No. P10355

|20|

9.

WELDING PREPARATION (continued)

9.4 Welding Conditions

When setting to the improper welding conditions, the following troubles will occur.

Cause Trouble

Wire extension is too long.

¥

Long Arc length

¥

Wide bead width

¥

Poor shield

Wire extension is too short.

¥

Short arc length

¥

Easy generation of spatter

Arc voltage is too high.

¥

Long arc length

¥

Wide bead width

¥

Shallow penetration and flat bead

Arc voltage is too low.

¥

Stick to base metal and easy generation of spatter

¥

Narrow bead width

¥

Deep penetration and high excess metal

Welding current is too high.

¥

Wide bead width

¥

Deep penetration and high excess metal

Welding speed is too fast.

¥

Narrow bead width

¥

Shallow penetration and low excess metal

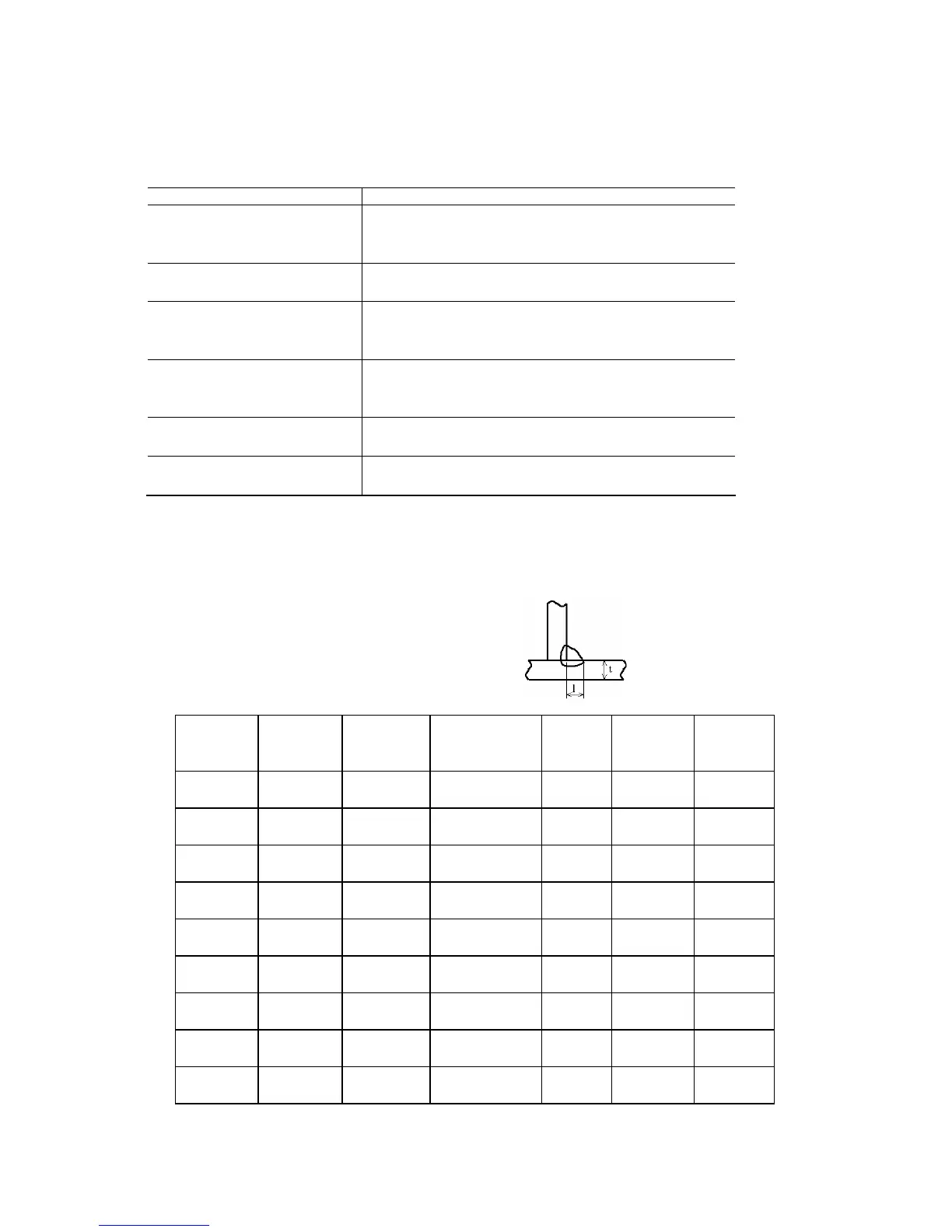

The data in the tables below is only for reference. Please find the optimum welding conditions for

weldment shape and welding position.

9.4.1 Example CO

2

Welding Conditions

(1) Example Welding Conditions of Horizontal Fillet

Plate

thickness

t (in [mm])

Leg length

l (in [mm])

Wire

diameter

(in [mm]

)

Welding

current

(A)

Arc

voltage

(V)

Welding

speed

(ft [cm]/min)

CO

2

gas

flow rate

(gal [Ɛ]/min)

0.047 [1.2] 0.098-0.118

(2.5

|

3.0)

0.035

[0.9

|

1.0]

70

|

100 18

|

19

1.6-2.0

[50

|

60]

2.6-4.0

[10

|

15]

0.063 [1.6] 0.098-0.118

(2.5

|

3.0)

0.035-0.045

[0.9

|

1.2]

90

|

120 18

|

20

1.6-2.0

[50

|

60]

2.6-4.0

[10

|

15]

0.079 [2.0] 0.118-0.138

(3.0

|

3.5)

0.035-0.045

[0.9

|

1.2]

100

|

130 19

|

20

1.6-2.0

[50

|

60]

4.0-5.3

[15

|

20]

0.091 [2.3] 0.118-0.138

(3.0

|

3.5)

0.035-0.045

[0.9

|

1.2]

120

|

140 19

|

21

1.6-2.0

[50

|

60]

4.0-5.3

[15

|

20]

0.126 [3.2] 0.118-0.157

(3.0

|

4.0)

0.035-0.045

[0.9

|

1.2]

130

|

170 19

|

21

1.5-1.8

[45

|

55]

4.0-5.3

[15

|

20]

0.177 [4.5] 0.157-0.177

(4.0

|

4.5)

0.045 [1.2]

190

|

230 22

|

24

1.5-1.8

[45

|

55]

4.0-5.3

[15

|

20]

0.236 [6.0] 0.197-0.236

(5.0

|

6.0)

0.045 [1.2]

250

|

280 26

|

29

1.3-1.6

[40

|

50]

4.0-5.3

[15

|

20]

0.354 [9.0] 0.236-0.276

(6.0

|

7.0)

0.045 [1.2]

280

|

300 29

|

32

1.1-1.3

[35

|

40]

4.0-5.3

[15

|

20]

0.472 [12.0] 0.276-0.315

(7.0

|

8.0)

0.045 [1.2]

300

|

340 32

|

34

1.0-1.1

[30

|

35]

5.3-6.6

[20

|

25]

Loading...

Loading...