MM098-002 – LOGOS ONE – Operator Manual

128

C. Appendix

C.1. HOW TO MANAGE SAMPLES WHILE AN ALARM IS OCCURRING

Never leave samples in open air or under fume hood, to avoid drying.

Put samples as quickly as possible into an external container with one of the following reagent in a quantity

sufficient to cover all samples:

Either Ethanol (90-100%) or Isopropanol

Check the wetness level of at least 10% of samples (in different parts of the rack). If wetness level appears:

GOOD WETNESS WITH NO DOUBTS

A. Let samples in reagent.

B. Check the step when the emergency situation

occurred.

C. Check if the unit can be used for a new cycle

(*).

D. Follow the instructions on how to resume an

interrupted cycle and restart the cycle with

samples using step start procedure.

Select the correct step to start from in the following

table:

NOT GOOD WETNESS

A. Follow the recovery laboratory internal protocols

for air dried samples.

B. If not available, follow Milestone suggested

recovery protocol.

C. Check if the unit can be used for a new cycle

(*).

D. Restart the processing cycle.

(*) If necessary, contact your local customer support

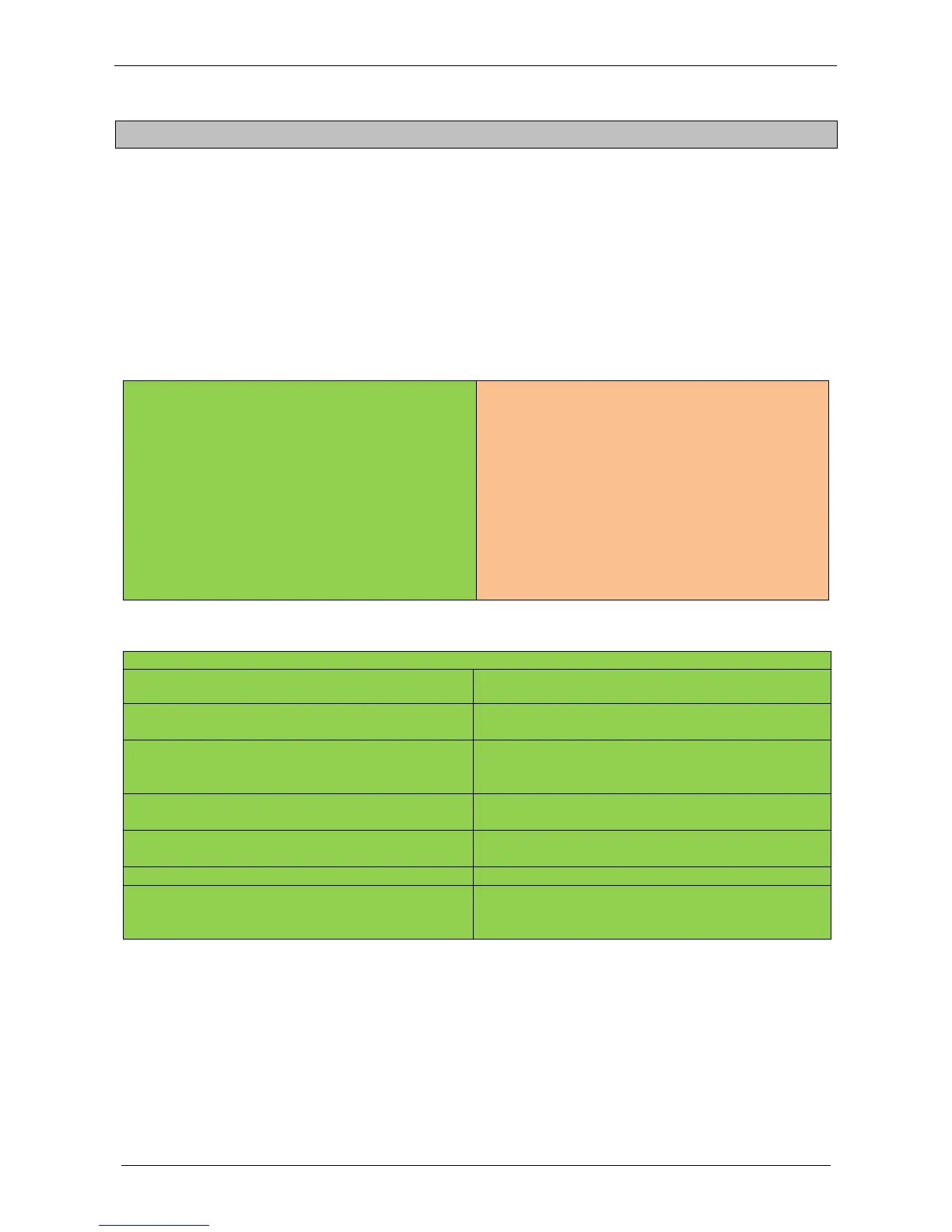

GOOD WETNESS WITH NO DOUBTS

ALARM OCCURRED DURING THE FOLLOWING

PROCESSING STEP

STEP START. RESTART FROM:

LOADING FIXATIVE

FIXATION

Fixation step (fixation uncertain)

UNLOADING FIXATIVE

LOAD/UNLOAD RINSING

RINSING

Rinsing or Ethanol step if at least one rinsing step

has been performed

LOADING ETHANOL

ETHANOL

UNLOADING ETHANOL

ISOPROPANOL

MOVING SAMPLES TO WAX

WAX MOVING TO MAIN CAVITY

WAX IMPREGNATION

Loading...

Loading...