126

Chapter7

OS32C

User’s Manual

Appendix

Troubleshooting

Troubleshooting

Safety output OFF state while there is no intrusion by an object

This may happen due to:

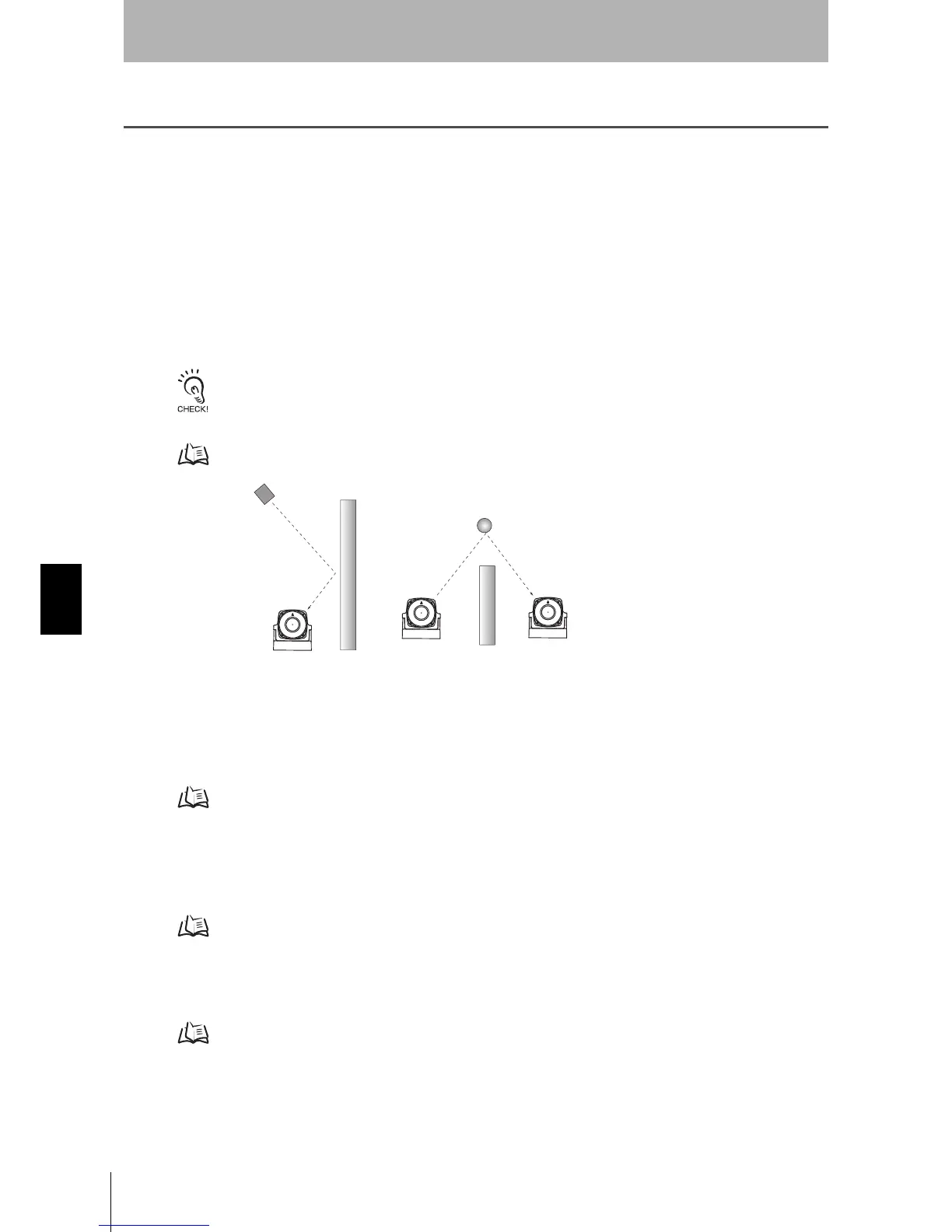

1. Mutual interference

This may happen if light from another scanner (OS32C) or other type of photoelectric sensor such as a

safety light curtain, is transmitted into the OS32C. In such a case, install the sensor so that its scanning

plane does not receive light from the other sensor.

When positioning the OS32C downward, the OS32C may be affected by reflection from the floor surface. Effect of

reflection may increase depending on the material of the screen. Be sure to check surrounding environment before

installing the OS32C.

For mounting, see Chapter 4 Installation.

Fig. 7-1

2. Incorrect monitoring zone configuration

A safety zone may have been configured too close to any objects. Since the maximum measurement

error of the OS32C is 100mm, the safety zone must be configured at least 100mm away from any

objects. An additional measurement error may need to be added due to reflective backgrounds.

Additional Error due to Reflective Background p.131

3. Incorrect zone delay setting

The OS32C will turn OFF if the zone set select input pattern does not fit to any of the patterns

configured with the configuration tool within the configured zone delay time. Set the zone delay time to

adjust to the specified zone set select input pattern within the given zone delay time.

Zone Set Switching p.25

4. Bright light/Stroboscopic light

Ambient light including high density factory lighting and strobe flash may directly affect the OS32C. An

angle of +/-5 degrees must be maintained from the laser scanning plane.

Mounting Considerations p.84

Loading...

Loading...