SHOP MANUAL MT26/31 - 12.2004SHOP MANUAL MT26/31 - 12.2004

GENERAL

CH 0 PAGE 18 CH 0 PAGE 19

GENERAL

SHOP MANUAL MT26/31 - 12.2004SHOP MANUAL MT26/31 - 12.2004

GENERAL

CH 0 PAGE 18 CH 0 PAGE 19

GENERAL

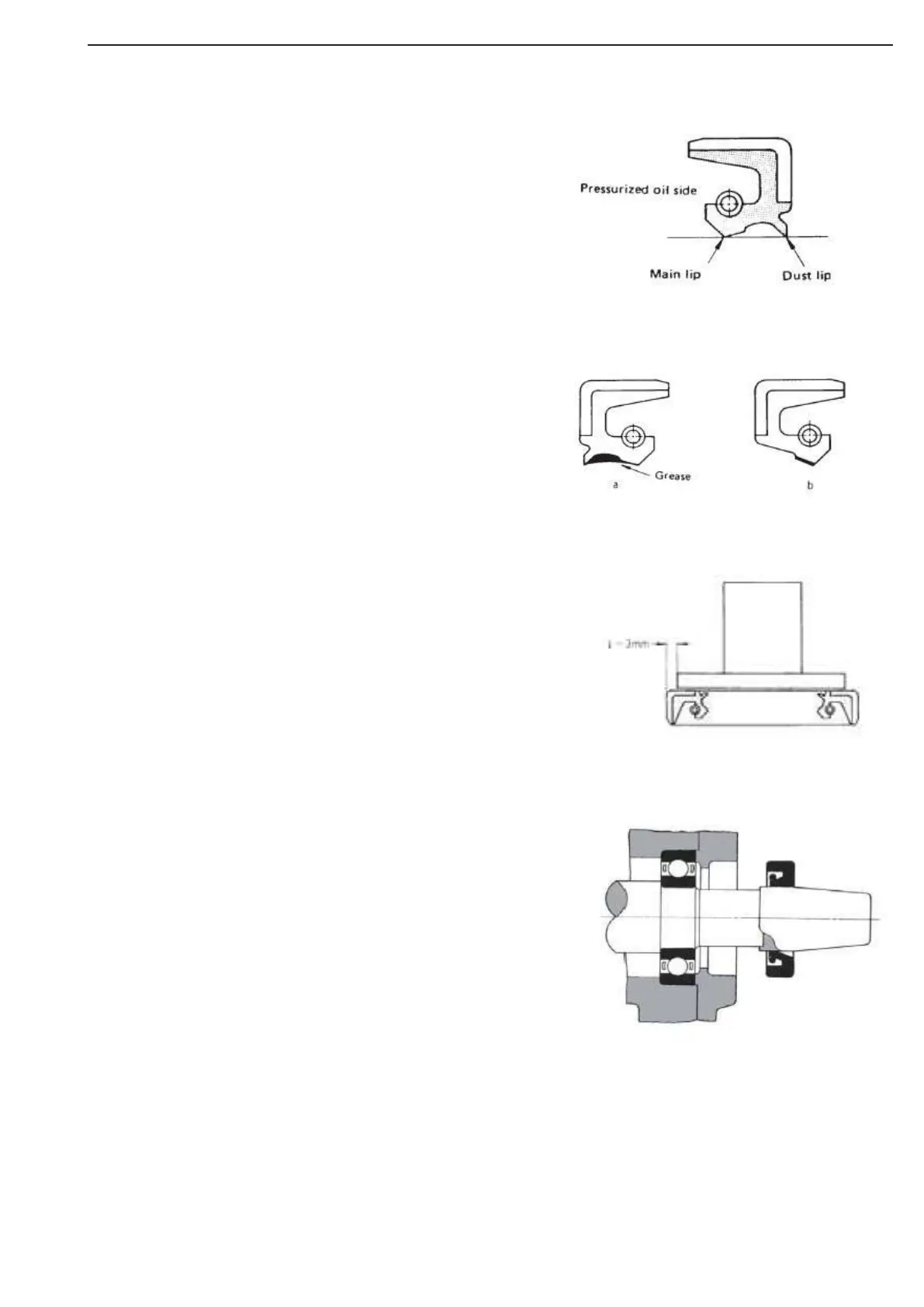

Be careful to install an oil seal with its lips in the

right direction as shown below.

Before installing an oil seal, coat it with grease

to prevent dry-friction, which may occur during the break-in

operation of the machine, according

to the following procedure:

a) In case of a double-lip type, uniformly coat the surface of

the groove around the lip with grease.

b) In case of a single-lip type, uniformly and evenly coat the

surface surrounding the lip on the opposite side of the sealing

surface of lip.

Apply the lube oil or grease to the surface an

chamfered edge of the shaft on which the oil

seal is to be installed, so that the shaft may b

smoothly inserted into the oil seal without

pinching the lip and that a proper lubrication of

the shaft during the break-in period of the

machine is accomplished.

Be sure to apply grease only by the fingers. Restrict the

amount of grease to be applied in the range of 40 to 60 per-

cent of the vacancy formed between the lips.

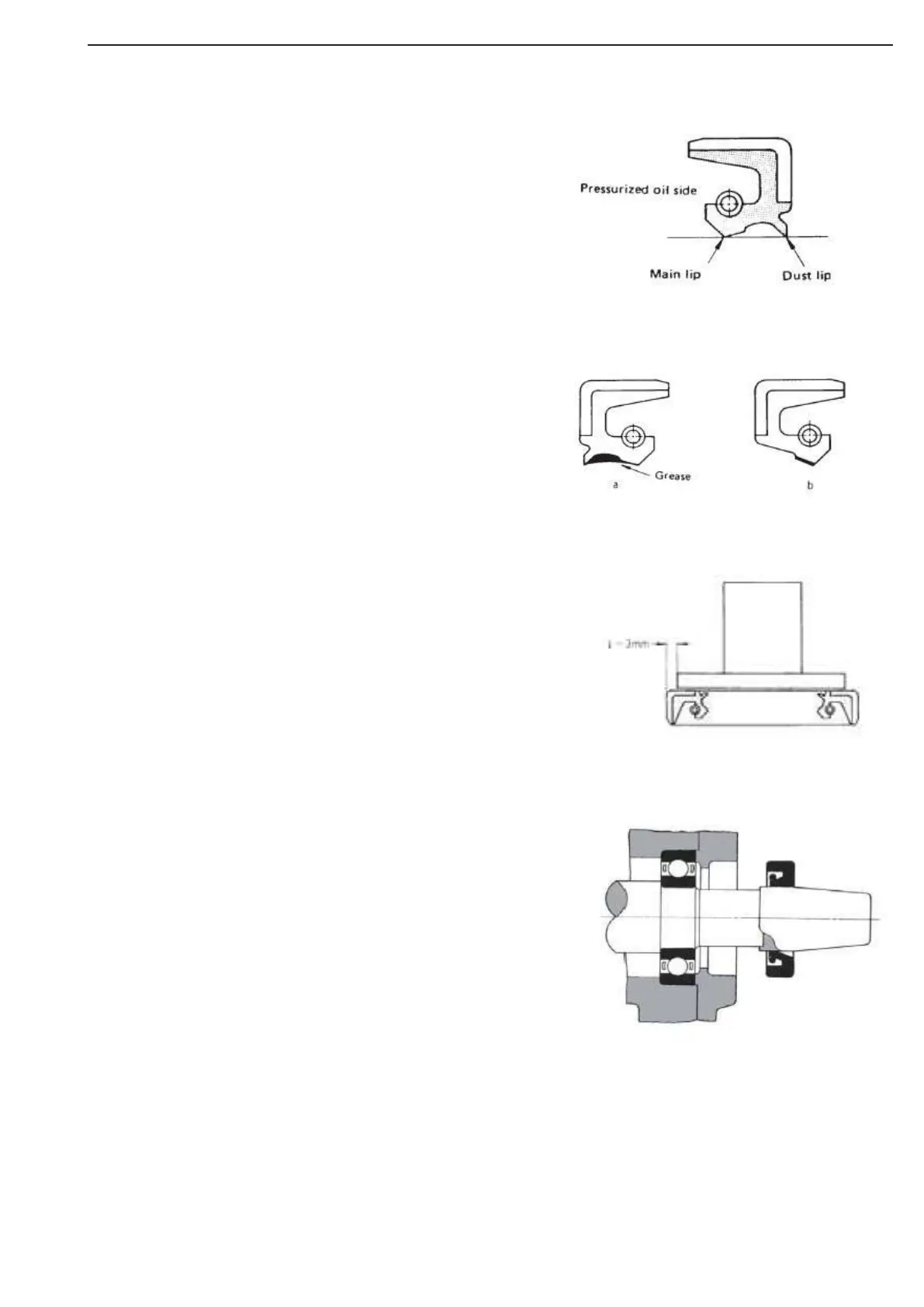

When fitting an oil seal, use of a guide shown below is recom-

mended to prevent the lips of the oil seal from being scratched

or soiled with dust.

Make sure that there are no scratches and dust on the contact

surface (with the shaft) of an oil seal.

Do not use any hydraulic press to fit press-fit an oil seal.

Use only a hand press and a jig. The jig should be a snap

cylinder of 1 to 3 mm smaller in the outer diameter than the

oil seal, and the press-fit surface of the oil seal should be free

from scratches and deformation.

When installed, the oil seal should not be inclined at an angle.

Press-fitted angle of an oil seal should not exceed the per-

missable limit of 0.2 mm/100 mm diameter.

Discard copper gaskets whenever they are disassembled.

Immerse leather gaskets in oil before assembly.

Coat liquid gasket compound to the specially designated

gaskets and o-rings (specified in each step). Make sure that

the surface to be coated with liquid gasket is free from large

scratches or any other damage. Wipe off dust, paint or oil, if

any, from the surfaces to be coated with liquid gasket.

Uniformly apply liquid gasket to the contact surface, and wait

for a few minutes to allow drying of the gasket. When the

liquid gasket becomes dry enough for the finger touch, put the

gasket or o-ring in place.

0.2.20 Handling of Oil Seals

0.2.21 Handling of Gaskets

Loading...

Loading...