Subject to modifications

User Manual

Operation Instructions

2.1A-30008-A04

Page 9 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Description

4355a01

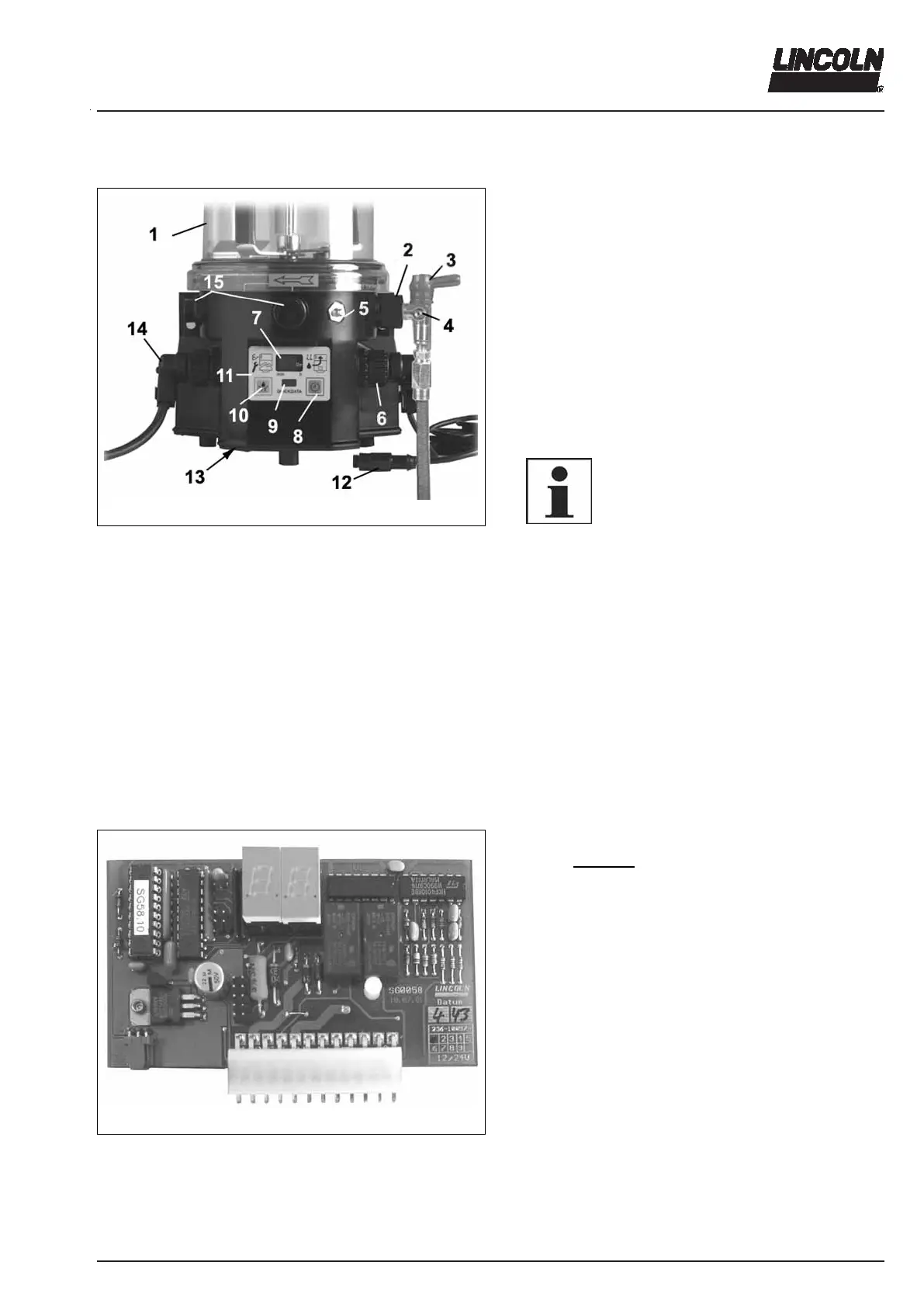

Fig. 2 Components of pump 223, 233

1 - Reservoir

2 - Pump element

3 - Pressure relief valve

4 - Filling nipple, system

emergency lubrication

possible

5 - Fillilng nipple, pump

6 - Adaptor for piston detec-

tor

7 - Display

8 - Momentary-contact

switch for indication or

setting of pause time

9 - Reading window for Datalog-

ger (only P233)

10 - Momentary-contact switch for

additional lubrication

11 - Membrane key pad

12 - Piston detector

13 - Covering to the p.c.b.

14 - Adaptor for power supply

15 - Closure plug for the use of a

pump element

Quicklub centralized lubrication pumps

Are compact multi-line pumps consisting of the following

components:

- Housing with integrated motor

- Reservoir with stirring paddle and fixed paddle

- P223: Control printed circuit board (p.c.b.)

P233: Data logger (control p.c.b. with readable

data memory)

- Pump element

- Accessories:

- Pressure relief valve

- Refilling unit

- Electrical connection parts

6001a02

NOTE

Pressure relief valve are not part of the

pump components and have to be or-

dered separately. Accessories for refilling

of the reservoir (see parts catalogue).

can drive up to 3 pump elements

operate according to lubrication cycles (pause and operat-

ing times)

can be equipped with a low-level control

can supply up to 100 lubrication points depending on the

line lengths

are designed for the automatic lubrication of the con-

nected lubrication points

are designed for the delivery of greases up to NLGI 2 at

temperatures from - 25° C to 70° C

can be used at low temperatures down to - 40° C

During the operating time the pump dispenses lubricant to the

connected lubrication points via one or several metering de-

vices.

6288b04

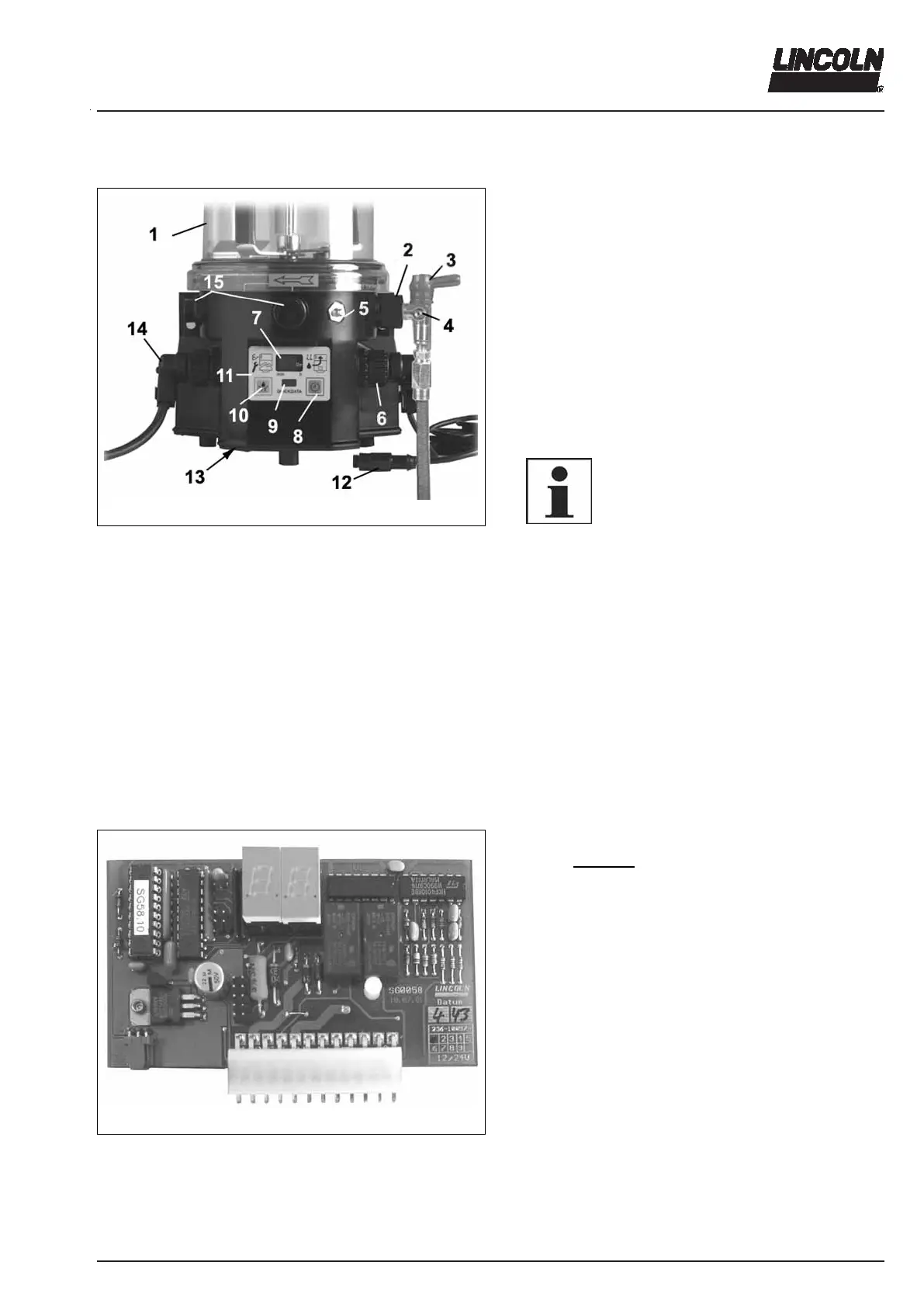

Fig. 3 Control p.c.b. MF00 (P223)

P223 without data logger

Control p.c.b. MF00

The control unit is installed in the housing of the pump

behind the membrane keypad (see pos. 11, fig. 2) as an

integrated p.c.b. MF00.

Loading...

Loading...