4.21 EDH0162En1040 – 06/99

MM4005 Motion Control Tutorial

Encoders

PID closed-loop motion control requires a position sensor. The most widely

used technology by far are incremental encoders.

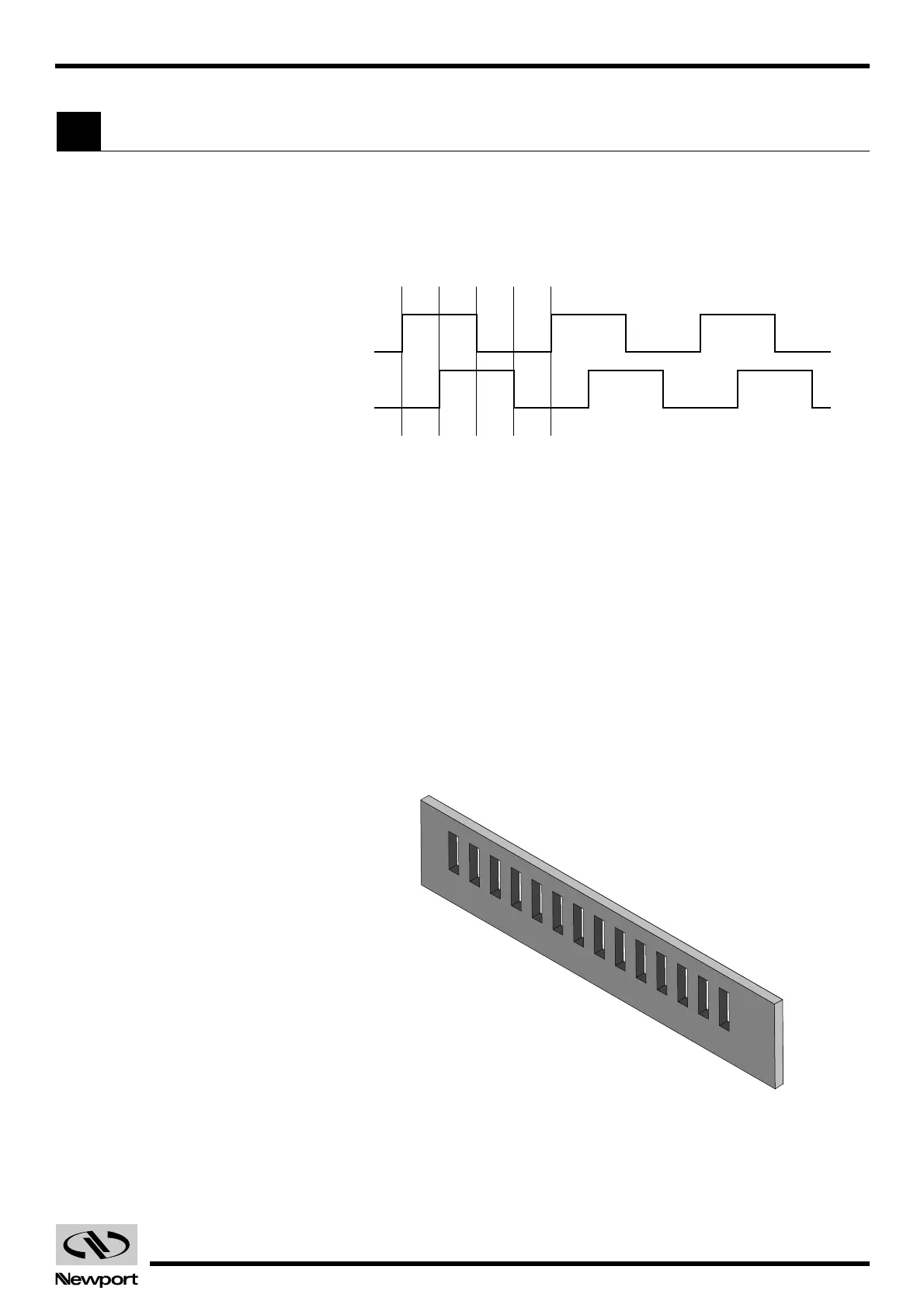

The main characteristic of an incremental encoder is that it has a 2-bit gray

code output, more commonly known as quadrature output (Fig. 4.26).

Fig. 4.26 — Encoder Quadrature Output.

The output has two signals, commonly known as channel A and channel B.

Some encoders have analog outputs (sine - cosine signals) but the digital

type are more widely used. Both channels have a 50% duty cycle and are

out of phase by 90°. Using both phases and an appropriate decoder, a

motion controller can identify four different areas within one encoder

cycle. This type of decoding is called X4 (or quadrature decoding), mean-

ing that the encoder resolution is multiplied by 4. For example, an encoder

with 10 µm phase period can offer a 2.5 µm resolution when used with a X4

type decoder.

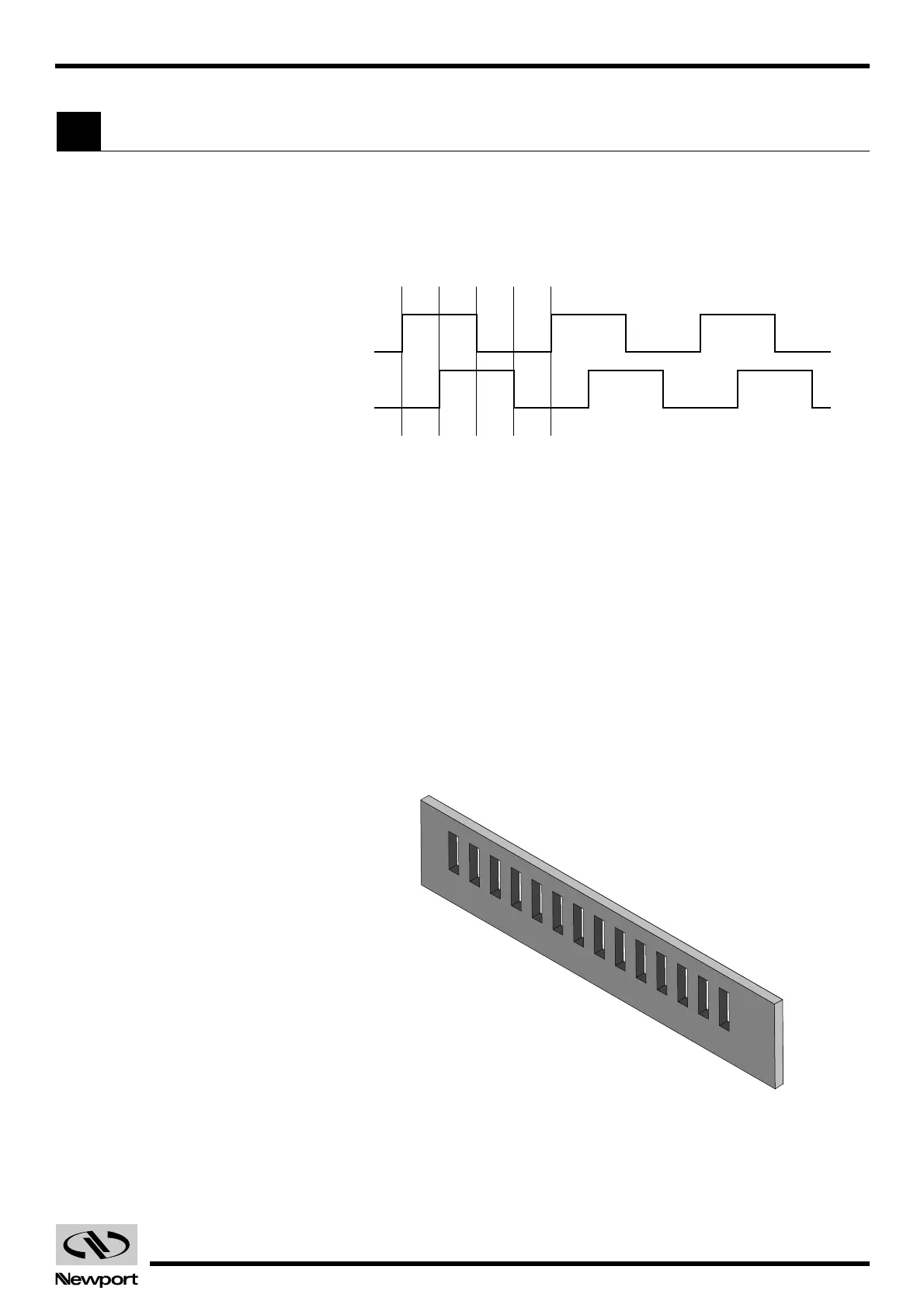

Physically, an encoder has two parts: a scale and an read head. The scale is

an array of precision placed marks that are read by the head. The most

commonly used encoders, optical encoders, have a scale made out of a

series of transparent and opaque lines placed on a glass substrate or

etched in a thin metal sheet (Fig. 4.27).

Fig. 4.27 — Optical Encoder Scale.

The encoder read head has three major components: a light source, a mask

and a detector (Fig. 4.28). The mask is a small scale-like piece, having iden-

tically spaced transparent and opaque lines.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...