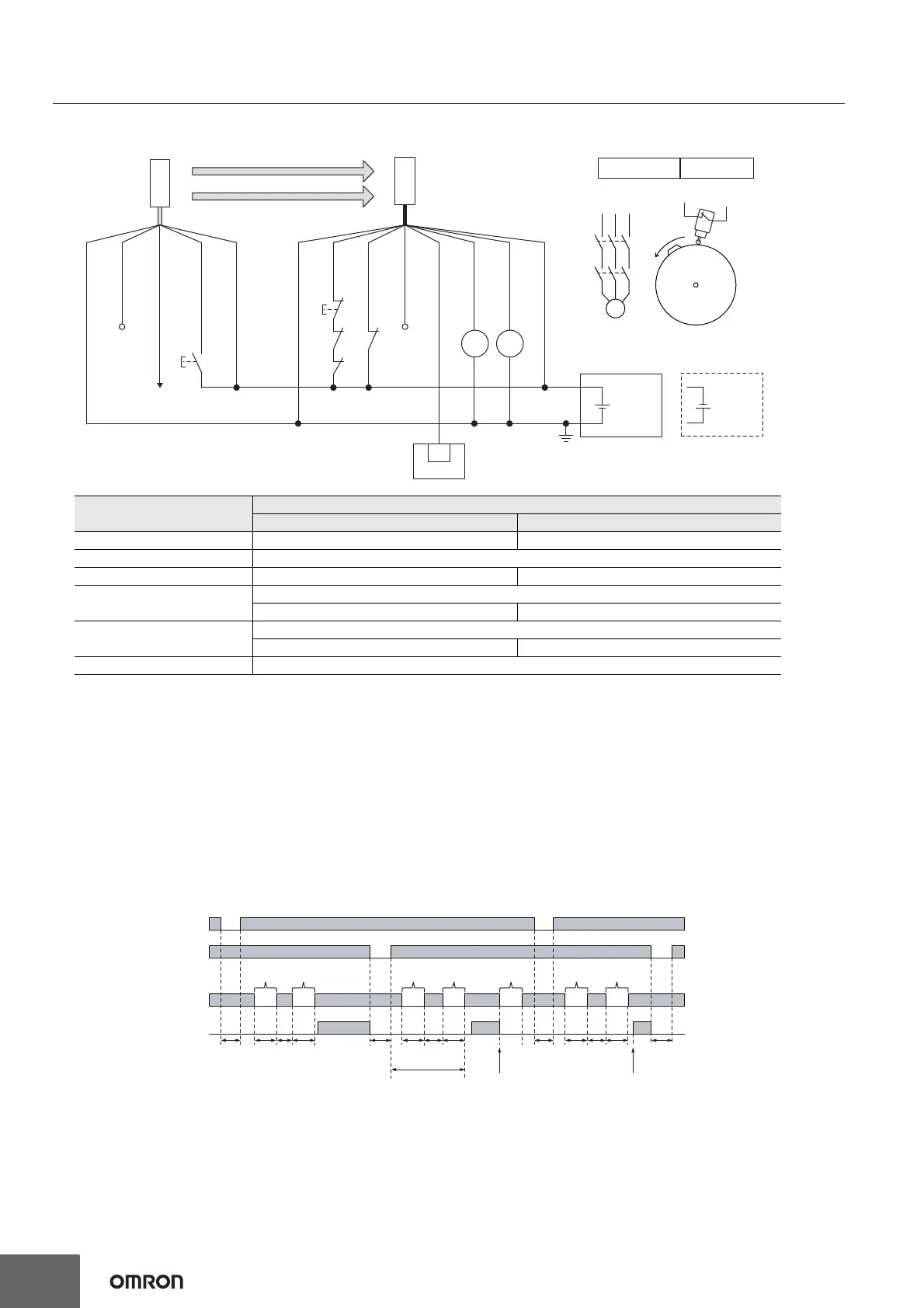

24V/0V (Brown)

0V/24V (Blue)

Not used (Pink)

PSDI (Gray)

0V/24V (Blue)

Not used (White)

OPERATING RANGE

SELECT INPUT (Yellow)

*

2

TEST (Black)

24V/0V (Brown)

RESET/EDM

(Yellow)

AUX (Red)

OSSD 1 (Black)

OSSD 2 (White)

F39-JGC-L

F39-JG

C-D

24 VDC

Wiring for NPN

*

1

24 VDC

KM1

KM2

S2

S3

S1

0VDC

KM1 KM2

*

4

IN

PLC

*

3

KM1

KM2

M

Cam

S3

Receiver

Emitter

S1: Test switch

S2: Reset switch

S3: Press position switch

KM1, KM2: Safety relay with forcibly guided contacts (G7SA)

or magnetic contactor

PLC: Programmable logic controller (Used for monitoring only.

NOT related to safety system.)

M: Motor

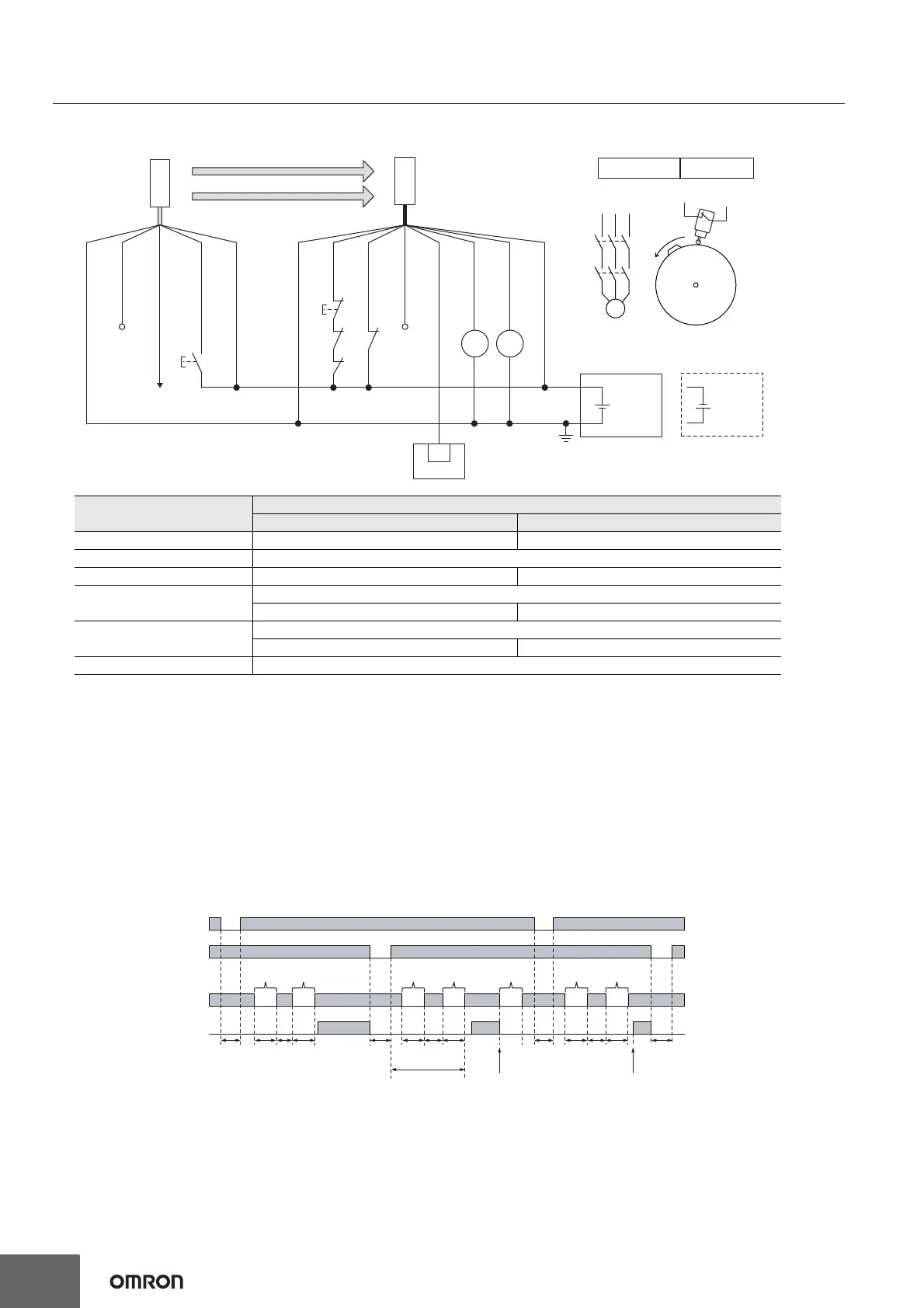

Timing chart

Reset switch (S2)

Press position switch (S3)

OSSD

T1

min.

T2

min.

T4

min.

T5

min.

T5

min.

T2

min.

T3

min.

T4

min.

T3

min.

Dummy

break

T1

min.

T2

min.

T3

min.

T4

min.

T6

Machine stops Machine restarts

Feeding

parts

Feeding

parts

Removing

parts

Unintended

block

Dummy

break *

Dummy

break *

Unblocked

Blocked

T1: Minimum pressing time of reset switch. Configurable from 100 to 500 ms in 100-ms increments by SD Manager 3.

T2: Minimum break time (300 ms)

T3: Minimum unblocked time during the time from removing to feeding parts. T3 = T1

T4: Minimum break time (300 ms)

T5: Minimum pressing time of press position switch. T5 = T1

T6: Wait time until double break is complete (30 s or less)

* When the machine is stopped by unintended block in the middle of pressing of parts, operation of the reset switch (S1) and then double dummy

break are needed for reinitiation of the machine cycle.

Intelligent Tap

Needed

*

5

: Indicates a switch position.

Function

Setting

DIP switch SD Manager 3

EDM - [External device monitoring] : Enable *5

Operating Range Selection Short : Connect the OPERATING RANGE SELECT INPUT line of the emitter to 0 VDC.

PSDI N/A [PSDI] : Double break *5

Non-Muting system

Perform wiring according to the wiring diagram.

N/A [Muting] : Disable *5

External Test used

Connect the TEST line of the emitter to 24V/0V of the emitter via a test switch (NO contact). *6

N/A [External test signal inversion] : Disable

Optical Synchronization Do not connect the COM(+) and COM(-) lines of the of emitter and receiver with each other.

*1. Reverse the polarity of the power supply when using in the NPN

system. Select a PLC of PNP or NPN type according to the system

of your application.

*2. Open or connect the line to 24 VDC if Operating Range Selection is

used in Long Mode.

*3. When connecting to the PLC, the output mode must be changed with

the SD Manager 3 according to your application. For the setting this

function, refer to the User's Manual (Man.No.Z405).

*4. This is the case for a PELV circuit.

*5. Set the function with the SD Manager 3, restore the settings to the

F3SG-SR, and perform wiring according to the wiring diagram.

*6. This wiring example shows light emission stop when connected to

24 VDC with PNP setting, and light emission stop when connected to

0 VDC with NPN setting. If TEST switch is not needed, refer to the

User's Manual (Man. No. Z405).

Loading...

Loading...