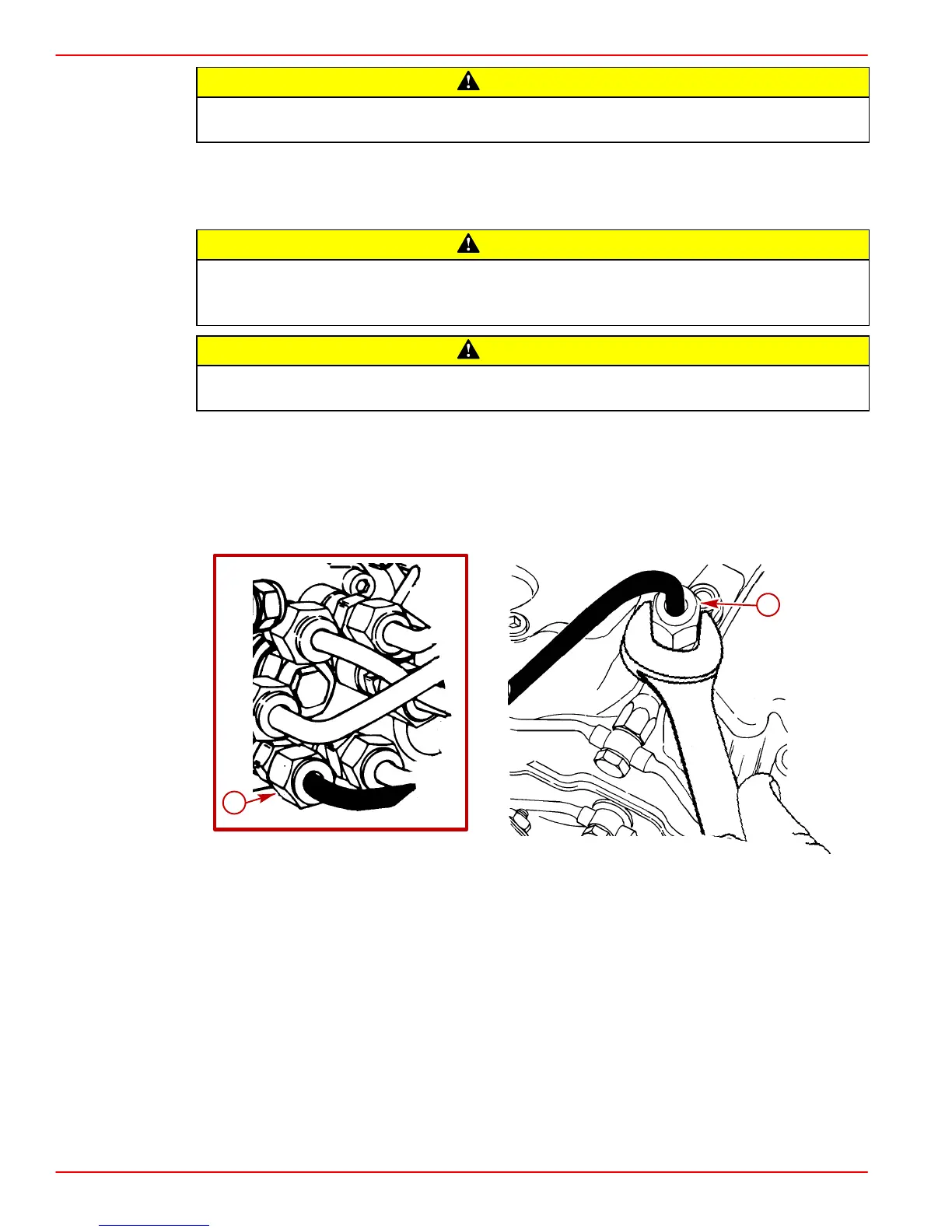

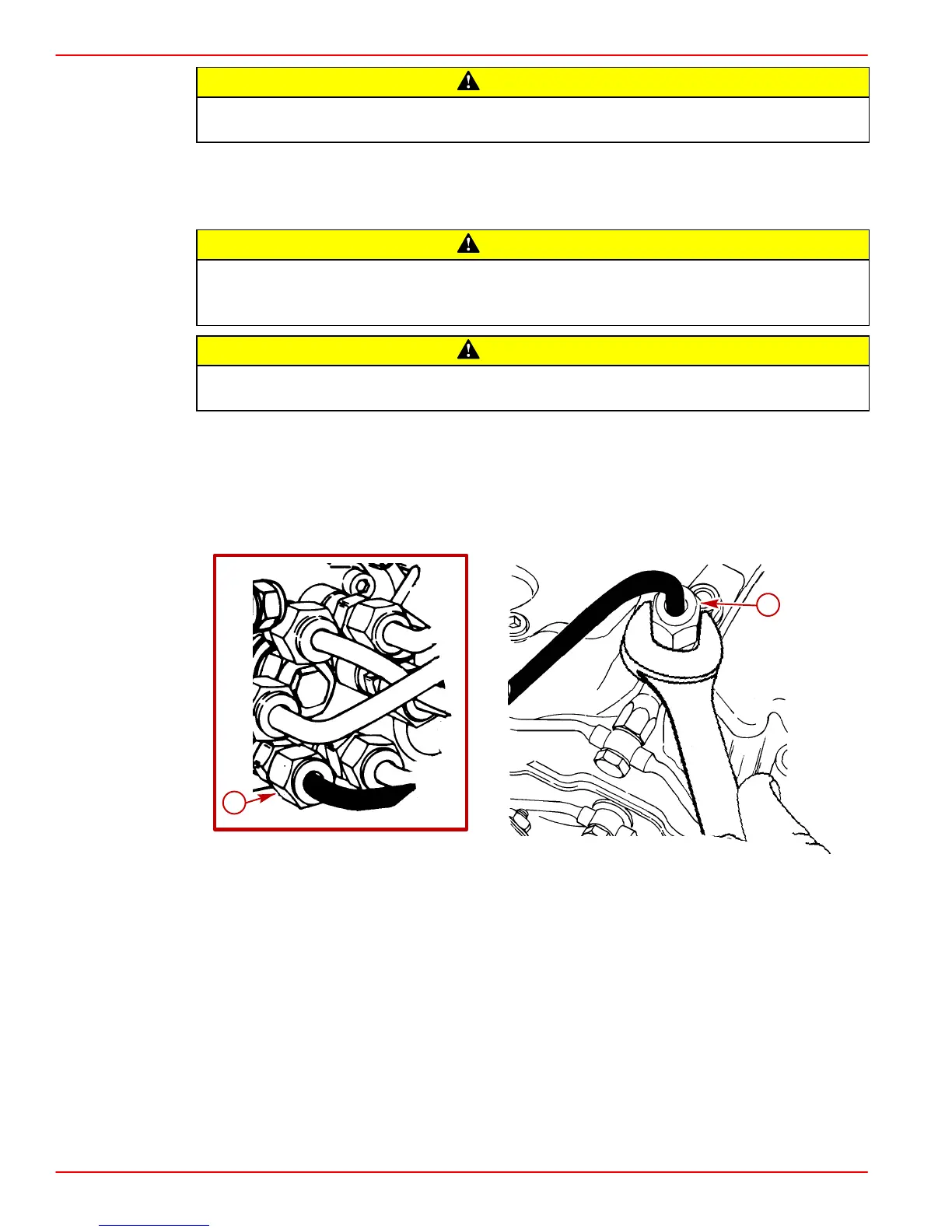

11. With Engine Assembled or After Checking Timing: Install fuel injection pipes on

injection pump and injectors. Tighten all sleeve nuts evenly by hand. Then, torque each

sleeve nut to 18 Nm (156 lb-in.).

17MM

22217

a

75590

b

a-Sleeve Nut At Injection Pump

b-Sleeve Nut At Injector

Loading...

Loading...