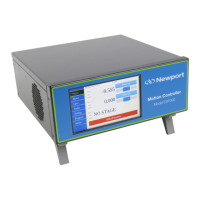

What to do if the Newport Controller axis does not move?

- CCheryl JacksonAug 3, 2025

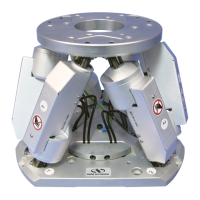

If the axis does not move, first verify that the motion device is connected to the correct driver card, as specified by the labels. Next, check that all relevant parameters (PID, velocity, etc.) are set properly.