No. P 10355

• | 61• |

11. AP P LIE D FUNC TION (continued)

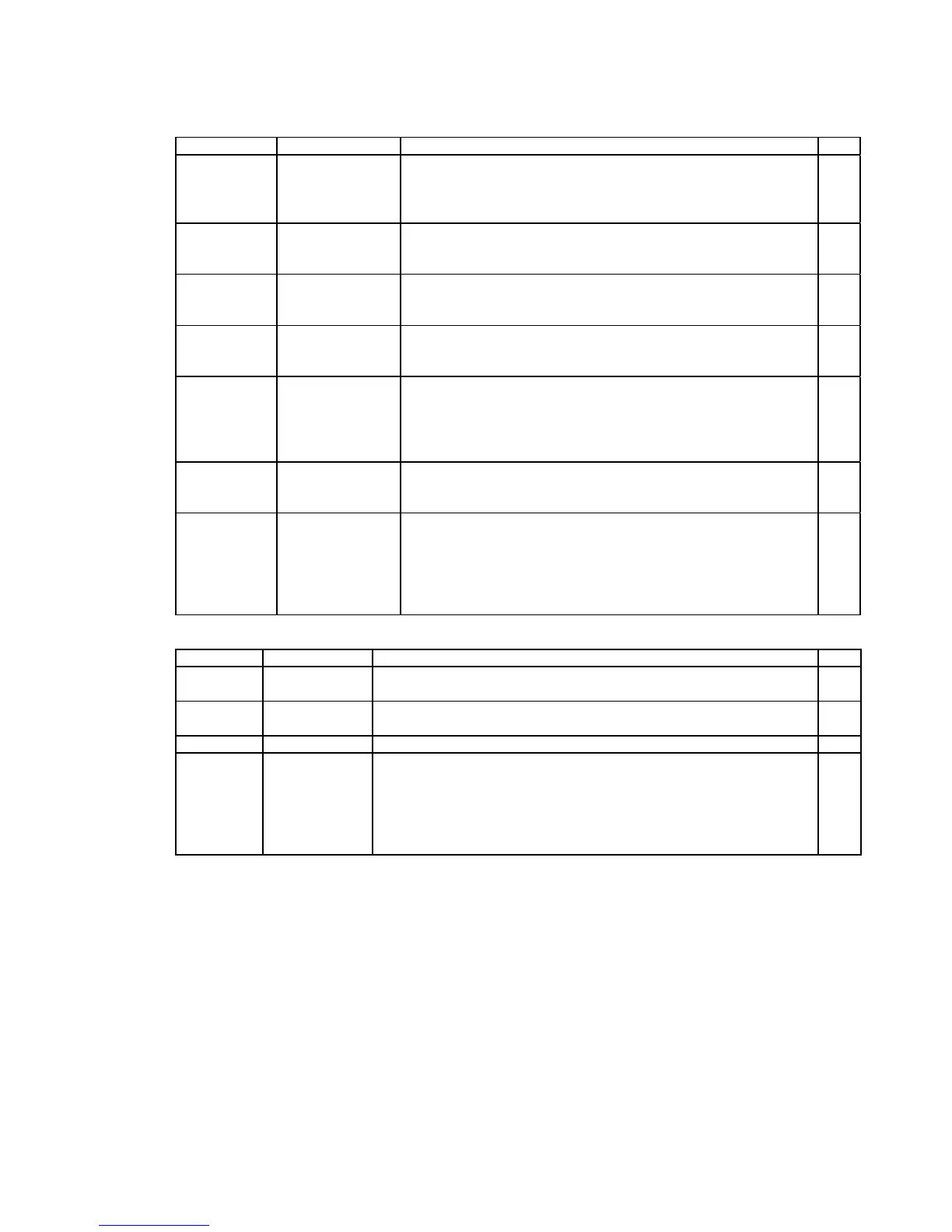

12P terminal block (TM 12P )

P in No. S ignal name Function

+

•|

-

R E ADY

(OUTP UT)

R eady P ower

The terminals used for ready power for prep. relay. When

there is not any error such as open phas e, Operation S top,

output over current, and thermal overload, the terminals work,

etc. while the power switch is on, the terminals function.

*1

+

•|

-

G AS (INP UT)

S olenoid Valve

C ontrol

The terminals used for controlling the gas solenoid valve by

external signals. (If the terminals are s hort-circuited, the gas

valve will open.)

*2

+

•|

-

E XT1 (INPUT)

E xtra Input

S ignal 1

The terminals used for special specifications. These terminals

should not be used for normal use.

*2

+

•|

-

E XT2 (INPUT)

E xtra Input

S ignal 2

The terminals used for special specifications. These terminals

should not be used for normal use.

*2

+

•|

-

S T OP (INPUT )

Operation S top

To stop welding externally. R elease the wiring between two

terminals to run Operation S top. Welding machine is s topped

by running Operation S top. C lose the terminals after turning

off the torch switch to restart welding. To avoid accidental

restart, use of a Push lock Turn reset switch is suggested.

*2

+

•|

-

WC R (OUTP UT)

C urrent

Detection

C ontact Output of welding current relay used for detection of

welding current. The contacts close while welding current is

flowing.

*3

+

•|

-

Abnormal water

pressure

detection

(INP UT)

In case of there is the abnormal water pressure detection

relay in the cooling unit, which is like a pressure s witch,

remove the jumper wire on the terminal and connect the relay

contact. (C lose: normal Open: abnormal) T hen torch key in

the front panel is set “Water“ and contact is “Open” make E -

510 light up.

*3

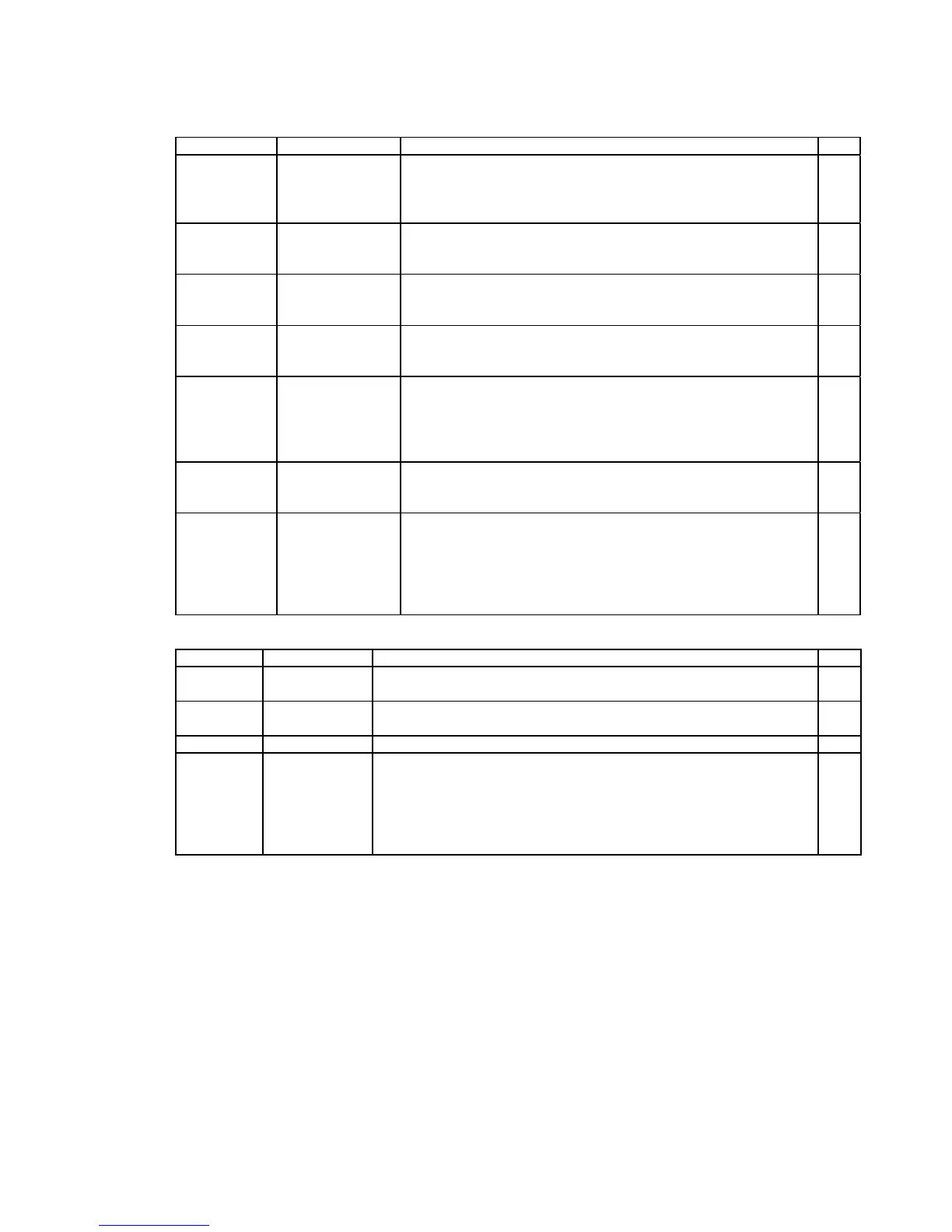

6P terminal block (T M 6P )

P in No. S ignal name Function

+

•|

-

AMME TE R Terminals for connecting an ammeter.

Use the ammeter (400A/60mV , part number: 4403-057).

+

•|

-

VOLT ME TE R T erminals for connecting a voltmeter.

Use the voltmeter (full scale 100V , part number: 4401-016).

*4

Unused

Negative

Terminal for

Direct

Detection of

Voltage

When using a power cable that is more than 30 m long, direct

connection of a direct detection wire of the base metal (-) to the

wire feeder is recommended, but it is imposs ible to connect to the

wire feeder due to jig, use the terminal block inside this welding

power source. R efer to S ection 10.2.1 (12) “Arc V oltage Direct

Detection ON/OF F S election” for details of direct detection.

P recaution for connection with terminals on the terminal block

The wires from the terminal blocks should be twisted for each signals to avoid accidental operation.

Take care that the wires form the terminal blocks do not cross other signal wires from other welding

power source.

*1 E quivalent circuit is as the figure shown right. Maximum capacity of TR is 80V , 100mA. When

connecting such as relay to two terminals, do not exceed 80% of the maximum capacity of T R .

(F igure 1)

*2 E quivalent circuit is as the figure shown right. C onnect allowable contacts (10mA or more) to two

terminals. (Figure 2)

*3 R ating of the provided relay contacts is 125V AC, 0.5A, 30V DC , 1A. Do not exceed 80% of the

rating of the provided relay contacts.

1 2

3 6

4 6

5 6

7 8

9 10

11 12

1 2

3 4

5

6

Loading...

Loading...