TRANSMISSION

Ch 2 page 214 Ch 2 page 215

TRANSMISSION

SHOP MANUAL MT26/31 - 08.2006 SHOP MANUAL MT26/31 - 08.2006

TRANSMISSION

Ch 2 page 214 Ch 2 page 215

TRANSMISSION

SHOP MANUAL MT26/31 - 08.2006 SHOP MANUAL MT26/31 - 08.2006

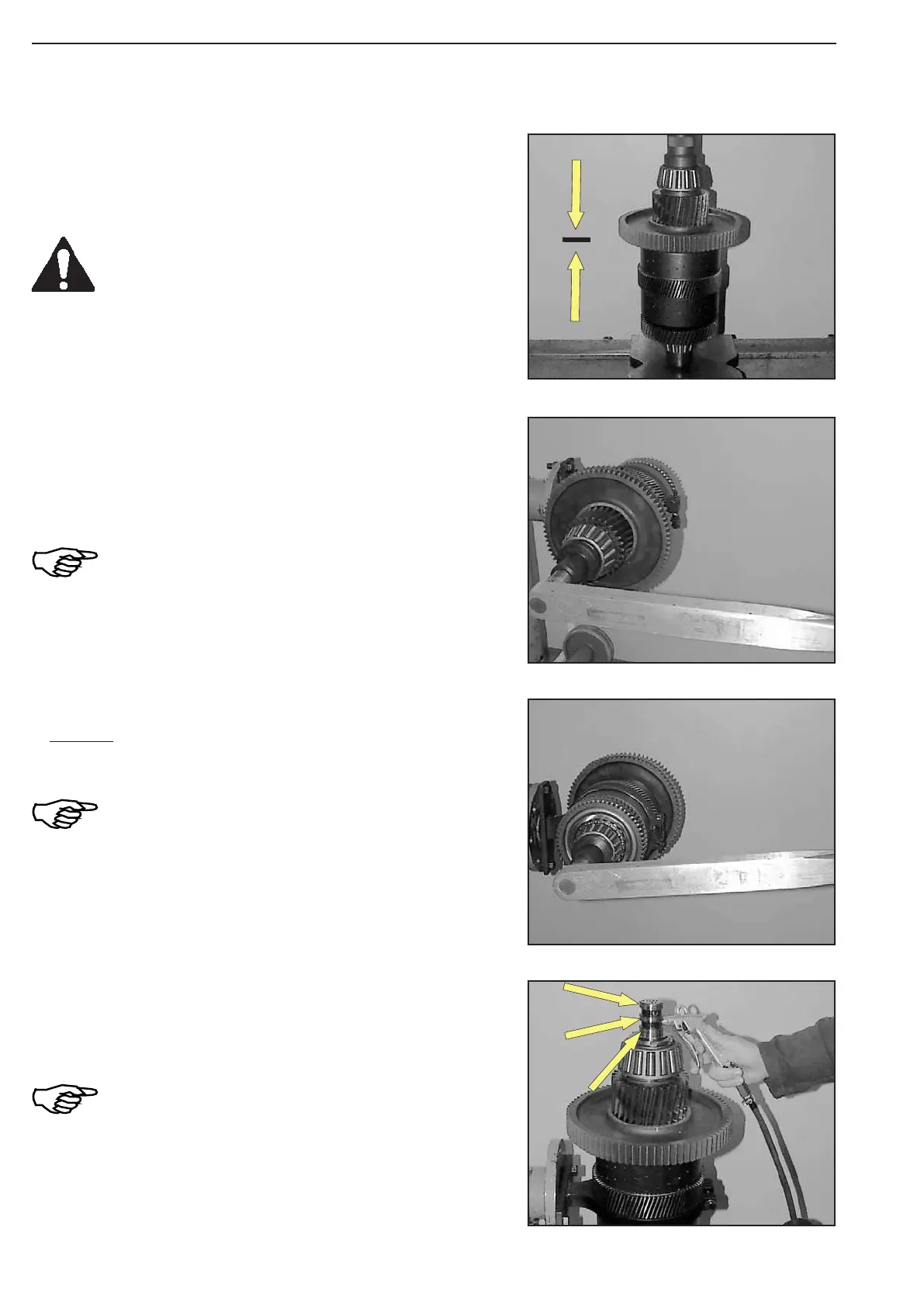

Figure 314

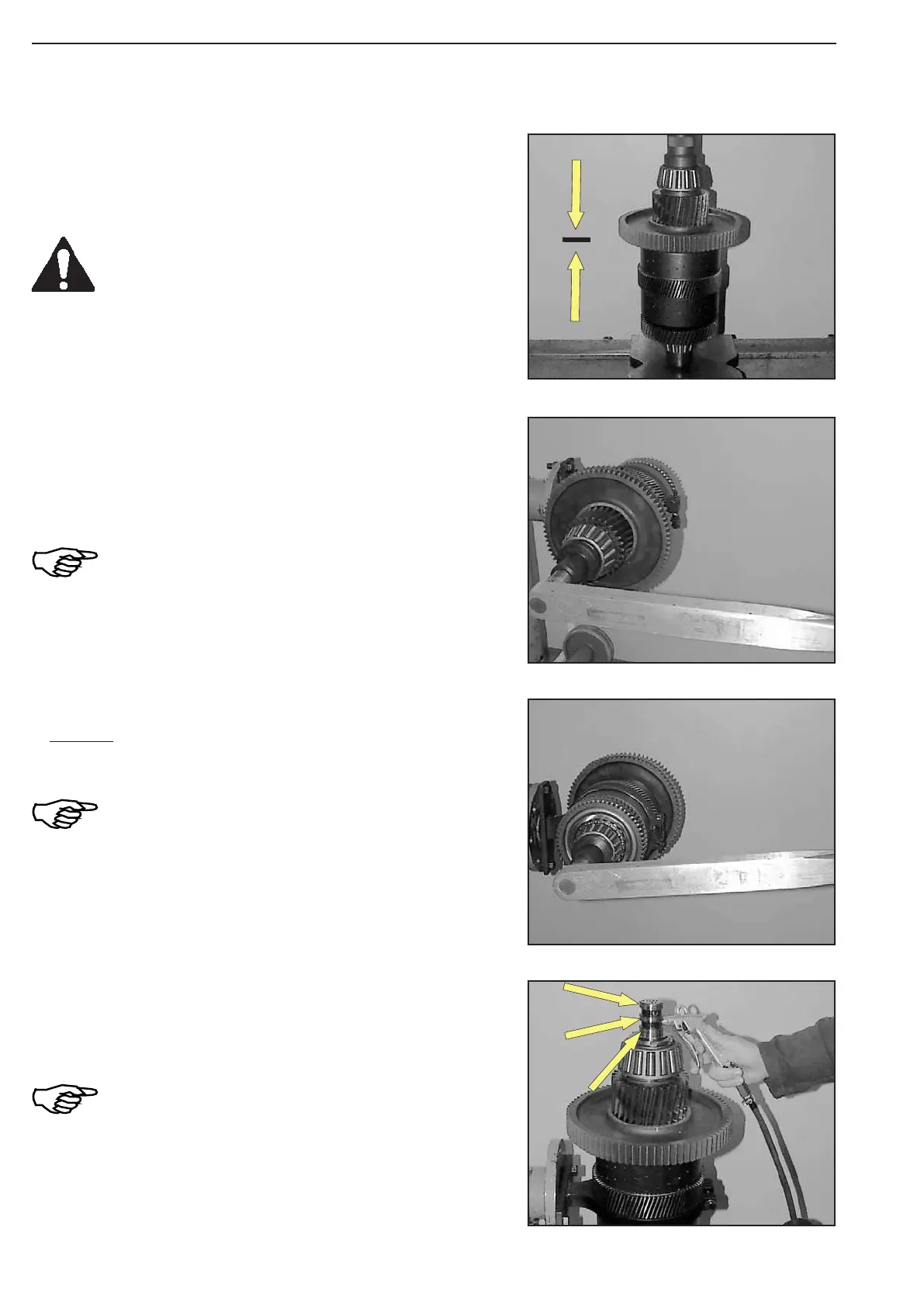

Figure 317

Figure 316

Figure 315

Lift plate carrier off the clamping ring (S).

To ensure the exact contact of the components, pre-load bearing

with 100 000 N (10 t) (Figure 314).

Support at the lower as well as the upper

bearing race!

Use pressure piece (S)!

(S) Pressure pieces 504218

Check functioning of clutches-K3 and K4 with compressed air

(Figure 317).

At correctly installed components, engaging

and disengaging of the clutch is clearly

audible!

Squeeze in and engage rectangular ring (3x, see arrow).

KR-side:

Wet thread of the slotted nut with Loctite (type-no. 262) and mount

it.

Install slotted nut with the collar (

Ø 76 mm)

facing the bearing inner race!

Torque limit ..................................... = 800 Nm

(S) Hook spanner 504215

Lift plate carrier into clamping ring (S) and fix it.

Tilt clutch 90°.

K2-side:

Wet thread of the slotted nut with Loctite (type-no. 262) and

mount it (Figure 315).

Install slotted nut with the chamfer facing the

bearing inner race!

Torque limit ..................................... = 800 Nm

(S) Clamping ring 504226

Or 504227

(S) Hook spanner 504215

Loading...

Loading...