Subject to modifications

User Manual

Operation Instructions

2.1A-30008-A04

Page 45 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Technical Data, continuation

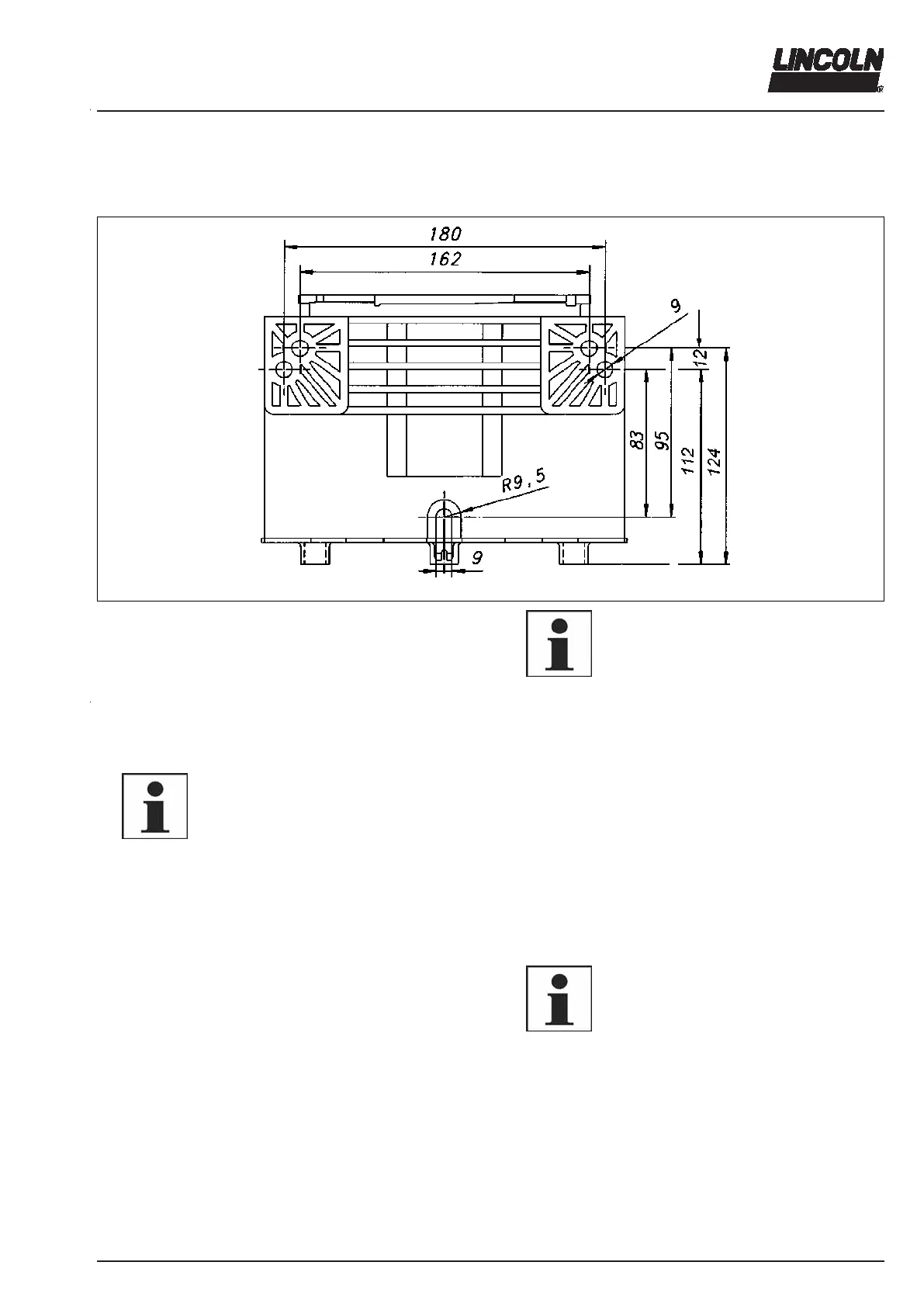

Attaching boreholes of the 2 l, 4 l and 8 l pump

1171b03

Fig. 55 Attaching boreholes of the 2 l, 4 l and 8 l pump

6001a02

NOTE

Tighten pump models with 2 l-flat-type, 4 l

and 8 l reservoir with three fastening

screws (see point R 9,5).

Lubricants

6001a02

IMPORTANT

Absolute cleanness is essential when

handling lubricants. Impurities will remain

suspended in the lubricant and cannot

settle. This will result in damage to the

lubrication system and thus to the bear-

ing.

The Quicklub pump can dispense commercial greases up to

NLGI grade 2 or mineral oils of at least 40 mm/s (cST) at

40 °C.

The proven lubricants (see following tables) have been

tested by us with regard to their transportability and bleeding

behavior. We can recommend them for an application up to

the indicated minimum delivery temperature in Quicklub

lubrication systems by Lincoln& Co. KG. During the tests

these lubricants did not cause any damage due to incompati-

bility with the material used by us. The composition of the

lubricants, their behavior during the transport and their com-

patibility with other material are not known to us.

The lubricants we recommend on the basis of the manufac-

turer’s data sheet (see following tables) can be used in our

lubrication systems up to the indicated minimum delivery

temperature.

Lubricant recipes may change. In case of doubt, send your

request for more information to the manufacturer of the cen-

tralized lubrication system. This refers in particular to lubri-

cants with more than 3% graphite that are transportable in

lubrication systems only conditionally.

The lubricants released by us have not been tested with re-

gard to their long-term behavior.

6001a02

IMPORTANT

The manufacturer of the centralized

lubrication system can accept no liability

for:

- damages due to the use of greases that

are not or only conditionally transport-

able in centralized lubrication systems.

- damages on parts of the centralized

lubrication system caused by chemical

or biological changes of the lubricant

used.

- damages due to the incompatibility with

other materials.

The liability is limited to transportable

lubricants in centralized lubrication sys-

tems.

Loading...

Loading...