94 / 155

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

INJECTION NOZZLE FUEL SYSTEM

22.4 Inspection

Never attempt to disassemble the pump unless it is

necessary.If the pump is assumed defective, it is

recommended to replace the pump assembly.

22.5 Assembly

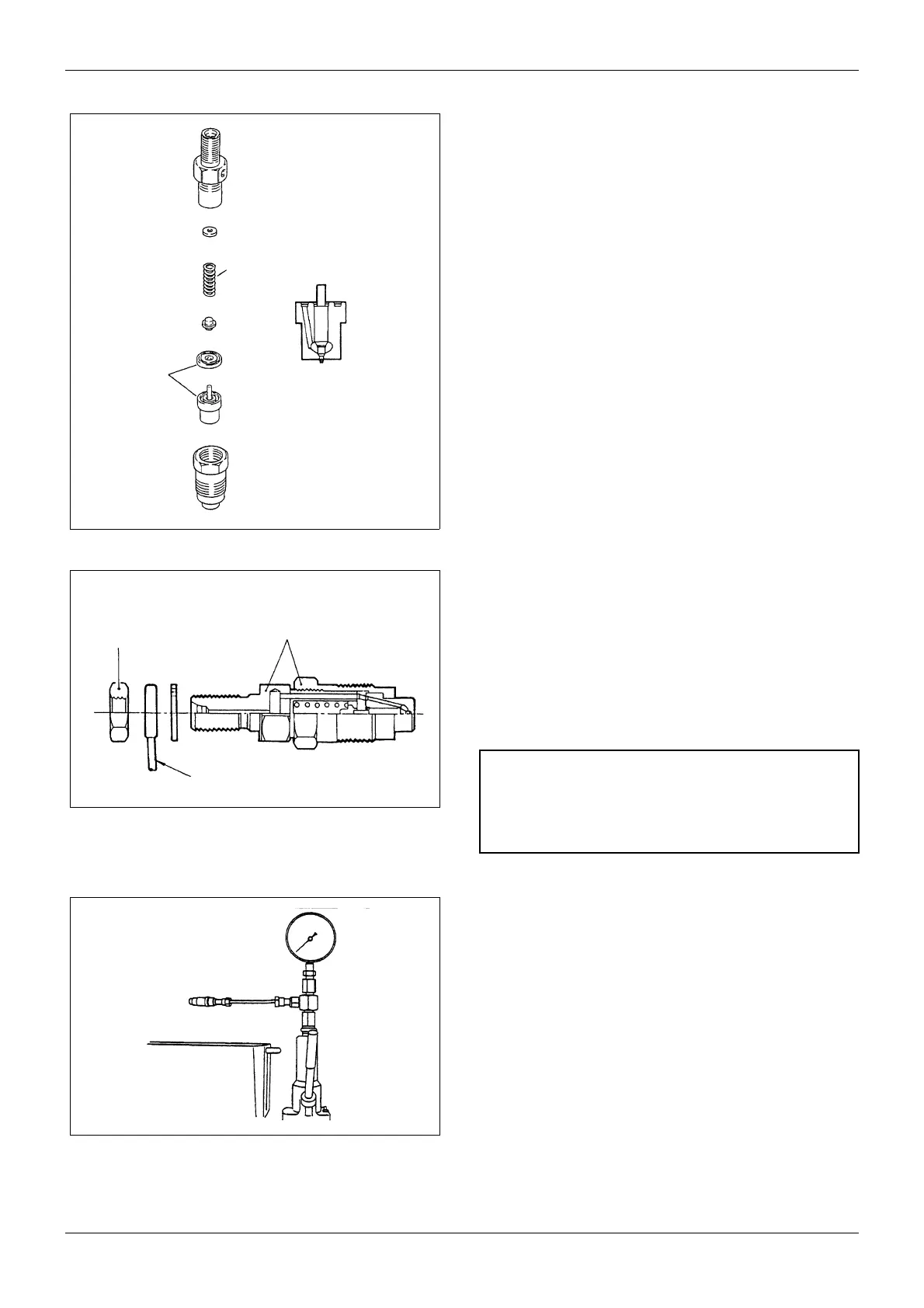

1. Insert the nozzle assembly into the retaining nut so

that the nozzle is correctly seated in the nut.

2. Place the distance piece, retaining pin, pressure

spring and shim washer on the nozzle tip.

3. Tighten the nozzle holder body fully by hand

4. Grip the nozzle holder in a vise. Tighten the

retaining nut to the specified torque.

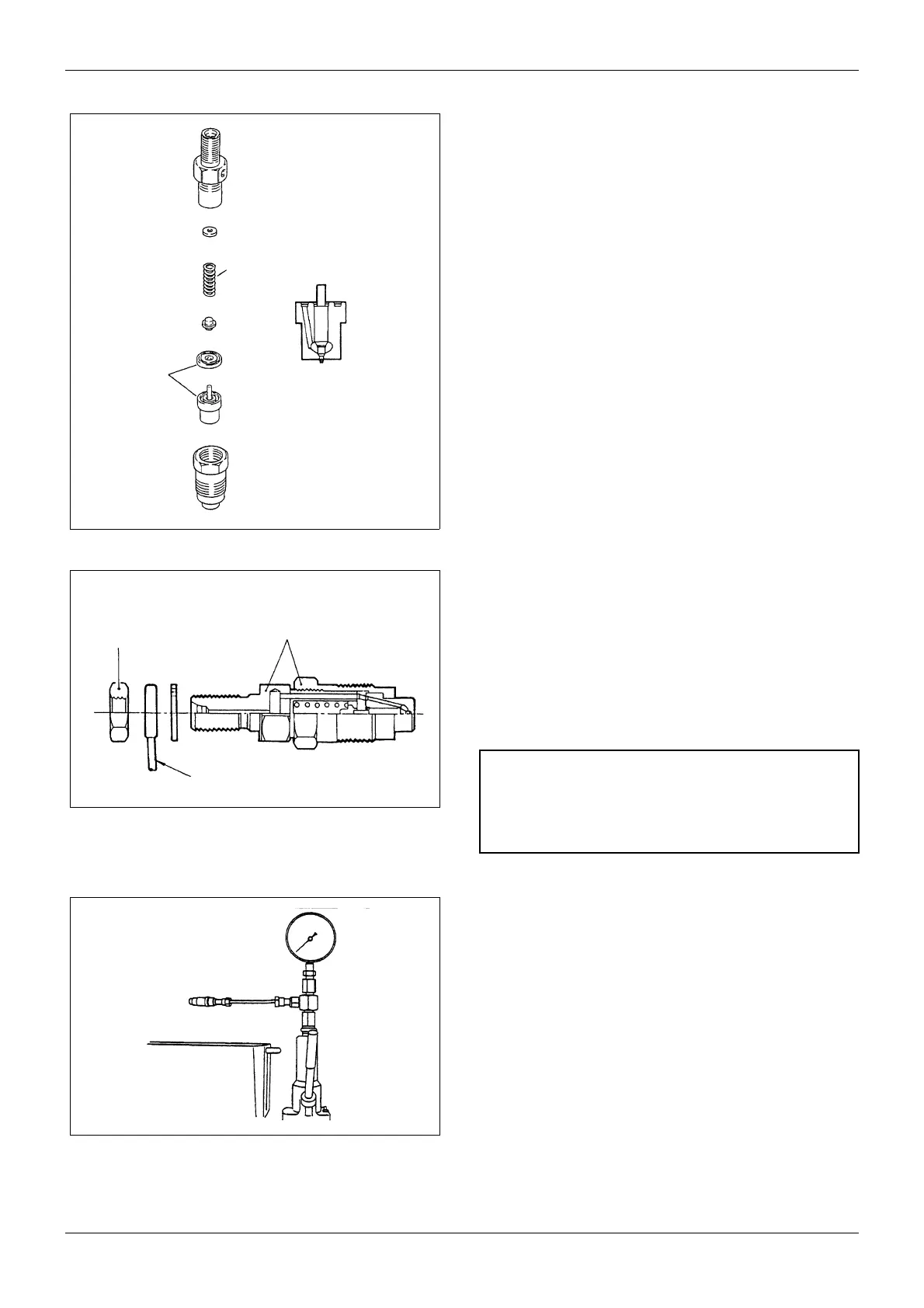

22.6 Adjustment

Adjust injection starting pressure by increasing or

decreasing the thickness of inserting shim washer.

Varying shim thickness by 0.1 mm [0.0039 in.] causes

injection start pressure to change 0.98 MPa

(10 kgf/

cm

2) [142.3 psi].

Available shims:

10 kinds of shims available from 1.25 mm to 1.7 mm

[0.0492 to 0.0669 in.] in thickness, in increment of 0.05

mm [0.0020 in.].

Figure 98 Inspecting nozzle

Wear

Fatigue and break

Poor contact

Deformation

and break

While immersed in

kerosene, check for

smooth sliding.

Figure 99 Assembling the nozzle

Tightening torque:

34.3 to 39.2 N·m

(3.5 to 4.0 kgf·m)

[25.32 to 28.93 lbf·ft]

Tightening torque:

24.5 to 29.4 N·m

(2.5 to 3.0 kgf·m)

[18.08 to 21.70 lbf·ft]

Return pipe

CAUTION

If required, always replace the nozzle as a complete

assy.

Figure 100 Testing nozzle

Loading...

Loading...