INJECTION PUMP

SERVICE MANUAL NUMBER 22

90-860074--1 FEBRUARY 2002 Page 5D-31

13. Check for fuel leaks at injection pump and injectors using a piece of paper placed near

the suspect fitting or sleeve nut to be checked. The paper should show leaks if present.

Do NOT use your fingers to feel for leaks! Watch for fuel spray on paper. Repair as

needed.

14. Retest until certain no leaks are present.

NOTE: Be certain to observe precautions about the use of safety glasses! It is sometimes

helpful to use compressed air to dry the area near fitting and sleeve nuts when checking for

fuel leaks.

15. Allow engine to reach operating temperature. Once again check for leaks as previously

outlined and correct as needed.

WARNING

Dispose of fuel soaked rags, paper, etc. in an appropriate air tight, fire retardant

container. Fuel soaked items may spontaneously ignite and result in a fire hazard

which could cause serious bodily injury or death.

WARNING

Make sure no fuel leaks exist, before closing engine hatch.

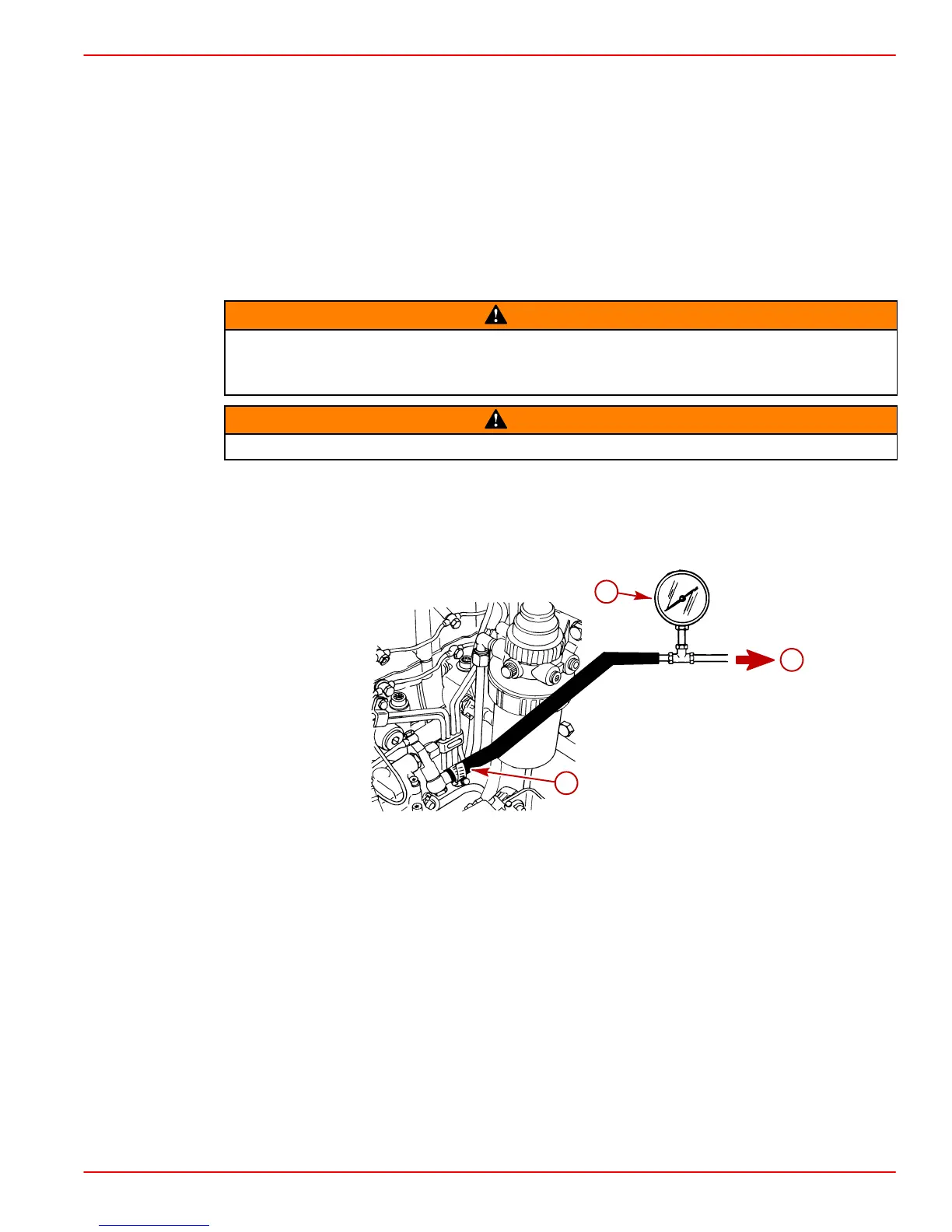

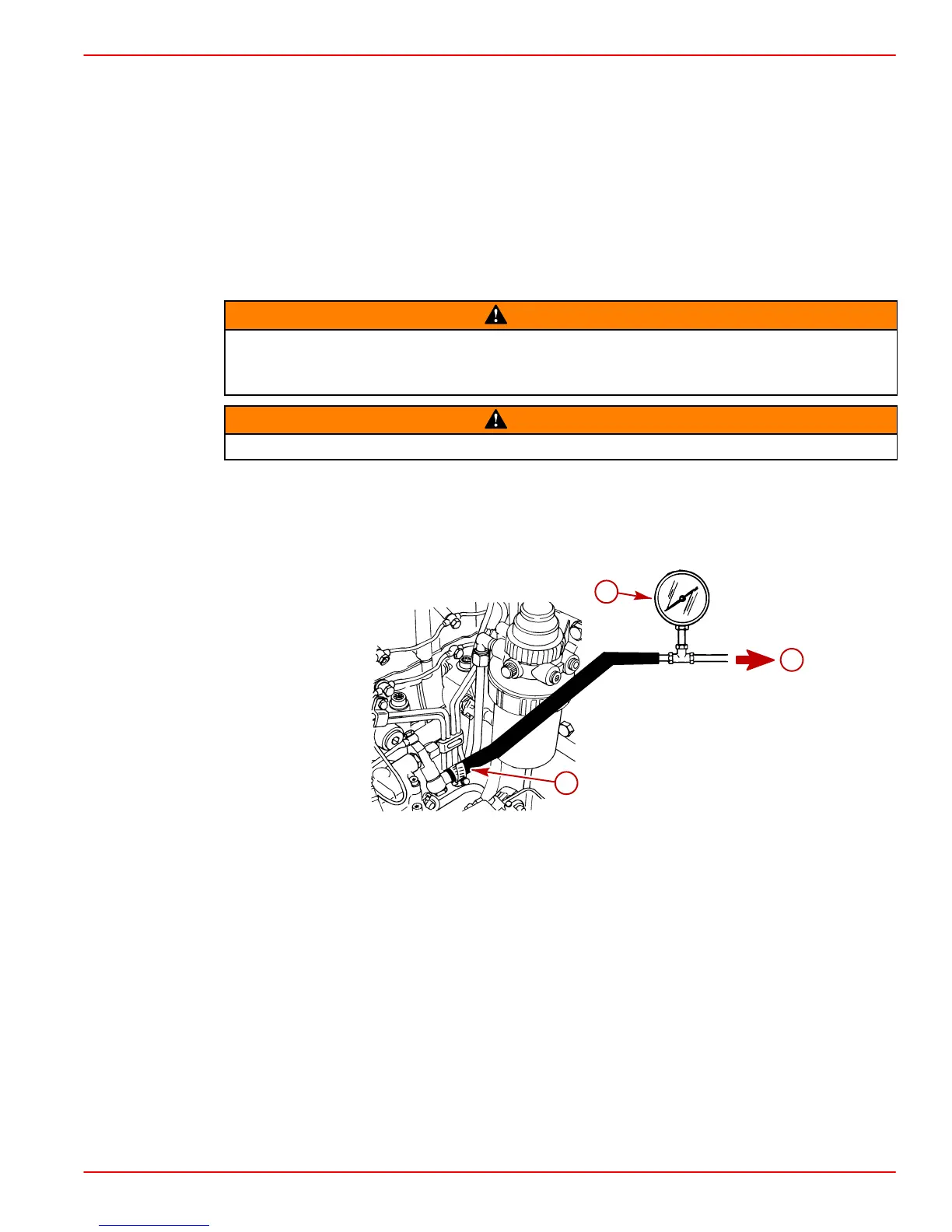

TESTING FUEL RETURN PRESSURE

1. Install a suitable 0-100 kPa (0-15 PSI) pressure gauge in the fuel return hose.

2. If measured value is greater than specified, repair as needed.

75579

a

b

c

71967

Testing Return Pressure

a-Suitable Pressure Gauge

b-Fuel Return Hose

c-Fuel Return To Fuel Tank

Loading...

Loading...