NewSonic SonoDur2 Issue 04 09/2016 Page 68

11.4 Formulas and Terms

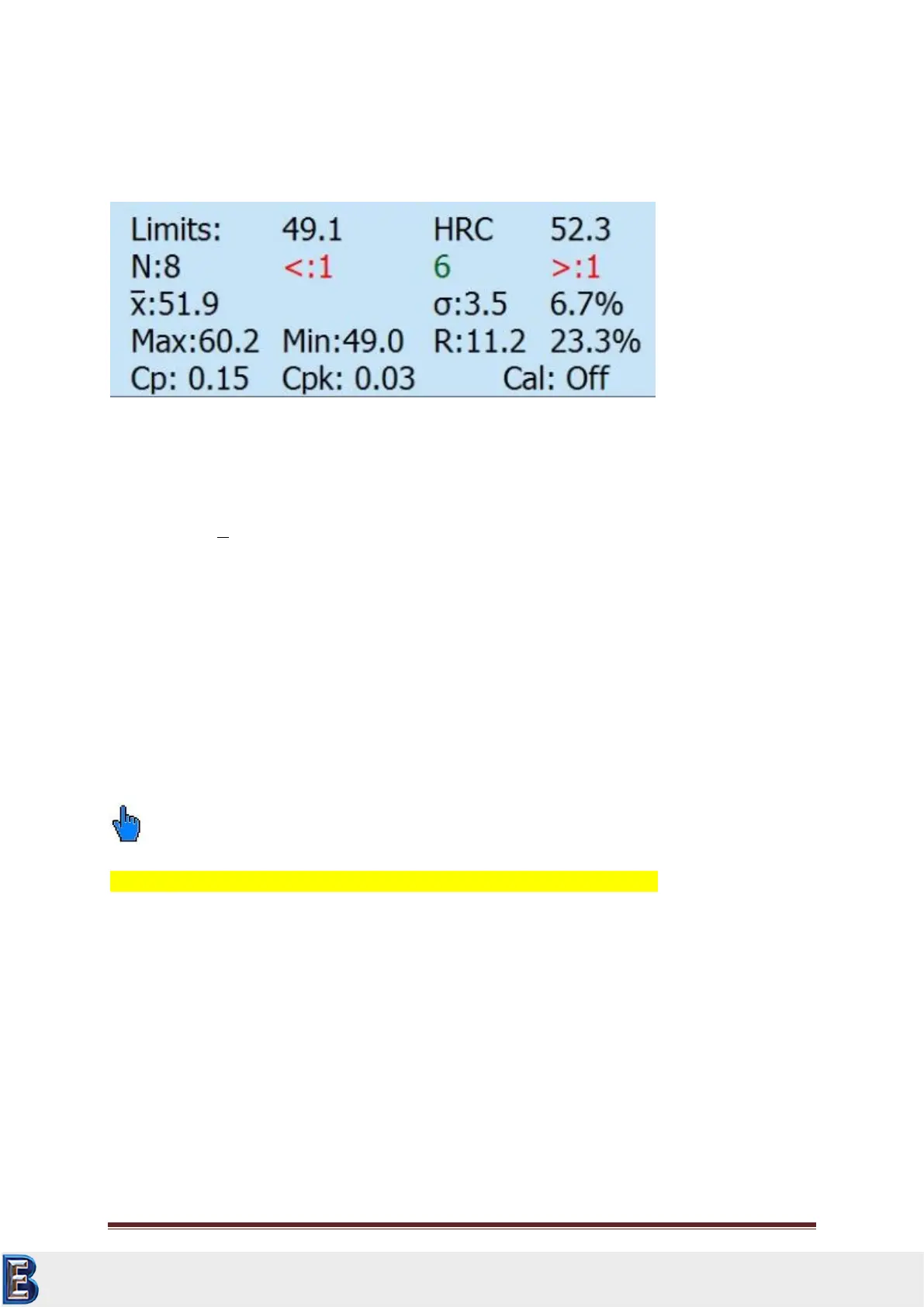

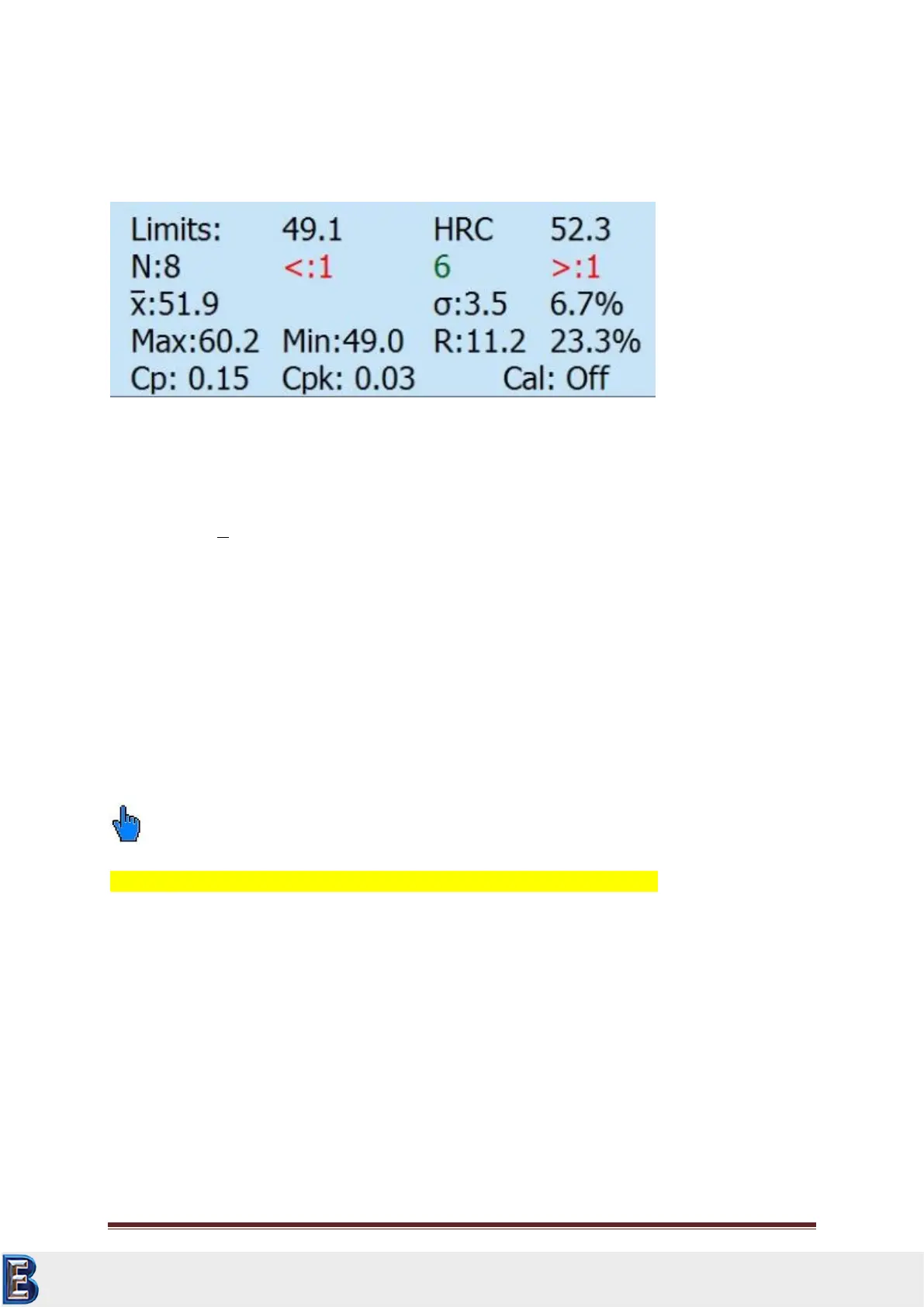

Section 7.5 “Information Menu“, contains calculation results that are described in detail below (see

also EN ISO 18265).

Average value in Figure 11.1 is represented by the letter X with a bar over it, here referred to as

“Overline X”.

With X(i) = Individual Hardness Measurement Value, N = Total Quantity of Measurements

If hardness gradient measurements are not performed, the average value is usually the characteristic

degree of hardness for a material or for a particular test position on the test object. Impacts caused

by the operator and/or material inhomogeneity effects can be reduced by averaging. (Highly

heterogeneous materials such as GG or GGG-cast iron are an exception).

R = Range/spread or maximum error in a series of measurements (absolute value):

R = X(Max) – X(Min) (2)

Please note:

Relative range is defined dependent on the used scale according EN ISO 18265:

______ R ____

100 - Overline X

______ R_____

130 - Overline X

Your Complete Source for

Testing Equipment. Since 1969!

www.BergEng.com

Berg Engineering & Sales Company, Inc.

Tel 847-577-3980

info@bergeng.com

Loading...

Loading...