9. WELDING PREPARATION (continued)

(2) Example Welding Conditions of Downward Welding

Plate

thickness

t(in [mm])

Shape of

joint weld

Welding

current

(A)

Welding

voltage

(V)

Welding

speed

(ft [cm]/min)

Remarks

0.091 [2.3] butt 100 22-23 2.3 [70] Back bead appearance is good.

0.126 [3.2] fillet 100 21-22 2.3 [70]

Leg length: 0.157-0.197in

[4 - 5mm],

Throat depth: 0.098in [2.5mm]

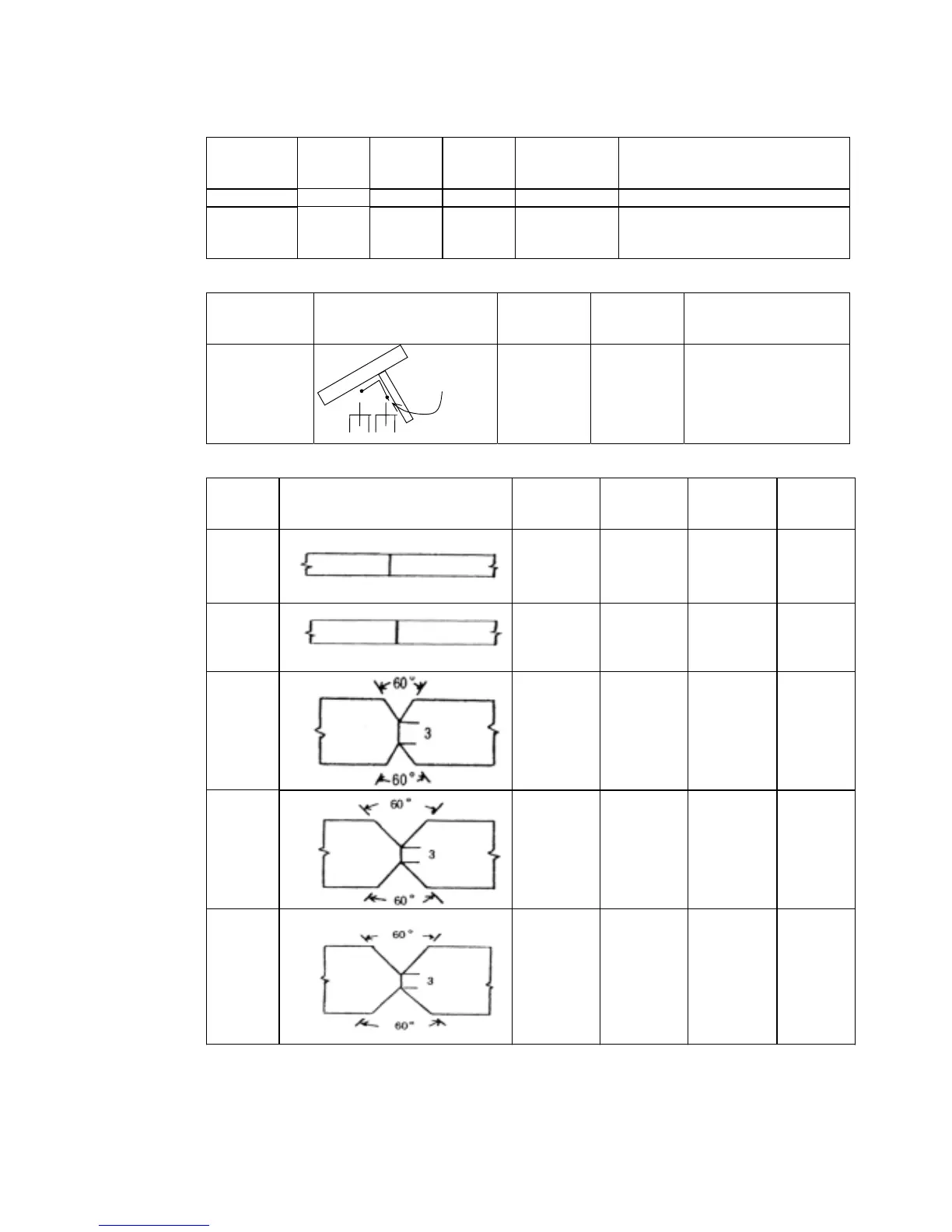

(3) Example Welding Conditions of Upward Welding

Plate

thickness

t (in [mm])

Shape of joint weld

Welding

current

(A)

Welding

voltage

(V)

Remarks

0.472

[12]

100-110 20-21

Weaving

Leg length: 0.394in

[10.0mm]

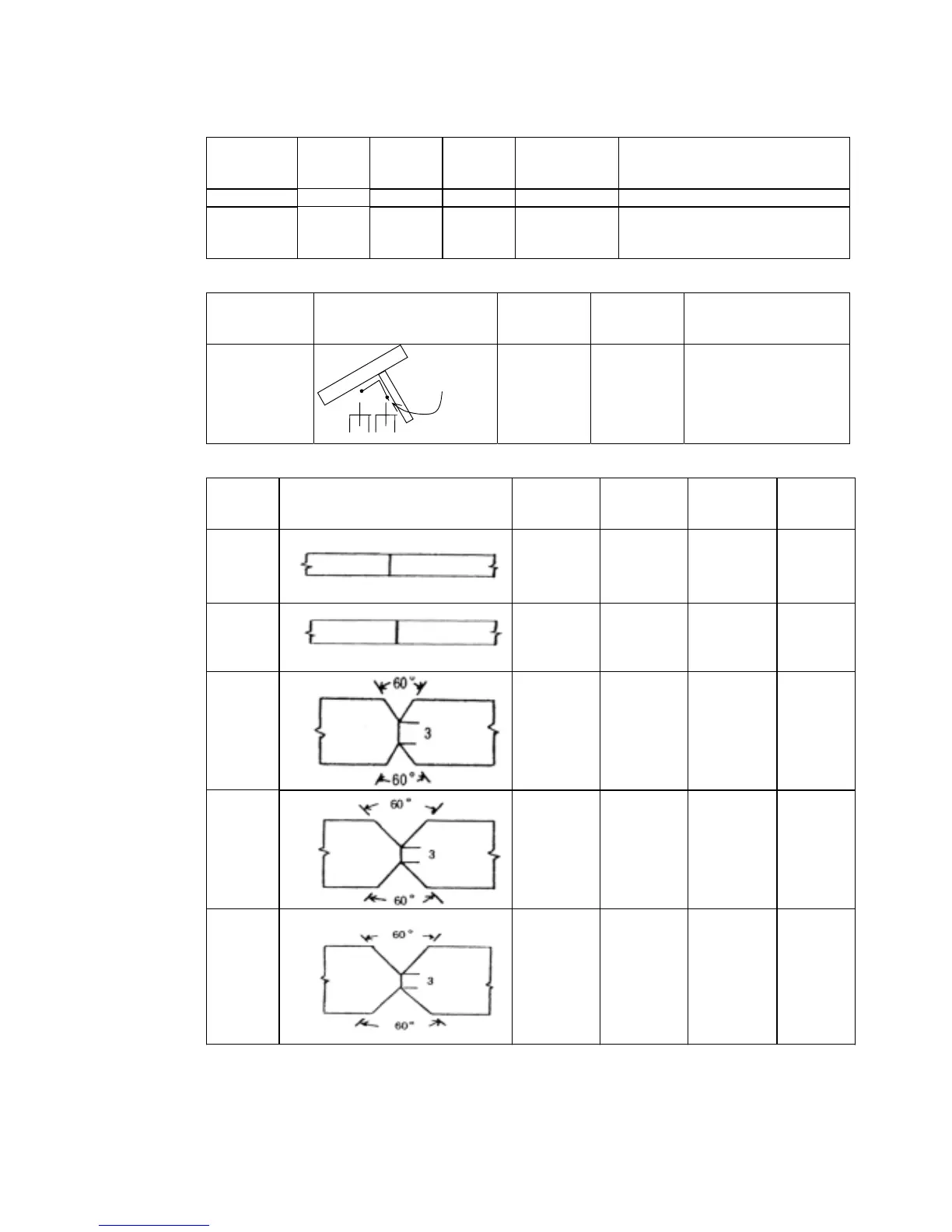

(4) Both Side Welding Conditions of (Semi-automatic)

Plate

thickness

(in [mm])

Groove shape

Number of

layers

Welding

current

(A)

Welding

voltage

(V)

Welding

speed

(ft [cm]/min)

0.236

[6.0]

1

2

170

180

25-26

26-27

1.0 [30]

1.0 [30]

0.354

[9.0]

1

2

270

290

29-30

30-31

1.0 [30]

1.0 [30]

0.472

[12.0]

1

2

280

330

30-31

33-34

1.3 [40]

1.3 [40]

0.748

[19.0]

Front 1

Front 2

Rear 1

Rear 2

300

300

340

280

31-32

31-32

32-33

30-31

1.5 [45]

1.5 [45]

1.5 [45]

1.5 [45]

0.984

[25.0]

Front 1

Front 2

Front 3

Rear 1

Rear 2

Rear 3

300

320

320

340

320

320

31-32

32-33

32-33

32-33

32-33

32-33

1.5 [45]

1.5 [45]

1.5 [45]

1.5 [45]

1.5 [45]

1.5 [45]

Stop at both ends

Loading...

Loading...