68 / 155

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

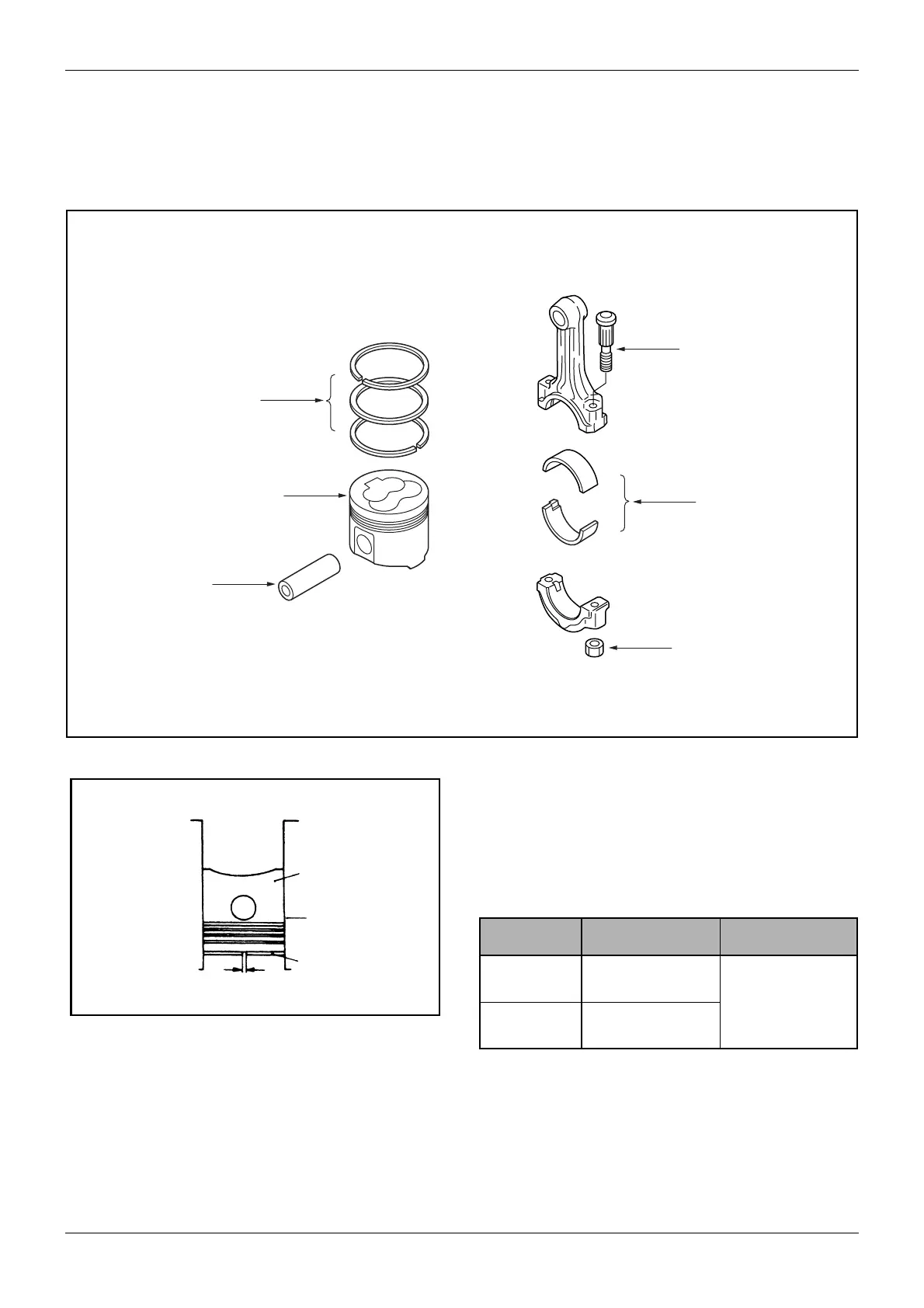

PISTON AND CONNECTION ROD ENGINE MAIN PARTS

15.3 Inspection

Inspect the removed parts. If any parts are found

defective, replace or repair them.

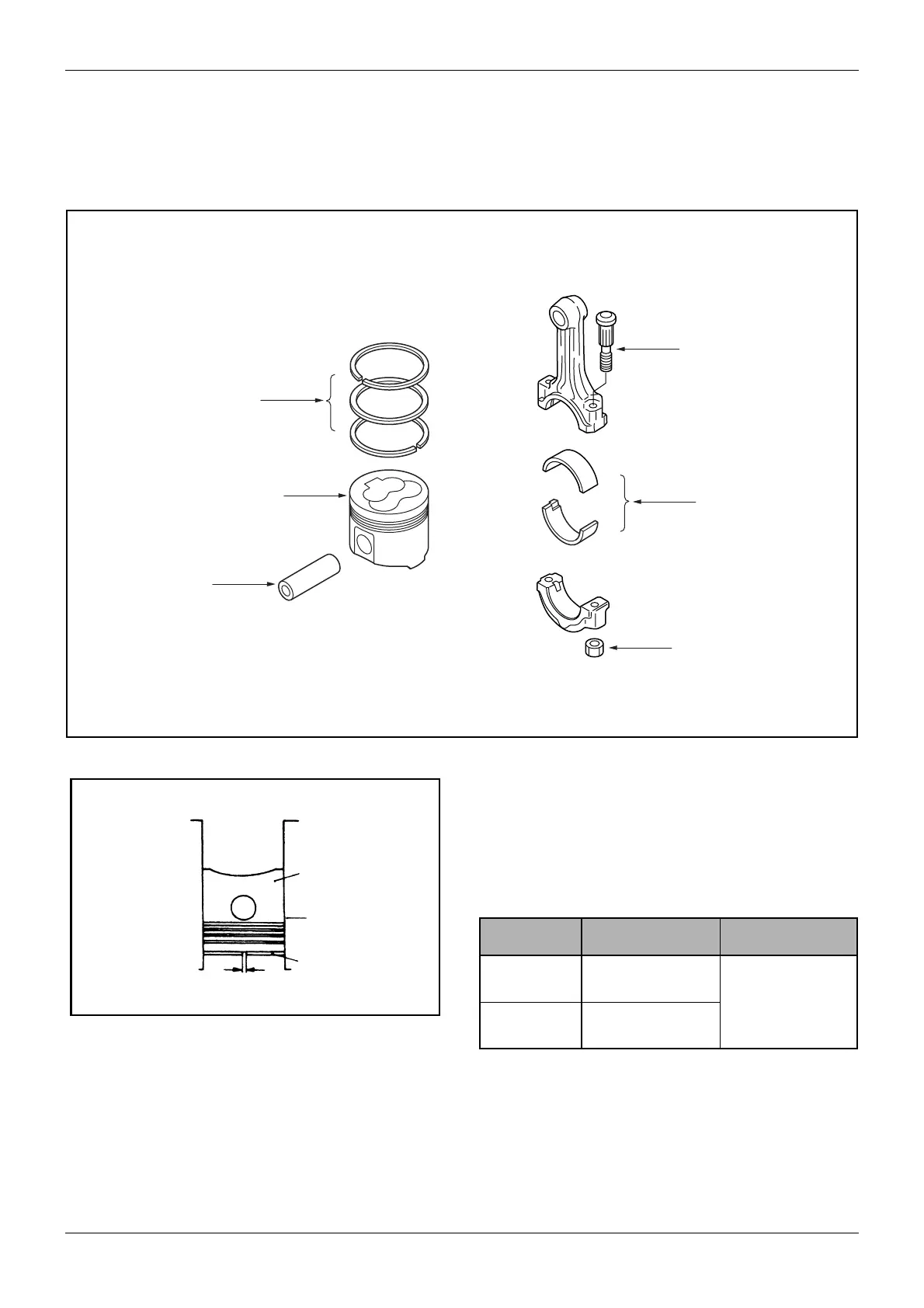

15.3.1 Inspection of piston ring gaps

Place each piston ring into the cylinder bore and push

the ring with piston to have square position to the

cylinder wall. Measure the ring gap with feeler gages. If

the measurement exceeds service limits, replace that

piston ring.

Damage, wear, and ring gap

Journal bearing-

wear and damage

• Bend and twist

• Big end play.

Standard: 0.1 to 0.35

mm [0.0039 to 0.0138

in.]

Damage

• Contact and seizure

• Flaking and fusion

• Oil clearance.

Standard: 0.028 to

0.071 mm [0.0011 to

0.0028 in.]

Damage and wear

• Wear, seizure and

streaks

• Clearance between

piston and cylinder.

Standard: 0.07 to

0.115 mm [0.0028 to

0.0045 in.]

• Wear of piston ring

grooves

Damage, wear,

and ring gap

Figure 69 Inspection of piston and connecting rod

Figure 70 Measuring ring gap

Piston

Cylinder

Ring

Ring gaps

Ring Standard Service Limit

No. 1

No. 2

0.15 to 0.30

[0.0059 to 0.0118]

1.5 [0.059]

Oil 0.15 to 0.35

[0.0059 to 0.0138]

Table 27 Inspection of camshafts, unit in mm [in.]

Loading...

Loading...