No. P10355

|17|

8.

CONNECTION PROCEDURE AND GROUND FOR SAFETY USE (continued)

WARNING

Follow the instructions below to avoid electric shock.

Touching the charging parts may result in fatal electric shock and severe burn.

Do not touch the charging parts of the welding machine.

Have a qualified electric engineer ground the case of the welding power source and the base

metal or jig electrically connected in accordance with a local low.

With the line disconnect switch in the switch box all touched off, ground and connect the

welding machine.

CAUTION

Be sure to install a switch with fuse or a circuit breaker (for motor) to the input sides of each

welding machine.

CAUTION

Be sure to ground the case of the welding power source.

Use a grounding cable of which thickness is more than AWG9 (10mm

2

).

If the welding power source which is not grounded is used, voltage will be generated in the

case through the capacitor between the welding power source input circuit and the case or

floating capacity (electrostatic capacity naturally generated between the input conductor and

the case metal). If you touch the case or the base metal, you may suffer from electric shock.

Be sure to ground the case of the welding power source.

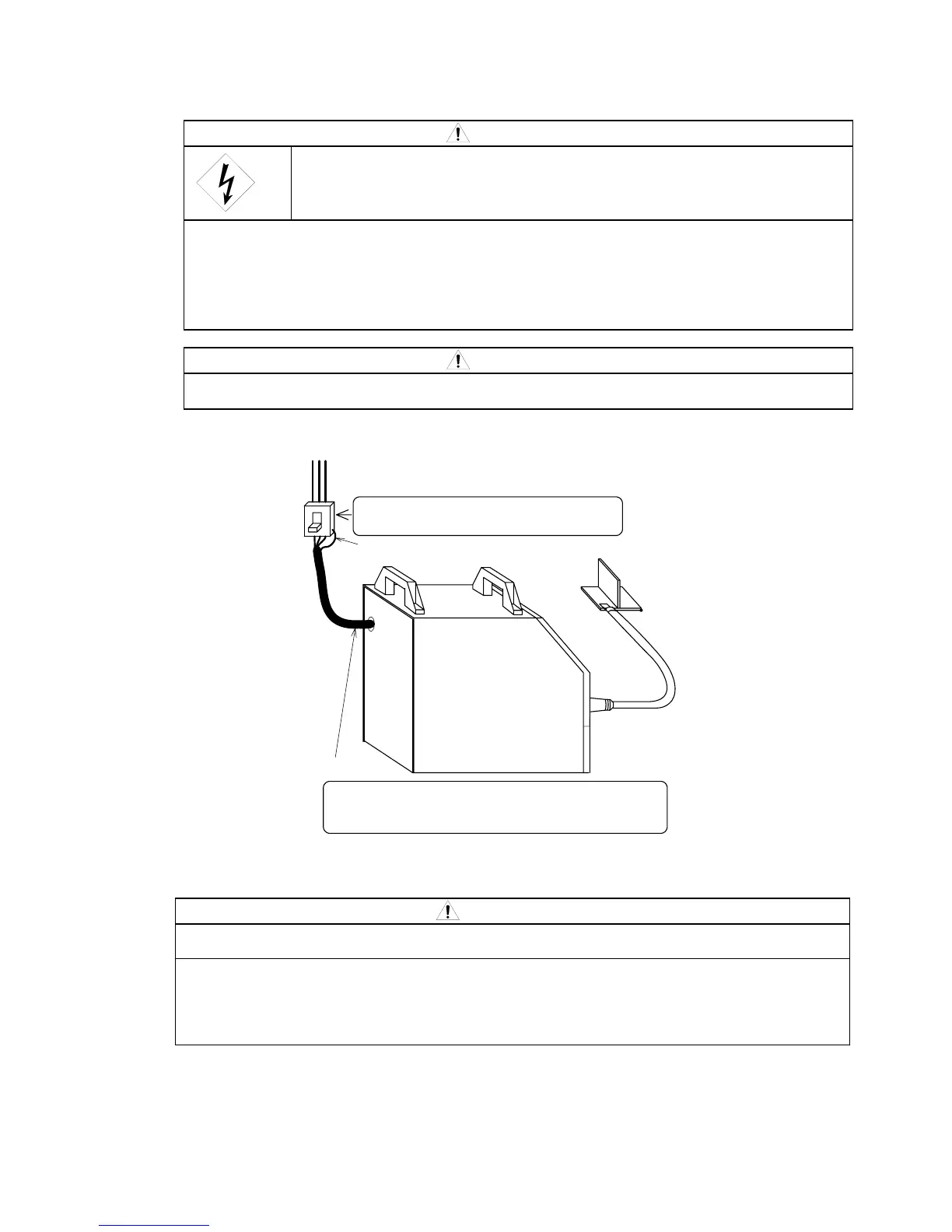

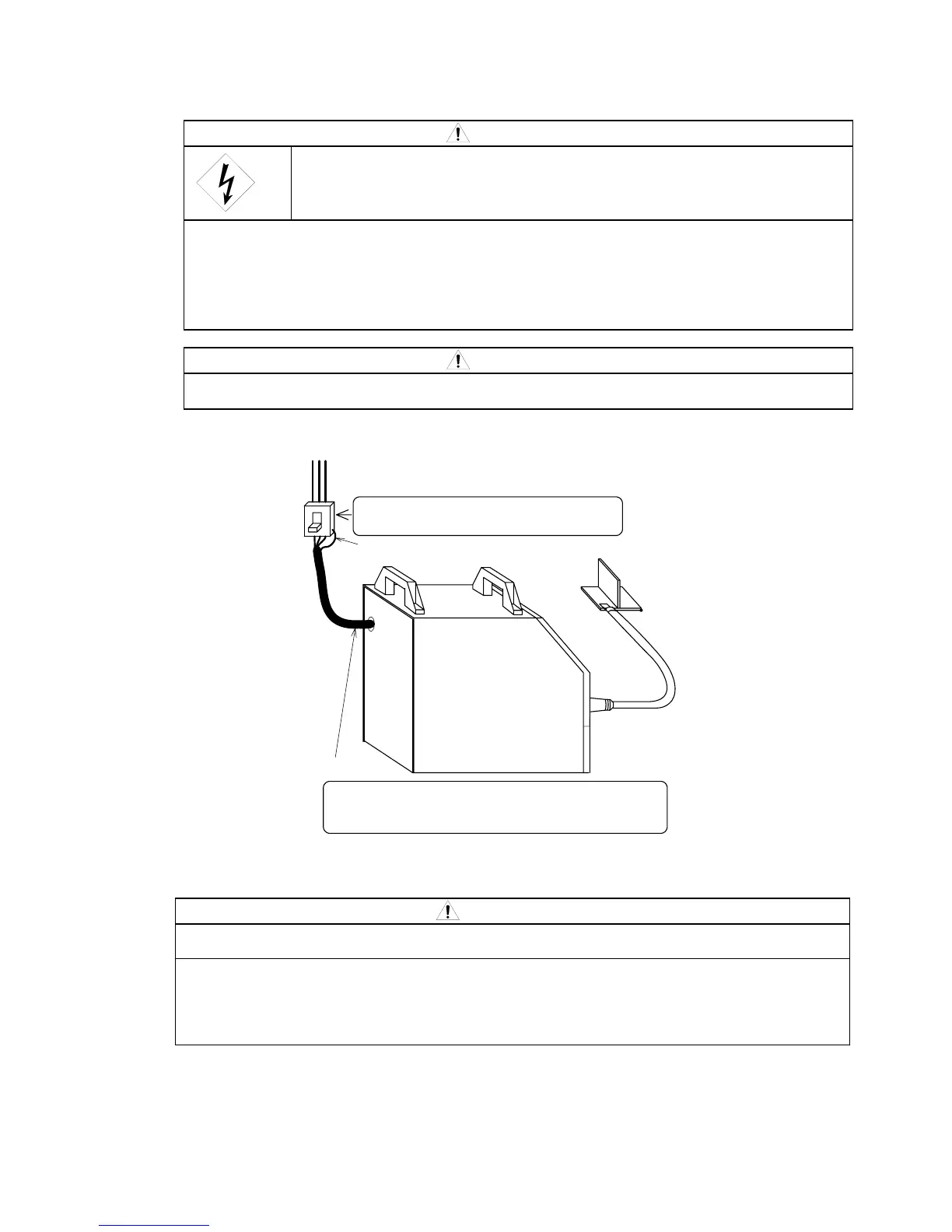

Mount a switch with fuse or a circuit breaker

on each welding machine.

GREEN cable

for

Grouding cable

Base metal/JIG

Input cable

Surely connect the input and grounding cables

AWG9 (10mm

2

) to the circuit breaker .

Loading...

Loading...