NewSonic SonoDur2 Issue 04 09/2016 Page 65

11.2 Technical Data – SonoDur2

UCI Method, corresponds to DIN 50159, ASTM A1038

Test loads

Newton scale (1kgf = 9.81 N)

Motor probes: 1N (0.1 kgf), 3N (0.3kgf) and 8.6 N (0.8 kgf)

Handheld Probes: 10N (1 kgf), 49N (5kgf), 98N (10kgf)

(Other test loads on request)

Hardness scales and range

(according to relevant standards), in this

case table A1 respectively T1, T2 (low

alloy steel). Different measuring ranges

are valid for other materials. When

exceeding the limits the conversion range

will be extended. The calculated values

are highlighted in red besides the original

data in HV.

Note:

Conversions are acc. to latest ASTM E140-

12b

Ԑ1

(2013) und EN ISO 18265:2014.

Conversions into tensile strength: 98N

(10kgf) test load only.

Rockwell (EN ISO 18265 only)

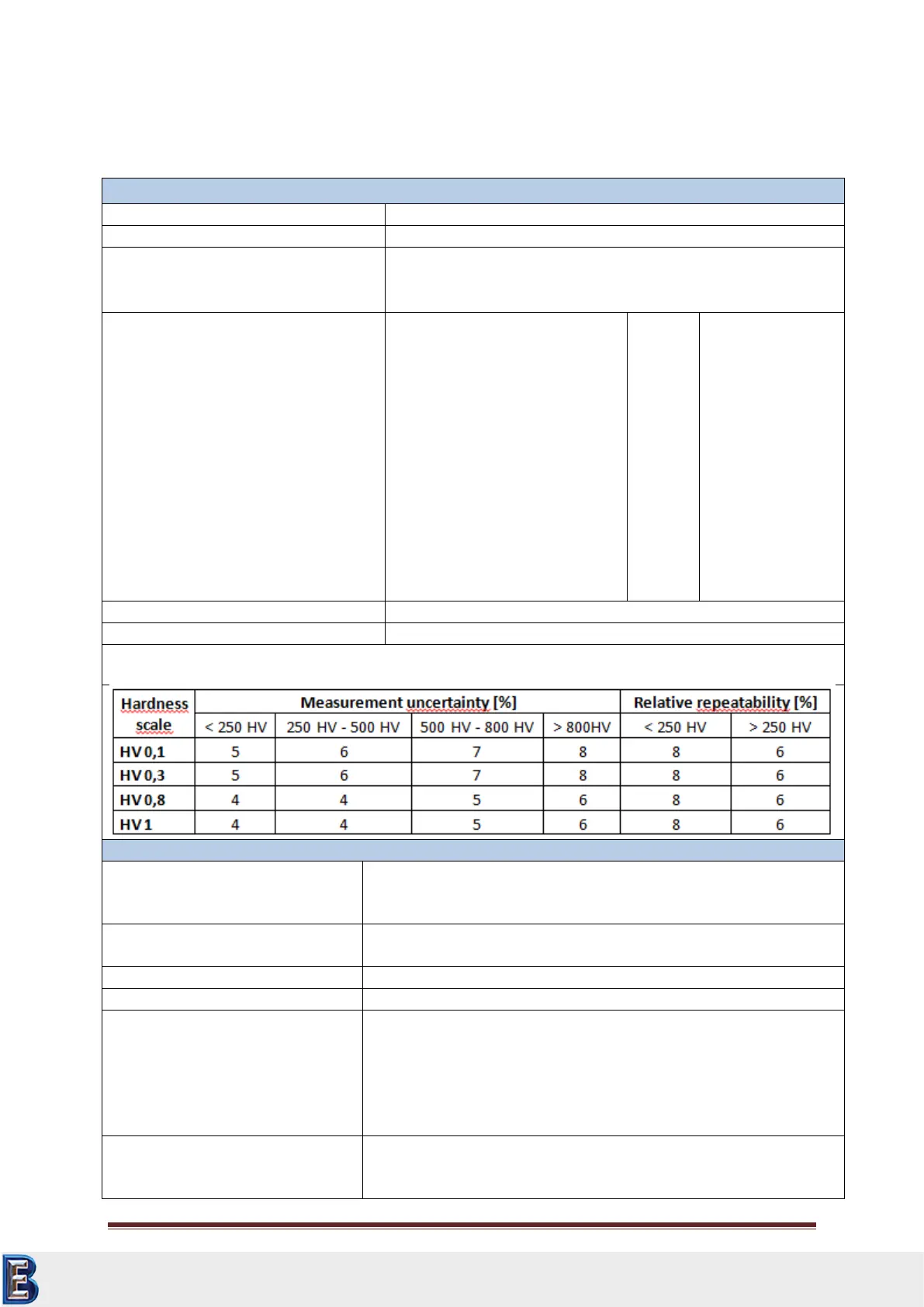

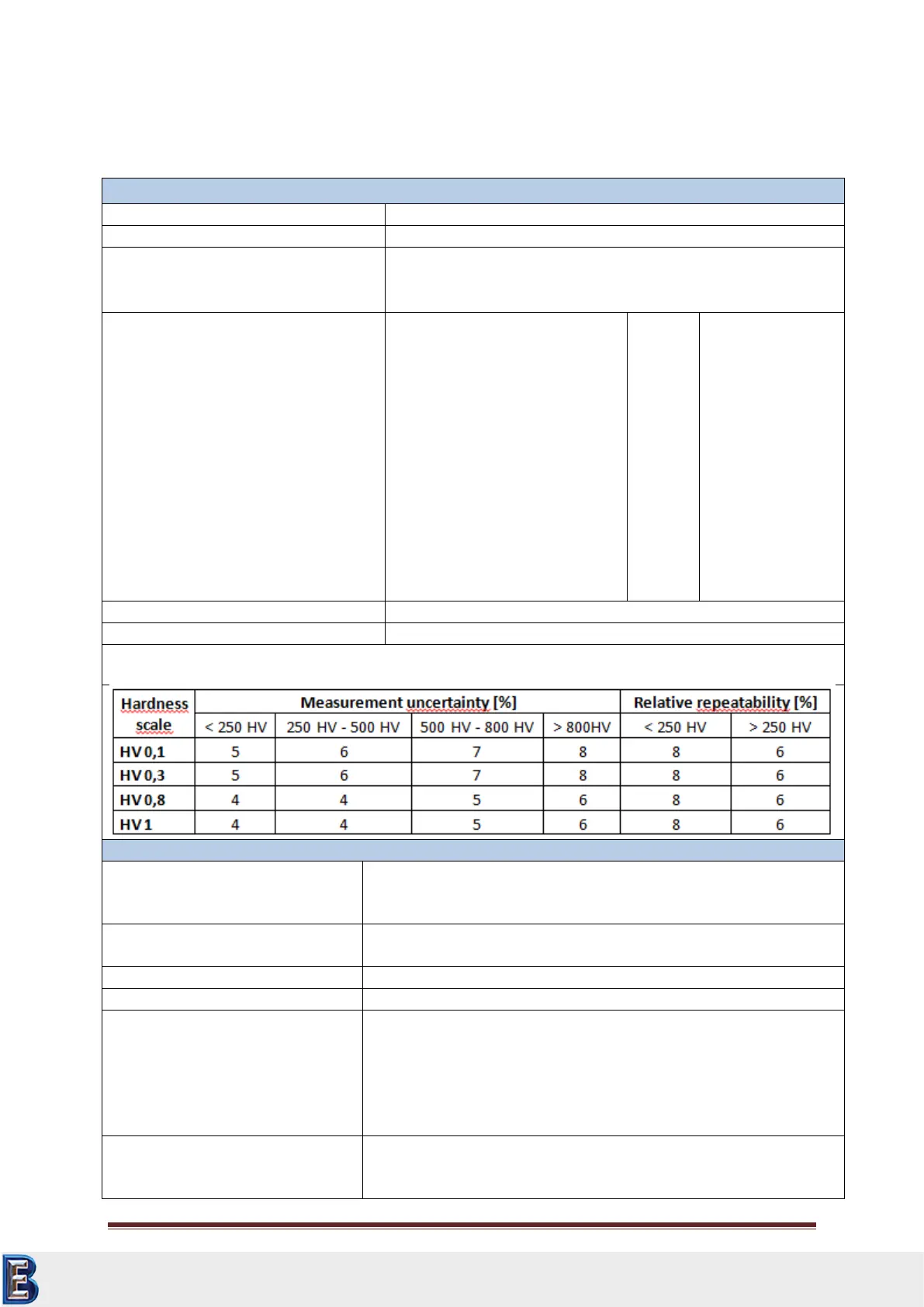

< 4 % (HV5, HV 10). For other test loads and ranges see table below.

< 5 % (HV5, HV 10). For other test loads and ranges see table below.

*exceeds DIN 50159, dependent on test load and range (see table below). Specifications are valid for 5

measurements using Vickers reference blocks and according to test conditions given in standard DIN 50159.

Mechanical and Environmental (Instrument and probe)

>8 hours in measurement operation (depending on system

performance, temperature and instrument settings), up to 6 hours

continuous operation, quick exchangeable battery pack

Probe: 0°C to ~ +50°C

Instrument: -10° ~ +50°C // Charging +10°C ~ +45°C

Instrument ca. 153x78x29 (26) mm

Motor probe Ø38mm, L=190 mm

Handheld probe Ø25 mm, L=176 mm

(free length oscillation rod ca. 12,5 mm)

Handheld probe Ø25 mm, L=207 mm

(free length oscillation rod ca. 43 mm)

Instrument ca. 280 gr

Handheld probe ca. 280 gr

Motor probe ca. 370 gr

Your Complete Source for

Testing Equipment. Since 1969!

www.BergEng.com

Berg Engineering & Sales Company, Inc.

Tel 847-577-3980

info@bergeng.com

Loading...

Loading...