79 / 155

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

CYLINDER BLOCK

ENGLISH

ENGINE MAIN PARTS

17.2 Inspection

Inspect the cylinder block. If it is found defective, repair

or replace the block.

17.3 Reboring of cylinder

When reboring a cylinder, use the following procedure :

1. Selecting a piston

Piston service size

0.25 OS or 0.50 OS

2. Measuring the piston diameter

3. Reboring finish dimension =

[Piston OD] + [Clearance] –

[Honing allowance (0.02 mm [0.00079 in.])]

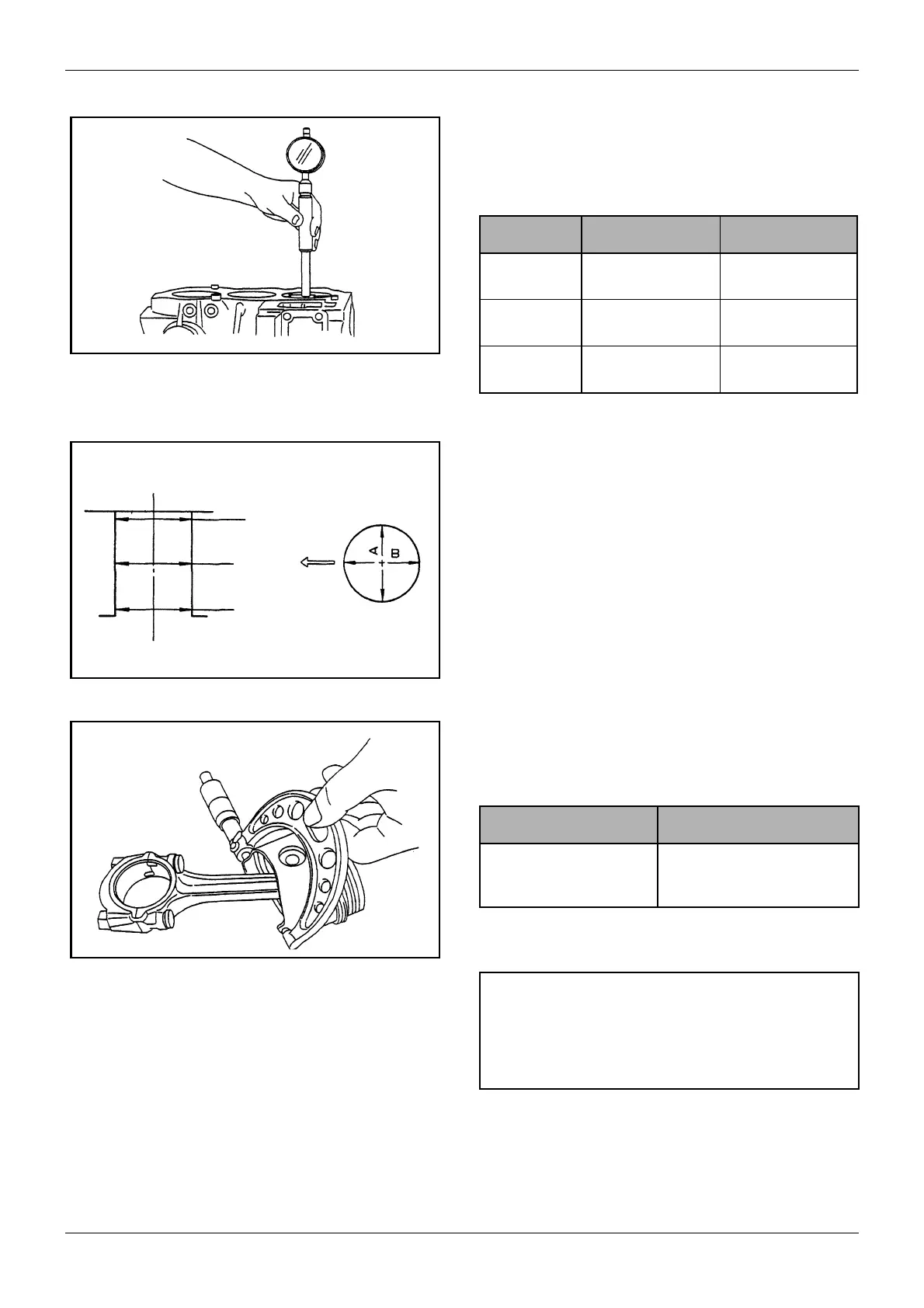

Figure 84 Measuring cylinder bore

Model Standard Service limit

L2A, L3A

65

[2.5591 ]

+0.7

[+0.0276]

L2C, L3C

70

[2.7559 ]

+0.7

[+0.0276]

L2E, L3E

76

[2.9921 ]

+0.7

[+0.0276]

Table 35 Cylinder bore (mm [in.])

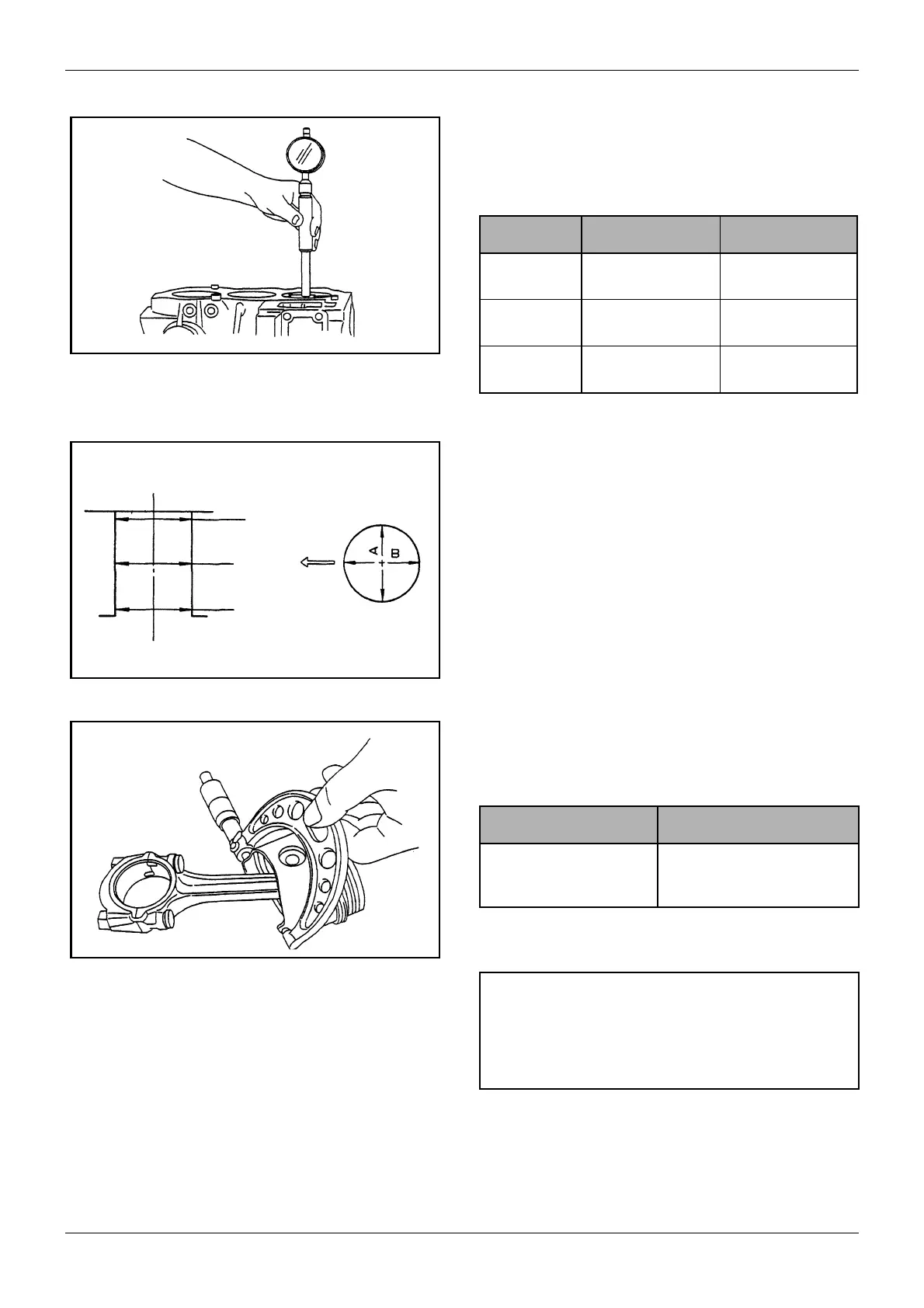

Figure 85 Cylinder bore measuring positions

Approx. 10 mm [0.40 in.]

from upper end

Front

Direction of measuring

Measuring position

Center

Lower

Figure 86 Measuring piston diameter

Description Standard

Clearance

(between piston and

cylinder)

0.071 to 0.084

[0.00280 to 0.00331]

(A to D)

Table 36 Oil clearance (mm [in.])

CAUTION

When it is necessary for a cylinder to be rebored to

the next over size, other cylinders must also be

rebored to the same over size.

+0.03

0

+0.03

0

+0.03

0

+0.0012

0

+0.0012

0

+0.0012

0

Loading...

Loading...