Page 10 of 48

User Manual

Operation Instructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Description, continuation

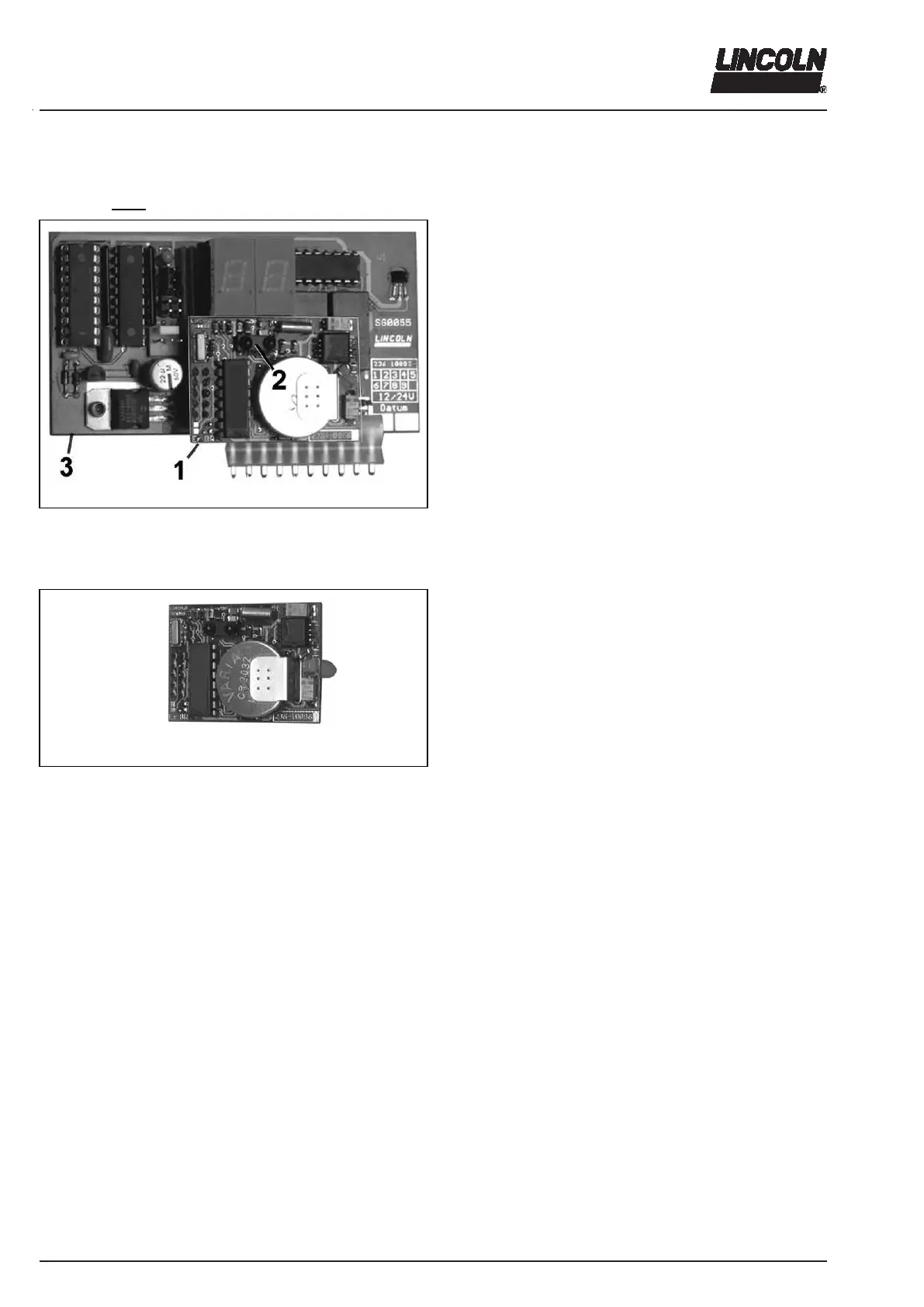

P233 with data logger

6288a01

Fig. 4 Control p.c.b. MDF00 with built-on data logger

1 - Data logger

2 - IR interface

3 - Control p.c.b.

Control p.c.b. MDF00

The control unit is installed in the housing of the pump

behind the membrane keypad (see pos. 11, fig. 2, page 9)

as an integrated p.c.b. MDF00.

The data logger (fig. 4, pos. 1) is fixed onto the p.c.b.

Control and monitoring system QuickData

®

The control and monitoring system consists of:

- control p.c.b. MDF00 (pos. 3, fig. 4)

- built-on data logger module with IR interface

(pos. 2, fig. 4)

- membrane keypad with display (pos. 3, fig. 2)

- IR interface module RS 232 (COM) for laptops, PDA

and Palm

- Lincoln diagnostic software QuickData

®

- monitored metering device model SSV with integrated

piston detector (comp. fig. 22, page 17)

4357a01

Fig. 5 Data logger module

Data logger module

Pump 233 is equipped with a readable data memory (data

logger) QuickData

®

.

The data logger renders information regarding system

settings, events such as low-level indications, malfunc-

tions, operating times and lubrication cycles.

By means of the Lincoln diagnostic software QuickData

®

the above-mentioned data can be read on a suitable lap-

top via an infrared interface (see User Manual “Diagnostic

Software QuickData

®

).

Control Unit

Control p.c.b.

The centralized lubrication system is monitored, i.e.

events such as malfunctions of the centralized lubrication

system, faults in the elapse of the operating time, low-

level indications, pause time, residual pause times of the

pump are displayed in the display window of the mem-

brane keypad.

Version P233 additionally transmits data into the data

logger.

Data memory

The following events are memorized in the EEPROM of

printed circuit boards MF00 (P223) or MDF00 (P233). How-

ever, they can be read and analyzed only out of pumps 233

via the Lincoln diagnostic software QuickData

®

:

Malfunctions (start, end and duration) in the centralized

lubrication system

faults in the elapse of the operating time

low-level indication (start, end and duration)

number of connections and disconnections of the power

supply

automatically triggered lube cycles

manually triggered lube cycles

operating data

customer related data

Loading...

Loading...