7. TESTING ADDITIONAL FUNCTIONAL TESTING

7-9

7.3 ADDITIONAL FUNCTIONAL TESTING

7.3.1

OVERLOAD CURVE TEST

The SR469 specification for overload curve timing accuracy is ±100ms or ±2% of time to trip. Pickup accuracy is as per the current inputs

(±0.5% of 2xCT when the injected current is < 2xCT and ±1% of 20xCT when the injected current is ≥ 2xCT). Perform the steps below to

verify accuracy.

1. Alter the following setpoints:

SETPOINT S2:SYSTEM SETUP\CURRENT SENSING\PHASE CT PRIMARY: 1000

SETPOINT S2:SYSTEM SETUP\ CURRENT SENSING \MOTOR FULL LOAD AMPS FLA: 1000

SETPOINT S5 THERMAL MODEL\THERMAL MODEL\SELECT CURVE STYLE: Standard

SETPOINT S5 THERMAL MODEL\THERMAL MODEL\OVERLOAD PICKUP LEVEL: 1.10

SETPOINT S5 THERMAL MODEL\THERMAL MODEL\UNBALANCE BIAS K FACTOR: 0

SETPOINT S5 THERMAL MODEL\THERMAL MODEL\HOT/COLD SAFE STALL RATIO: 1.00

SETPOINT S5 THERMAL MODEL\THERMAL MODEL\ENABLE RTD BIASING: No

SETPOINT S5 THERMAL MODEL\O/L CURVE SETUP\STANDARD OVERLOAD CURVE NUMBER: 4

2. Any trip must be reset prior to each test. Short the emergency restart terminals momentarily immediately prior to each overload curve

test to ensure that the thermal capacity used is zero. Failure to do so will result in shorter trip times. Inject the current of the proper am-

plitude to obtain the values as shown and verify the trip times. Motor load may be viewed in:

ACTUAL VALUES A2:\METERING DATA\CURRENT METERING

Thermal capacity used and estimated time to trip may be viewed in:

ACTUAL VALUES A1:\STATUS\MOTOR STATUS

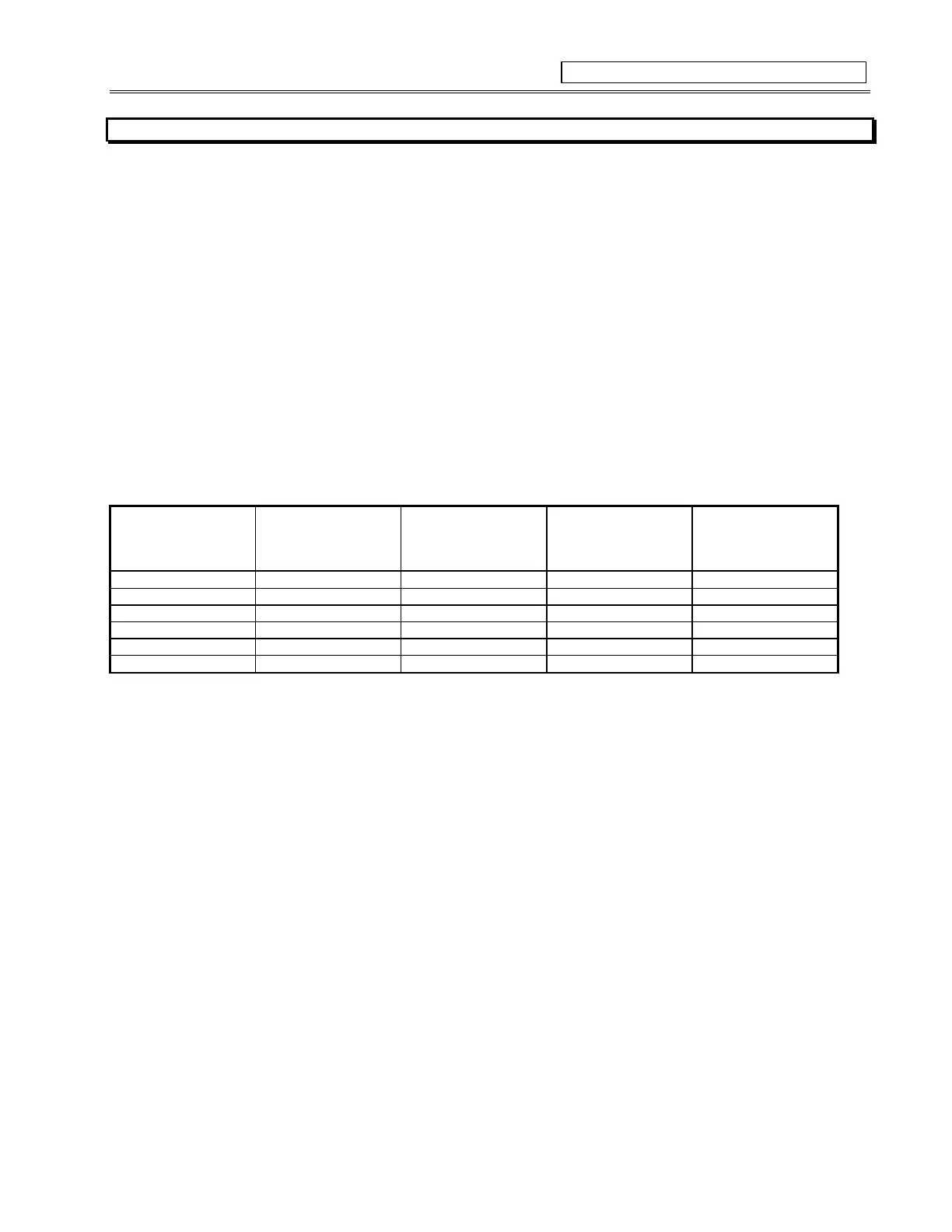

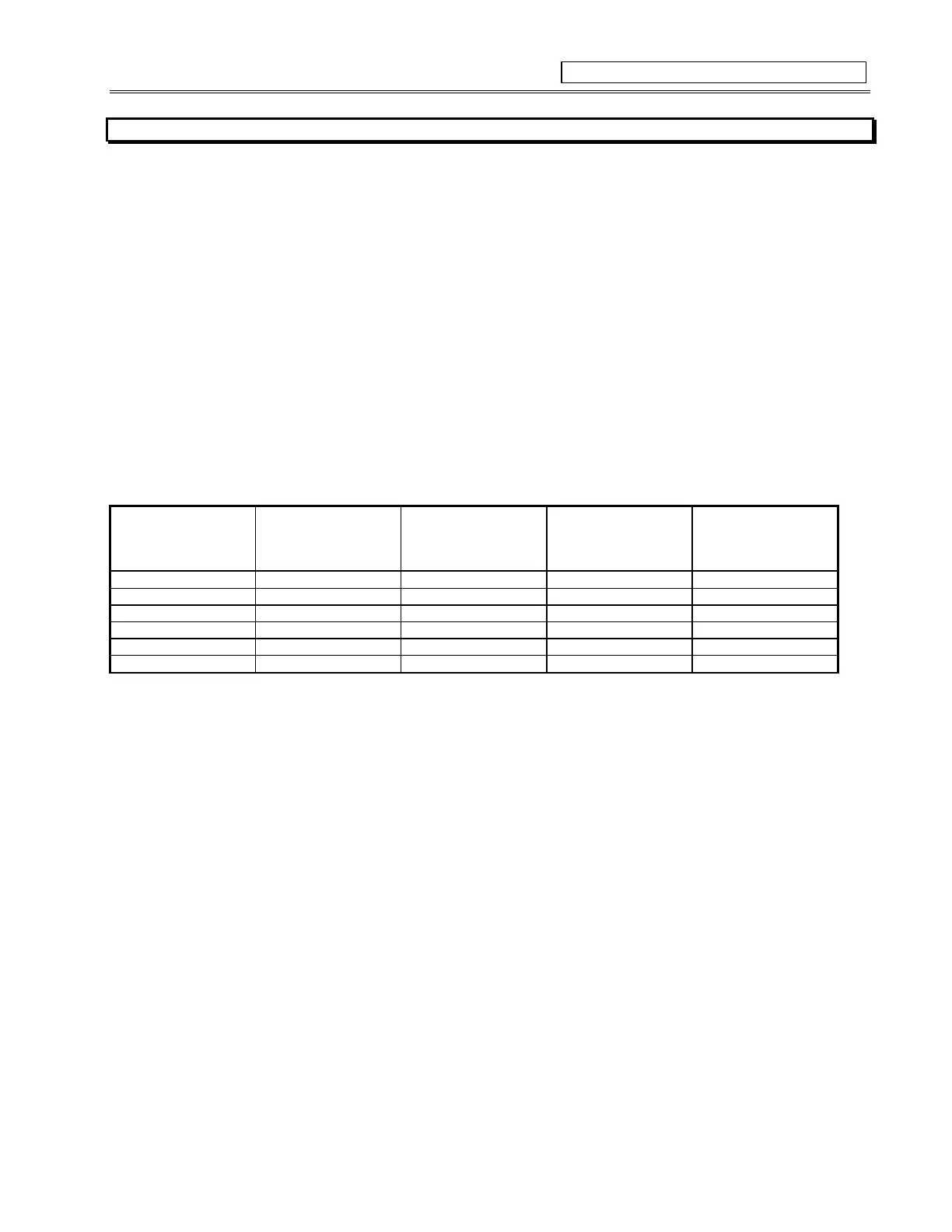

Table 7-14 OVERLOAD TEST (STANDARD CURVE #4)

AVERAGE PHASE

CURRENT

DISPLAYED

(A)

PICKUP

LEVEL

EXPECTED

TIME TO TRIP

(s)

TOLERANCE RANGE

(s)

MEASURED TIME TO

TRIP

(s)

1050 1.05 never n/a

1200 1.20 795.44 779.53-811.35

1750 1.75 169.66 166.27-173.05

3000 3.00 43.73 42.86-44.60

6000 6.00 9.99 9.79-10.19

10000 10.00 5.55 5.44-5.66

Loading...

Loading...