FX Series Programmable Controllers Points Of Technique 10

10-22

FX2N (V2.00 or above) Communications

In the FX2N V2.00 or above and FX2NC, full duplex communication is performed.

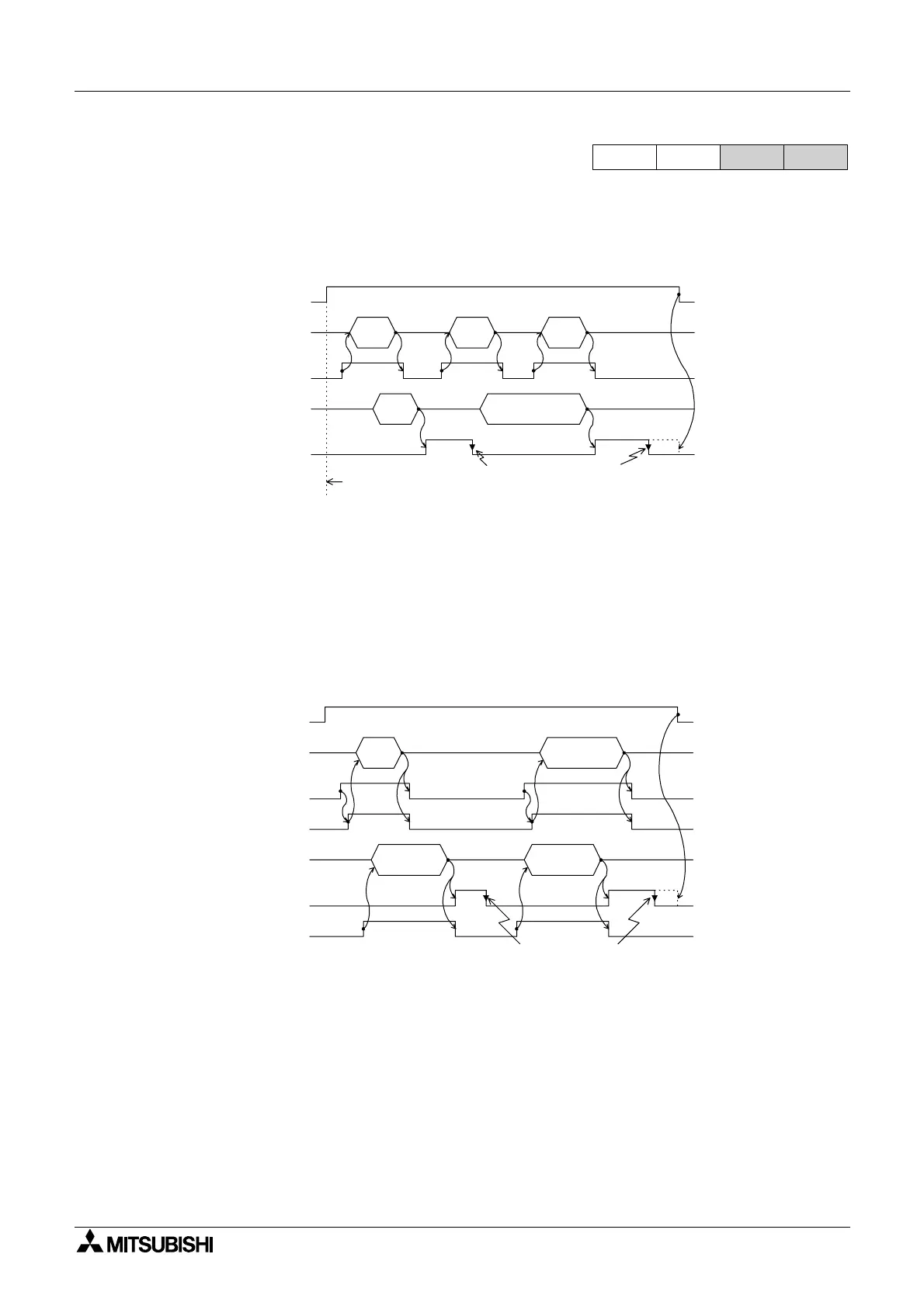

1) No Hardware Handshaking D8120 (B12, b11, b10) = (0,0,0)

2) Terminal Mode

The control line and transmission sequence are identical to those in the FX, on page

3) Normal Mode 1 D8120 (b12, b11, b10) = (0, 1, 1)

FX

1S

FX

1N

FX

2N

FX2NC

Resetitusingaprogram.

When it is not turned off, the

next data cannot be received.

Data 1

RS

instruction

Send data

SD (TXD)

OFF ON

Data 5

OFF

ON

Send request

M8122

Receive

completion

M8123

Data 3

Data 2

Data 4

OFF

ON

ON

The receive wait

status is started

Receive data

RD (RXD)

Reset using a program.

When it is not turned off, the

next data cannot be received.

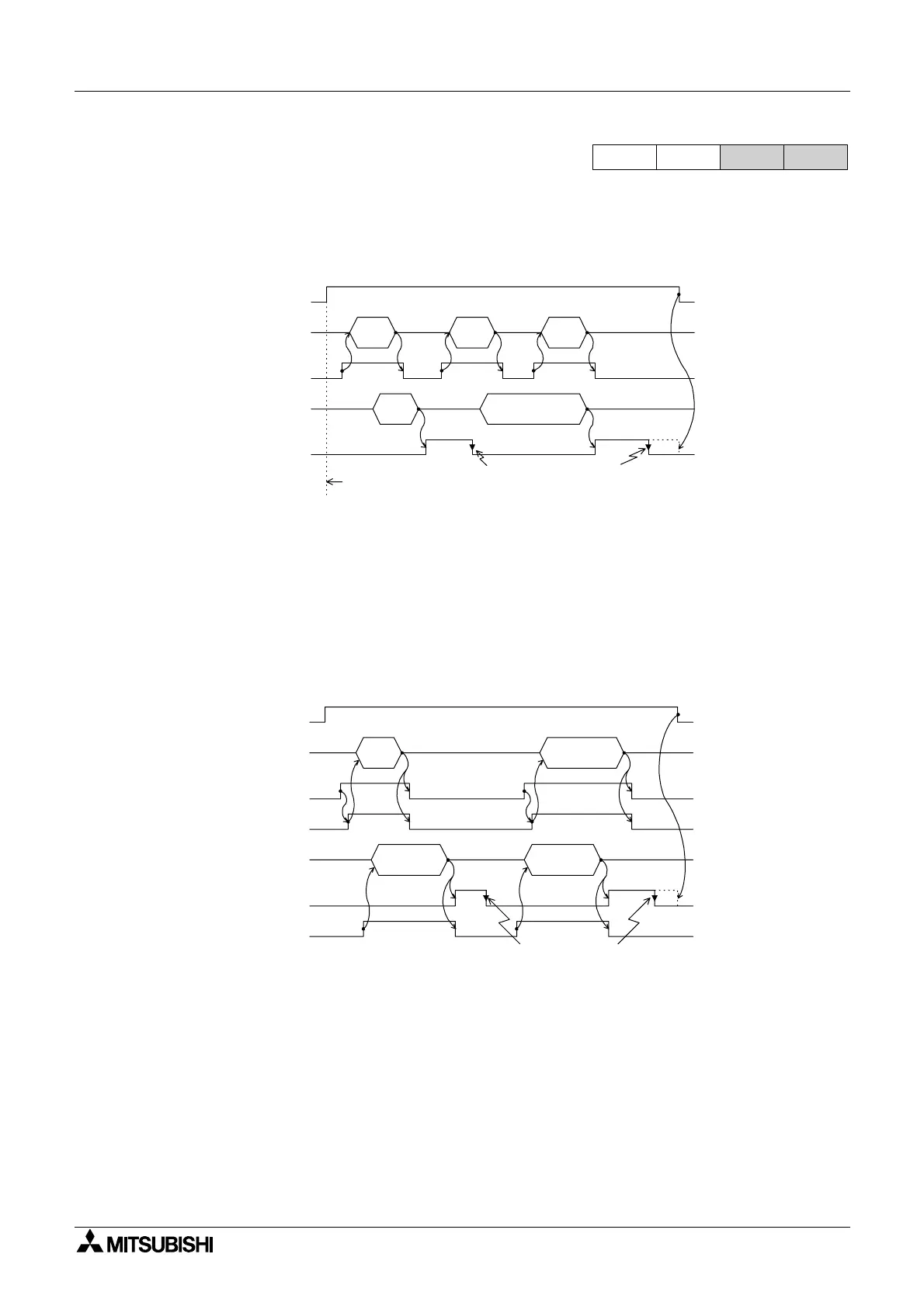

Data 1

OFF

OFF ON

ON

Data 4

OFF ON

RS

instruction

Send data

SD (TXD)

ER(DTR)

ON

Receive

completion

M8123

OFF ON

Data 2 Data 3

Receive data

RD (RXD)

OFF ON

Send request

M8122

DR(DSR)

Loading...

Loading...