EN

English – 5

3.4 - Barrier lift fixture

3.4.1 - If the support surface already exists

01. Open the cabinet of the barrier (fig. 13);

02. Place the barrier on the fixing surface and trace the points where the slots

are to be fixed (fig. 14);

03. Move the barrier and drill the traced surface points; then insert 4 expansion

bolts, not supplied (fig. 15);

04. Position the barrier correctly and secure by means of the relative nuts and

washers not supplied (fig. 16).

3.4.2 - If the support surface does not exist

01. Dig the foundation pit (*) to house the foundation plate;

02. Prepare ducting for connection cables (fig. 17);

03. On the foundation plate, fix the 4 bolts, placing a nut on the upper side of

each and one on the lower side of the plate (fig. 17). Caution – The lower

nut must be tightened down to the threaded section;

04. Now cast the concrete, and before it sets, embed the foundation plate,

which must be positioned flush with the surface, parallel to the pole and

perfectly level (fig. 17). Wait for the concrete to set completely; in general,

at least 2 weeks;

05. Remove the 4 upper nuts of the bolts;

06. Open the cabinet of the barrier (fig. 18);

07. Position the barrier correctly and secure it by means of the relative nuts

and washers supplied with the foundation plate and removed in point 04

(fig. 19).

(*) Note - The fixing surface must be perfectly smooth and flat. If the surface is

in concrete, it must be at least 0.15 m thick, and must be adequately reinforced

with steel cages. The concrete volume must be greater than 0.2 m

3

(a thick-

ness of 0.25 m corresponds to 0.8 m

2

; in other words equal to a square base

of approx. 0.9 m per side). Anchoring to the concrete can be by means of 4

expansion bolts, fitted with 12 MA screws, which resist to a traction load of at

least 400 kg. If the fixing surface is in another material, the consistency must

be checked and ensure that the 4 anchoring points can resist a load of at least

1000 kg. For fixture, use 12 MA screws.

3.5 - Installing the rod and the accessories provided

3.5.1 - Pole support assembly

01. Insert the two plugs in the relative seats on the output motor shaft (fig. 20);

02. Position the support on the output motor shaft, placing it in the “vertical

pole” position and tighten the relative screws and washers fully down to

secure (fig. 21);

03. Position the pole cover and partially secure by means of the 6 screws sup-

plied (fig. 22).

3.5.2 - Assembling a pole formed of a single piece, whole or cut.

Possible lengths:

M3BAR: 2,65 m = XBA15 (3,15 m -0,50 m = 2,65 m)

3,15 m = XBA15 (3,15 m)

M5BAR: 3,50 m = XBA14 (4,15 m -0,65 m = 3,50 m)

4,15 m = XBA14 (4,15 m)

5,15 m = XBA5 (5,15 m)

M7BAR: 5,15 m = XBA5 (5,15 m)

01. Assemble the two pole insertions (fig. 23);

02. Insert, from the same end of the pole, the insertions just assembled. Use a

rubber mallet (fig. 24);

03. Lightly grease the aluminium guide on both sides (fig. 25);

04. Perform this operation on both ends of the pole: insert the first part of im-

pact protection rubber in the slot, through to the end of the pole; then in-

sert the joint for the impact protection rubber (fig. 26) and repeat with all

parts;

XBA13

M3BAR

L9BAR

M7BAR

M5BAR

M3BAR

2,65 m 3,15 m 3,50 m 4,15 m 5,15 m 7,33 m 9,33 m

L9BAR

M7BAR

M5BAR

XBA15

+ XBA14

XBA5

(5,15 m)

XBA14

(4,15m)

XBA14

(4,15m) –0,65m

XBA15

(3,15m)

XBA15

(3,15 m) –0,50m

XBA14

+ XBA5

A

WA13

WA12

XBA4 /

XBA6 / XBA18

XBA11

(0)

(1)

(1)

(5)

(0)

(1)

(1)

(4)

(0)

(1)

(2)

(4)

(0)

(1)

(1)

(3)

(0)

(1)

(1)

(3)

(0)

(1)

(2)

(3)

(0)

(1)

(2)

(3)

0÷1=

A

1

A

3

C

2

B

2

A

1

A

3

B

2

B

2

B

3

B

3

C

2

B

2

B

3

B

3

C

1

C

3

B

1

B

1

XBA13

?

M5BAR

L9BAR

M7BAR

M5BAR

3,50 m 4,15 m 5,15 m 5,00 m 6,33 m 7,33 m 8,33 m

L9BAR

M7BAR

XBA15

+ XBA14

XBA15

+ XBA15

XBA15+XBA15

(6,30m) –1,30m

XBA5

(5,15m)

XBA14

(4,15m)

XBA14

(4,15m) – 0,65m

XBA14

+ XBA14

B

?

2÷7=

0÷1=

2÷4=

5÷6=

0÷2=

3÷5=

6÷7=

0÷2=

3÷5=

0÷2=

3÷5=

0÷2=

3÷4=

5÷6=

0÷2=

3÷6=

B

2

B

3

B

3

C

1

C

2

A

2

A

2

A

3

B

1

B

2

B

1

B

2

A

1

A

2

A

3

A

3

B

1

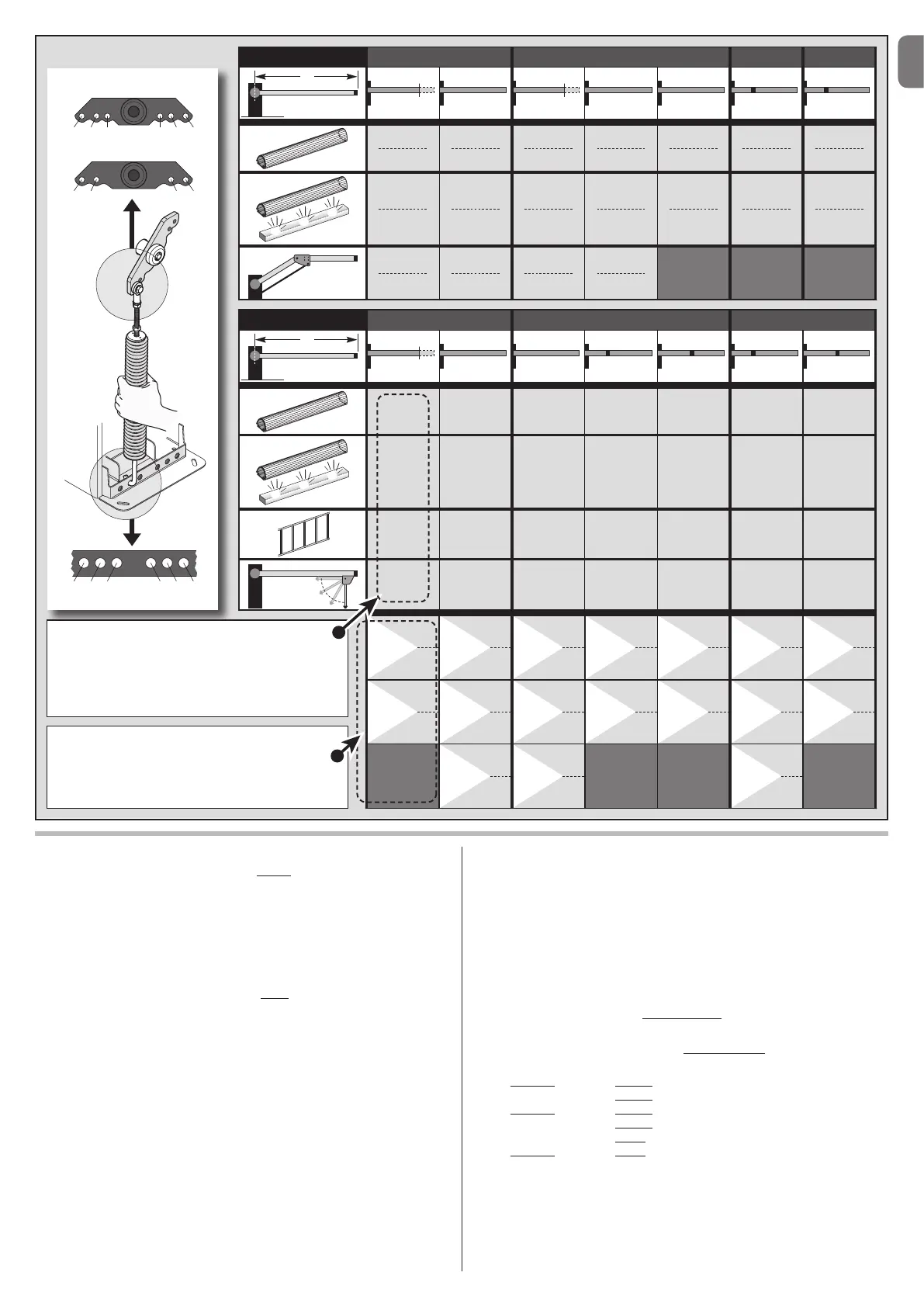

M3BAR / M5BAR

M7BAR / L9BAR

3 2 1 321

B A BA

C B A CBA

XBA13

XBA4 /

XBA6 / XBA18

XBA13

TABLE 4

1) - Add up the numbers in brackets in

the column, choosing only those corre-

sponding to the accessories installed.

2) - Use the sum of these numbers to

identify the holes to which to anchor the

spring.

Loading...

Loading...