No. P10355

|

77

|

( )

14. SPECIFICATIONS (continued)

QUICK MANUAL

Refer to Section 10.1, “Basic Settings”and Section 10.2, “Applied Settings”.

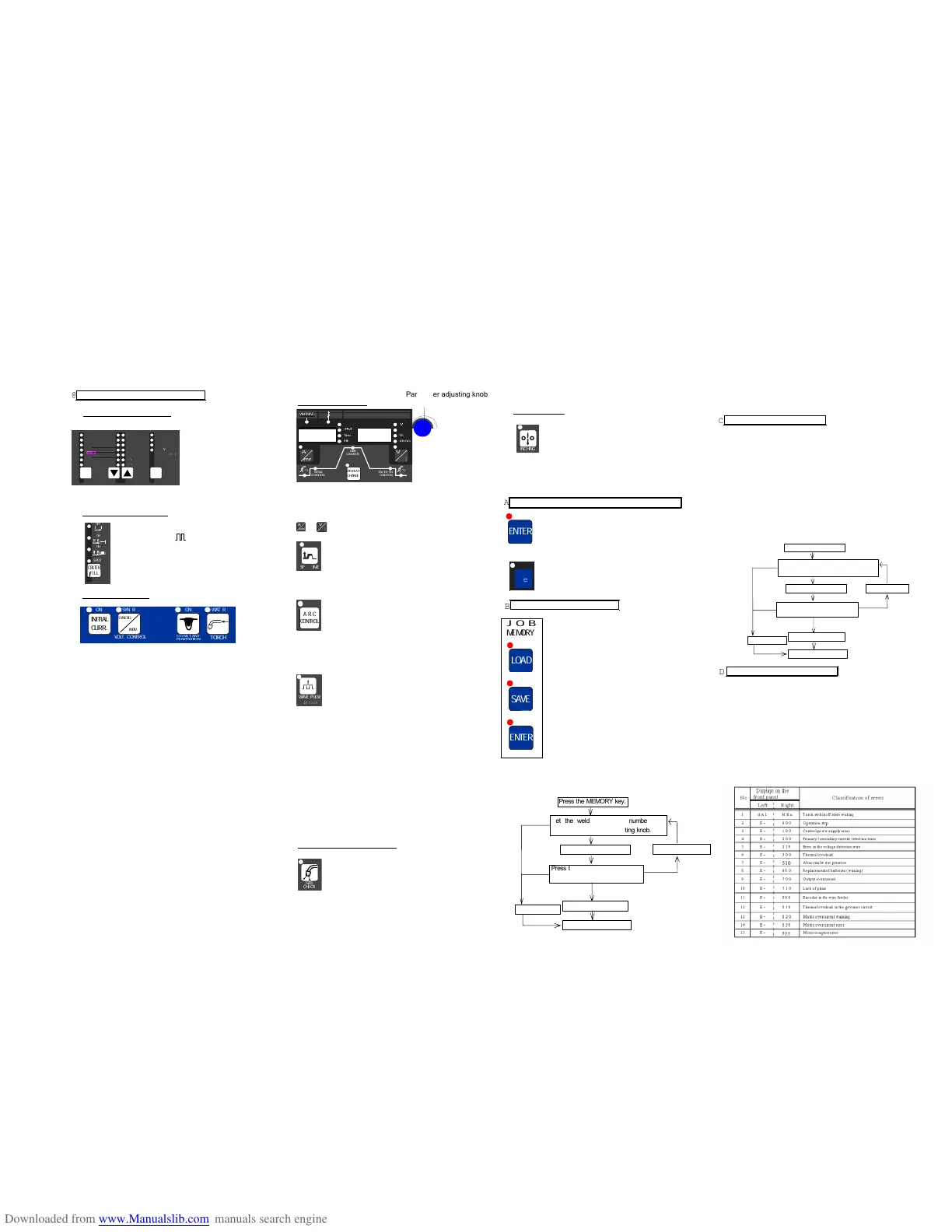

Before Using the Welding Power Source

1. Settings of Welding Method

Set a welding method,

wire/ shield gas, then

wire diameter by using

the WELDING METHOD

key, the WIR/GAS

selector keys, and the

WIRE DIA. (mm) key

respectively.

2. Settings of Crater/Arc Spot

Use the CRATER-FILL key to select

OFF/ON(-)/ON( )/ SPOT.

3. Settings of Functions

xFor using INITIAL CURRENT, press the INITIAL

CURR. key to set the function to “ON”.

[ON]: INITIAL CURR. lamp is on.

[OFF]: INITIAL CURR. lamp is off.

xFor controlling voltage in the SYNERG. way, select

“SYNERG.” by pressing the VOLT.CONTROL key.

[SYNERGIC]: VOLT. CONTROL lamp is on.

[INDIVIDUAL]: VOLT. CONTROL lamp is off.

xFor activating a CONSTANT PENETRATION function,

set the function to “ON”.

[ON]: CONTANT PENETRATION lamp is on.

[OFF]: CONSTANT PENETRATION lamp is off.

xFor using a water-cooled torch, select “WATER” by

pressing the TORCH key, then run cooling water.

[WATER]: TORCH lamp is on.

[AIR]: TORCH lamp is off.

4. Settings of Parameter

Use the DISPLAY CHANGE key to select the parameter

you want to set, then adjust it while turning the parameter

adjusting knob.

When changing the parameter unit in the display, use the

or selector key.

When adjusting SPOT TIME, press the SPOT

TIME key, then set SPOT TIME while turning

the parameter adjusting knob.

[ON]: SPOT TIME lamp is on.

[OFF]: SPOT TIME lamp is off.

To adjust the desired arc characteristic

(HARD/SOFT), after turning on the ARC

CONTROL lamp by pressing the ARC

CONTROL key, set the level of the arc

characteristic.

[ON]: ARC CONTROL lamp is on.

[OFF]: ARC CONTROL lamp is off.

When the welding method is wave pulse, to

obtain the desired bead appearance after

turning on the WAVE PULSE lamp by

pressing the WAVE PULSE key, set the wave

pulse while turning the parameter adjusting

knob.

[ON]: WAVE PULSE lamp is on.

[OFF]: WAVE PULSE lamp is off.

NOTE:

xTurning the parameter adjusting knob clockwise

increases the parameter. To decrease the parameter,

turn the parameter adjusting knob counter-

clockwise.

xThere may be unavailable parameters in some

crater settings and function settings. Refer to

Section 10, “OPERATION” for details.

5. Checking the Rate of Gas Flow

Open the discharge valve of the gas cylinder,

press the GAS CHECK key to check the rate

of gas flow. After performing GAS CHECK,

stop the gas flow by pressing the GAS

CHECK key.

6. Inching the Wire

After pressurizing the wire mounted on the

wire feeder using the pressure roll, feed the

wire up to the end of the torch while using the

INCHING key. When pressing the INCHING

key again, the wire feeding stops.

Now you have completed the preparations that are required to

start welding. Press the torch switch to start welding.

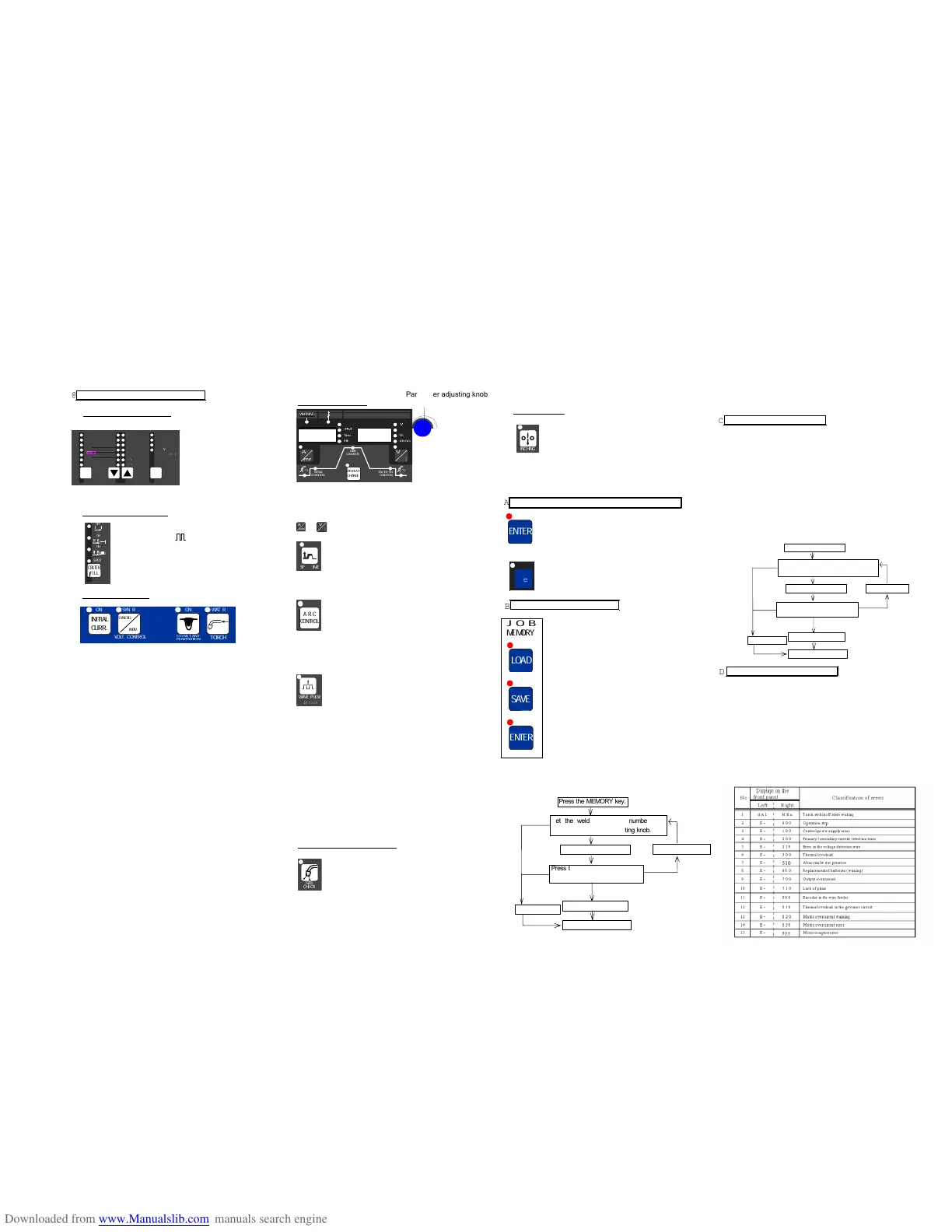

Protecting the Keys and Releasing the Key Protection

xProtecting of the keys

Hold down the ENTER key + the F key at a

time for a few seconds. The F lamp starts

blinking. Blinking of the F lamp means the

welding machine is in the key protection mode.

xReleasing the key protection

Hold down the ENTER key + the F key at a

time for a few seconds. When the F lamp turns

off, the key protection function is released.

Presetting the Welding Conditions

1) Pressing the SAVE key enters the save

mode. The preset welding condition

number is displayed in the right display

and the welding current is displayed in

the left display.

2) Preset the welding conditions to the

desired numbers 0 - 100 while turning

the parameter adjusting knob. When “---

“ is displayed in the left display, the

number you selected is available. When

“---” is not displayed in the left display,

the number you selected is unavailable.

In this case, select another number.

Otherwise, the welding conditions preset

to the number are erased and

overwritten with the welding conditions

you newly set.

3) Press the ENTER key to check the

parameter preset to the number.

4) When pressing the ENTER key again,

the welding conditions are set.

Loading the Welding Conditions

1) Pressing the LOAD key enter the load mode. The

preset welding condition number is displayed in the

right display and the welding current is displayed in the

left display.

2) Preset the welding conditions to the desired numbers 0

– 100 while turning the parameter adjusting knob.

When “---“ is displayed in the left display, no welding

conditions are preset to the number you selected.

3) Press the ENTER key to check for the parameter

preset to the number.

4) When pressing the ENTER key again, the welding

conditions preset to the welding condition number are

retrieved.

Settings of the (Internal) Functions

1) When holding down the F key for a few seconds, the

function mode is activated. The function number blinks

in the left display, the function status is displayed in

the right display.

2) Set the function number while turning the parameter

adjusting knob.

3) When pressing the F key, the function number lights

up, then the function status blinks.

4) Set the function status while turning the parameter

adjusting knob.

5) To cancel the function mode, hold down the F key for

a few minutes.

Loading...

Loading...