No. P10355

|76 |

14. SPECIFICATIONS (continued)

ƔInitial Values and Setting Range of Parameter

Initial value Setting range

Pre-flow time 0.1 second 0 – 10 seconds

Current 20 A 20 – 400 A

Voltage 10 V 10 – 45 V

E

Initial condition

E

Main condition

E

Crater filler condition

Fine adjustment of voltage

0 -30 – 30

Post-flow time 0.4 second 0 – 10 seconds

Arc spot time 3 seconds 0.1 – 10 seconds

Arc characteristic 0 -10 – 10

Wave frequency 3 Hz 0.5 – 32 Hz

JOB MEMORY numbers 1 1 – 100

ƔFunction

Initial value Setting item

Crater OFF

OFF / ON (without pulse) / ON

i

with pulse

j

/ SPOT

Welding method DC pulse DC pulse / DC wave pulse (optional )

Wire/Gas

MILD STEEL

MAG

MILD STEEL CO

2

/MILD STEEL CORED

CO

2

/STAINLESS CORED CO

2

/MILD STEEL

CORED MAG/STAINLESS STEEL MIG/

ALUMINUM PURE MIG/ ALUMINUM MIG

Wire diameter

0.045in

(1.2mm)

0.030/0.035/0.040/0.045(3/64)/[1/16]in

(0.8/0.9/1.0/1.2/1.6mm)

Initial current OFF ON/OFF

Adjustment of welding voltage SYNERGIC SYNERGIC/INDIVIDUAL

Penetration control OFF ON/OFF

ƔInternal Functions (Function

j

<Refer to Section 10.2.1, “Using of internal functions >

Initial value Setting range

F1 Fine adjustment of anti-stick (burnback) time* 0 -50(0.50 second down) – 50(0.50 second up)

F2

Fine adjustment of anti-stick (burnback)

voltage*

0.0 -9.9 – 9.9 V

F3 Fine adjustment of slow-down speed* 0.0 -1.0 – 1.0 m/min.

F4 Selection of automatic/semi-automatic OFF ON(AUTOMATIC)/OFF(SEMI-AUTOMATIC)

F5 External command 10VMAX OFF ON(VALID)/OFF(INVALID)

F6 Setting of up-slope time* 0.0 0 – 10.0 seconds

F7 Setting of down-slope time* 0.0 0 – 10.0 seconds

F8 Result display holding time 20 5 – 60 seconds

F9

Selection of scale plate of analog remote

control

350 200/350

F10 Feed motor load current error detection level 70 20 – 150 %

F11

Fine adjustment of Job Memory Fine

Adjustment

OFF

n mi

VALID

j

/

neei

INVALID

j

F12 Arc voltage direct detection ON/OFF selection OFF

n m i

DIRECT

j

/

neei

TERMINAL

j

F13 Fine adjustment of pulse peak current* 0 -150 A – 150 A

F14 Fine adjustment of pulse peak time* 0 -1.5 (ms) – 1.5 (ms)

F15 Fine adjustment of base current* 0 -60 A – 60 A

F16 Fine adjustment of L pulse peak current* 0 -150 A – 150 A

F17 Fine adjustment of L pulse peak time* 0 -1.5 (ms) – 1.5 (ms)

F18 Fine adjustment of L pulse base current* 0 -60 A – 60 A

F19 Turbo Start ON/OFF selection ON

n mi

VALID

j

/

neei

INVALID

j

F20 Keypad tone ON/OFF selection ON

n mi

VALID

j

/

neei

INVALID

j

*Welding conditions which can be preset to a JOB MEMORY number.

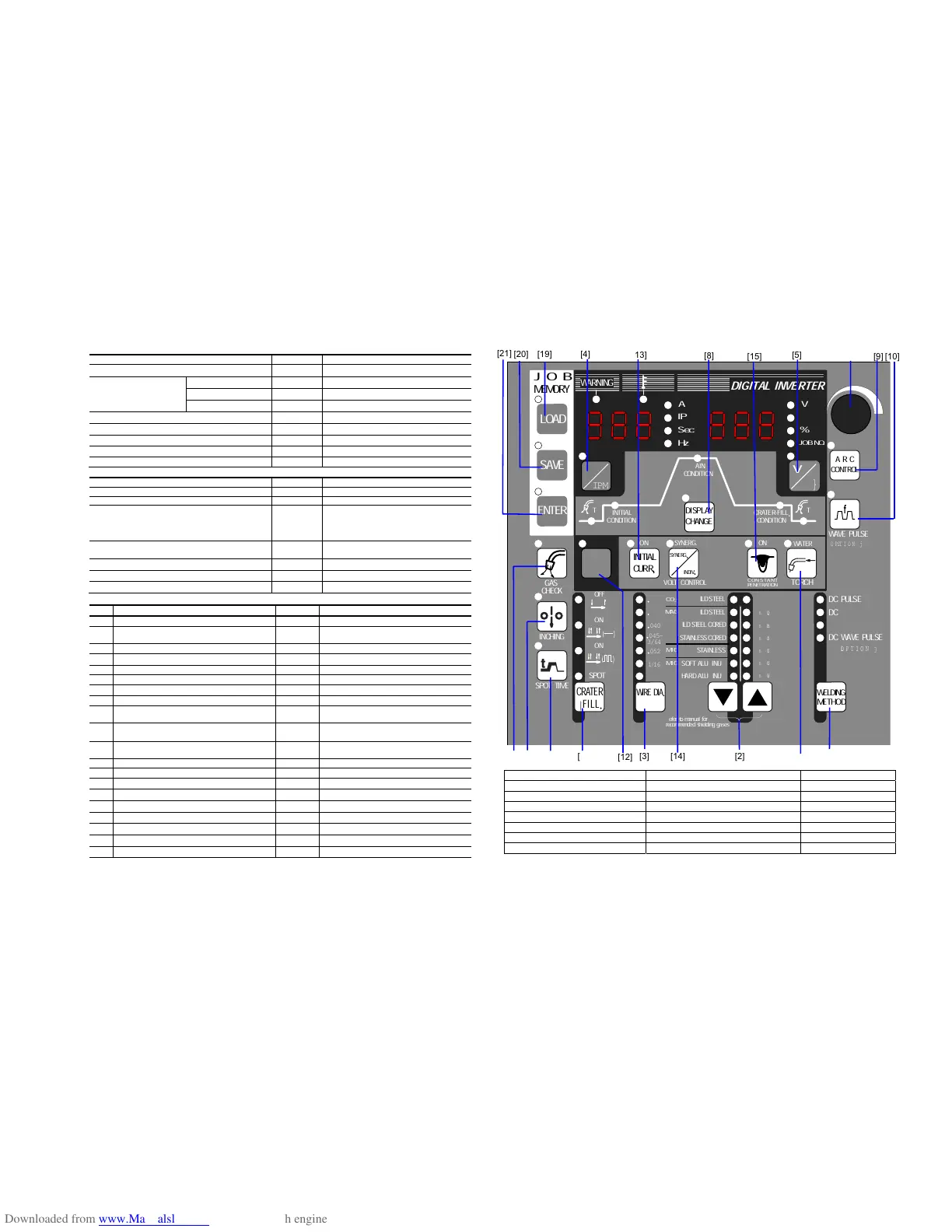

Front Panel

[1] WELDING METHOD key [9] ARC CONTROL key [17] GAS CHECK key

[2] WIRE/GAS selector keys [10] WAVE PULSE key (optional) [18] INCHING key

[3] WIRE DIA (inch) key [11] SPOT TIME key [19] LOAD key

[4] IPM selector key [12] F (FUNCTION) key [20] SAVE key

[5] V/r selector key

[13] INITIAL CURR. key [21] ENTER key

[6] Parameter adjusting knob [14] VOLT. CONTROL key

[7] CRATER-FILL key [15] CONSTANT PENETRATION key

[8] DISPLAY CHANGE key [16] TORCH key

( )

( )

.

030

(inch)

e

n o

n o

.

035

n oP

}

WARNING

LOAD

SAVE

ENTER

J OB

MEMORY

Sec

JOBNO.

V

}

A

IPM

A

IPM

V

T1 T2

MAIN

CONDITION

INITIAL

CONDITION

DISPLAY

CHANGE

VOLT. CONTROL

ON

INITIAL

CURR.

SYNERG.

SYNERG.

INDIV.

SPOT TIME

GAS

CHECK

INCHING

OFF

ON

SPOT

ON

CONSTANT

PENETRATION

WELDING

METHOD

WIREDIA

MILDSTEEL

MILDSTEEL

STAINLESS

SOFTALUMINUM

HARDALUMINUM

CO

2

STAINLESSCORED

MAG

MIG

MIG

TORCH

%

Hz

f

DCPULSE

DC WAVEPULSE

DC

WAVEPULSE

ON

n oQ

n oR

n oS

n oT

CRATER-FILL

CONDITION

CRATER

|

FILL

iO P T I O N j

iO P T I O N j

ARC

CONTROL

n oU

n oV

WATER

DIGITAL INVERTER

.

045-

3/64

.

040

.

052

1

/

16

MILDSTEELCORED

Refer tomanual for

recommended shielding gases

[21]

[20]

[19] [4]

[13]

[8]

[5]

[9]

[10]

[2][14][3]

[12]

[7]

[11]

[18] [16]

[1]

[17]

[6][15]

Loading...

Loading...