EDI DIAGNOSIS

SERVICE MANUAL NUMBER 22

90-860074--1 FEBRUARY 2002 Page 5E-31

TEST DESCRIPTION:

Verify continuity between the following pins:

ECM 68 PIN CONNECTOR

4 TERMINAL CONNECTOR AT MAP

55 1

64 2

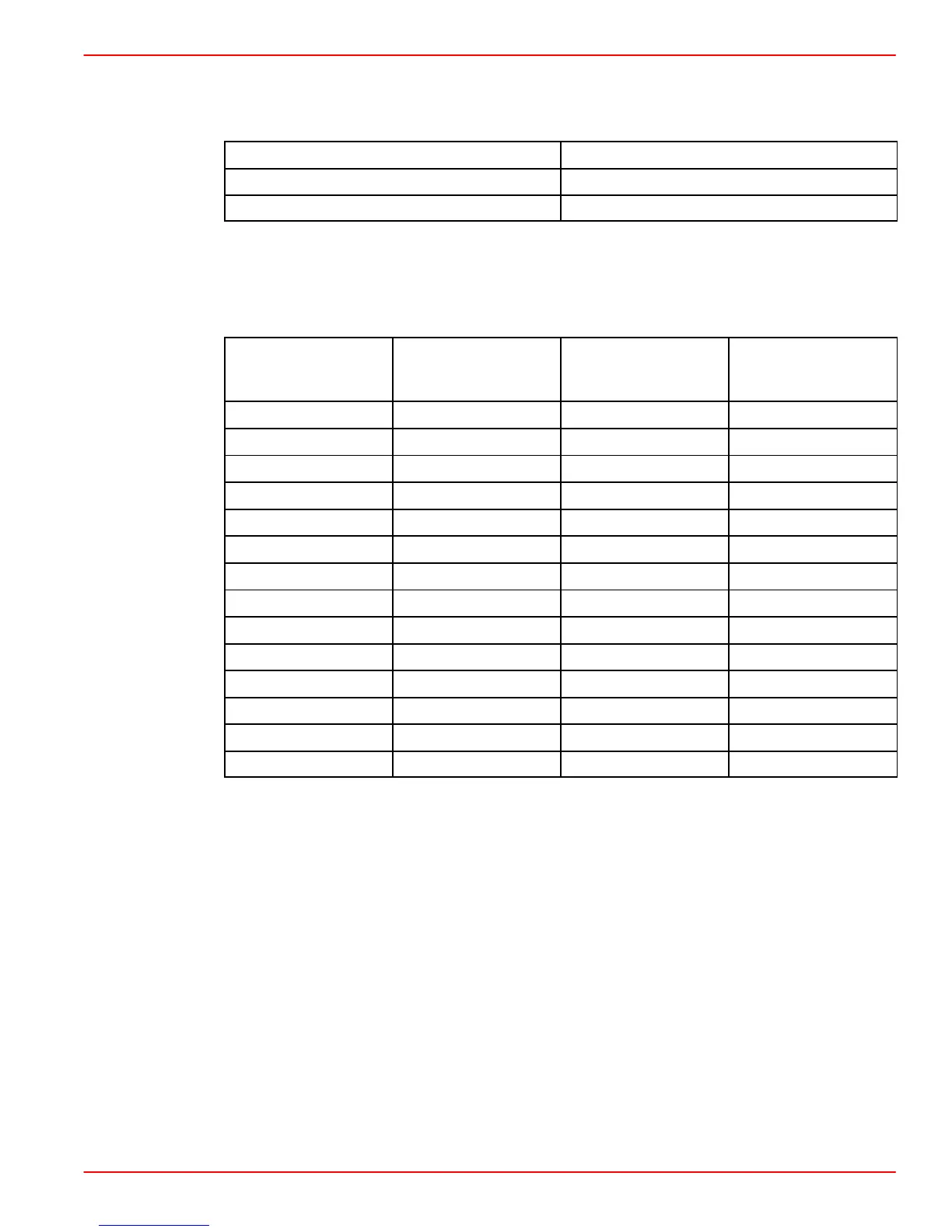

Verify the sensor resistance between the two IAT sensor terminals as a function of

temperature:

NOTE: Stabilization time before each measurement should be at least 10 minutes in test

medium.

TEMPERATURE

°F (°C)

MINIMUM RESIS-

TANCE

(kOhm)

TYPICAL RESIS-

TANCE

(kOhm)

MAXIMUM RESIS-

TANCE (kOhm)

–40 (–40) 1 39.18 48.55 57.92

–30 (–23) 1 22.22 27.00 31.78

–20 (–5) 1 13.24 15.67 18.10

–10 (14) 1 8.160 9.45 10.74

0 (32) 1 5.180 5.89 6.60

10 (50) 1 3.390 3.79 4.190

20 (67) 1 2.270 2.500 2.730

30 (85) 1 1.528 1.692 1.856

40 (104) 1 1.059 1.170 1.281

50 (122) 1 0.748 0.826 0.904

60 (140) 1 0.538 0.594 0.650

80 (175) 1 0.2902 0.3224 0.3546

100 (212) 1 0.1641 0.1852 0.2063

120 (247) 1 0.0970 0.1116 0.1262

DIAGNOSTIC HELP:

Verify the following:

• Open or short in the CKT Pin 55 or CKT Pin 64.

• Bent pin at the ECT or ECM.

• Defective ECT or ECM.

IAT failure influences engine performance as follows:

• FUEL QUANTITY ACTUATION: Maximum engine rpm is 90% of the normal

operating range (15% of fuel quantity reduction).

NOTE: Failure of the IAT and MAP sensor at the same time will limit engine performance

to 60% maximum of the normal operating range (50% fuel quantity reduction).

IMPORTANT: Replace the O-ring seal whenever removing the IAT/MAP sensor.

Torque the sensor to specification when replacing.

Loading...

Loading...