No. P10355

|23|

9. WELDING PREPARATION (continued)

-

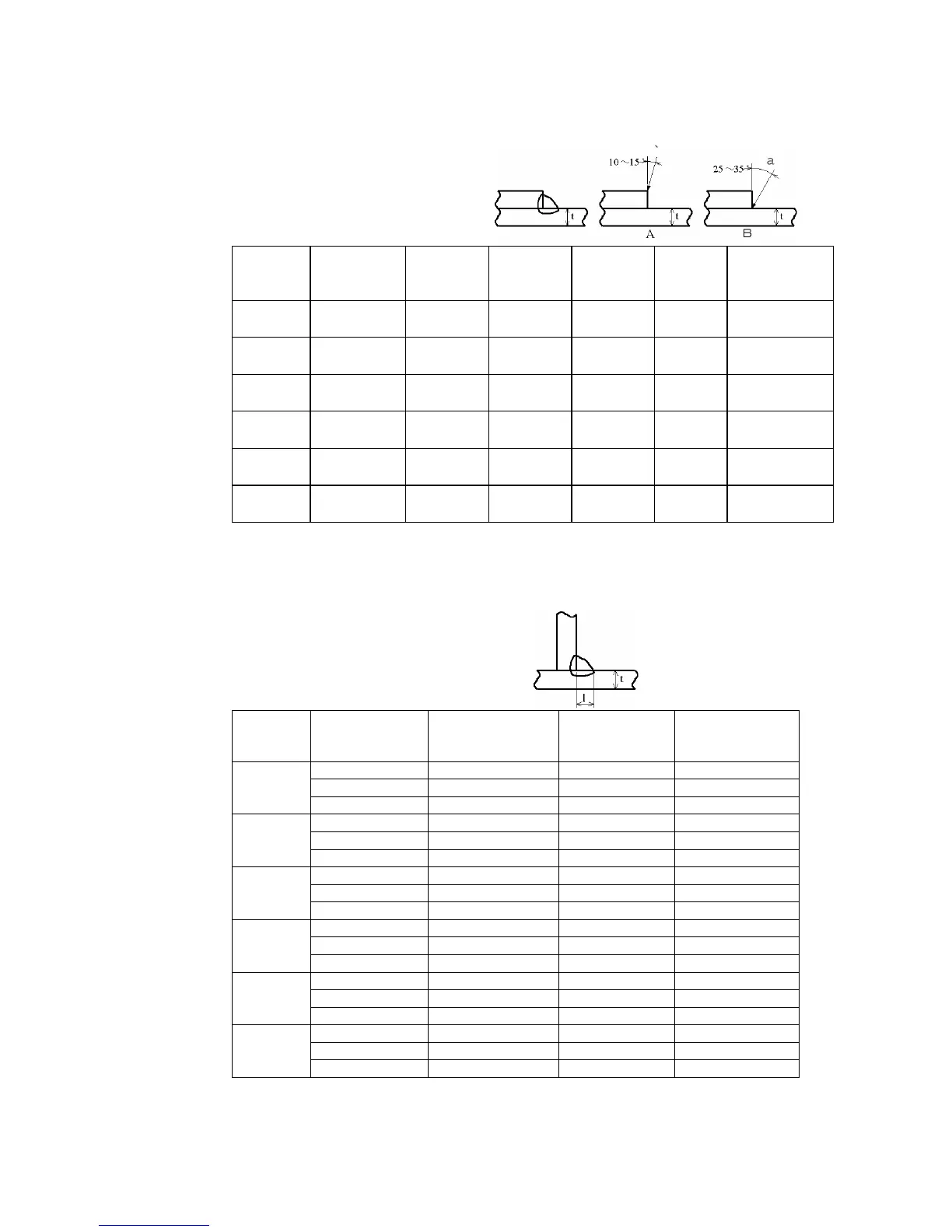

Example Welding Conditions of Lap Fillet

Plate

Thickness

t

(in [mm])

Wire

diameter

(in [mm]

)

Welding

current

(A)

Welding

voltage

(V)

Welding

speed

(ft [cm]/min)

Mark

position

CO

2

gas

flow rate

(gal [Ɛ]/min)

0.047

[1.2]

0.035

[0.9

|

1.0]

80

|

100 18

|

19

1.5-1.8

[45

|

55]

A 2.6-4.0

[10

|

15]

0.063

[1.6]

0.035-0.045

[0.9

|

1.2]

100

|

120 18

|

20

1.5-1.8

[45

|

55]

A 2.6-4.0

[10

|

15]

0.079

[2.0]

0.035-0.045

[1.0

|

1.2]

100

|

130 18

|

20

1.5-1.8

[45

|

55]

A or B 4.0-5.3

[15

|

20]

0.091

[2.3]

0.035-0.045

[1.0

|

1.2]

120

|

140 19

|

21

1.5-1.6

[45

|

50]

B 4.0-5.3

[15

|

20]

0.126

[3.2]

0.035-0.045

[1.0

|

1.2]

130

|

160 19

|

22

1.5-1.6

[45

|

50]

B 4.0-5.3

[15

|

20]

0.177

[4.5]

0.045

[1.2]

150

|

200 21

|

24

1.3-1.5

[40

|

45]

B 4.0-5.3

[15

|

20]

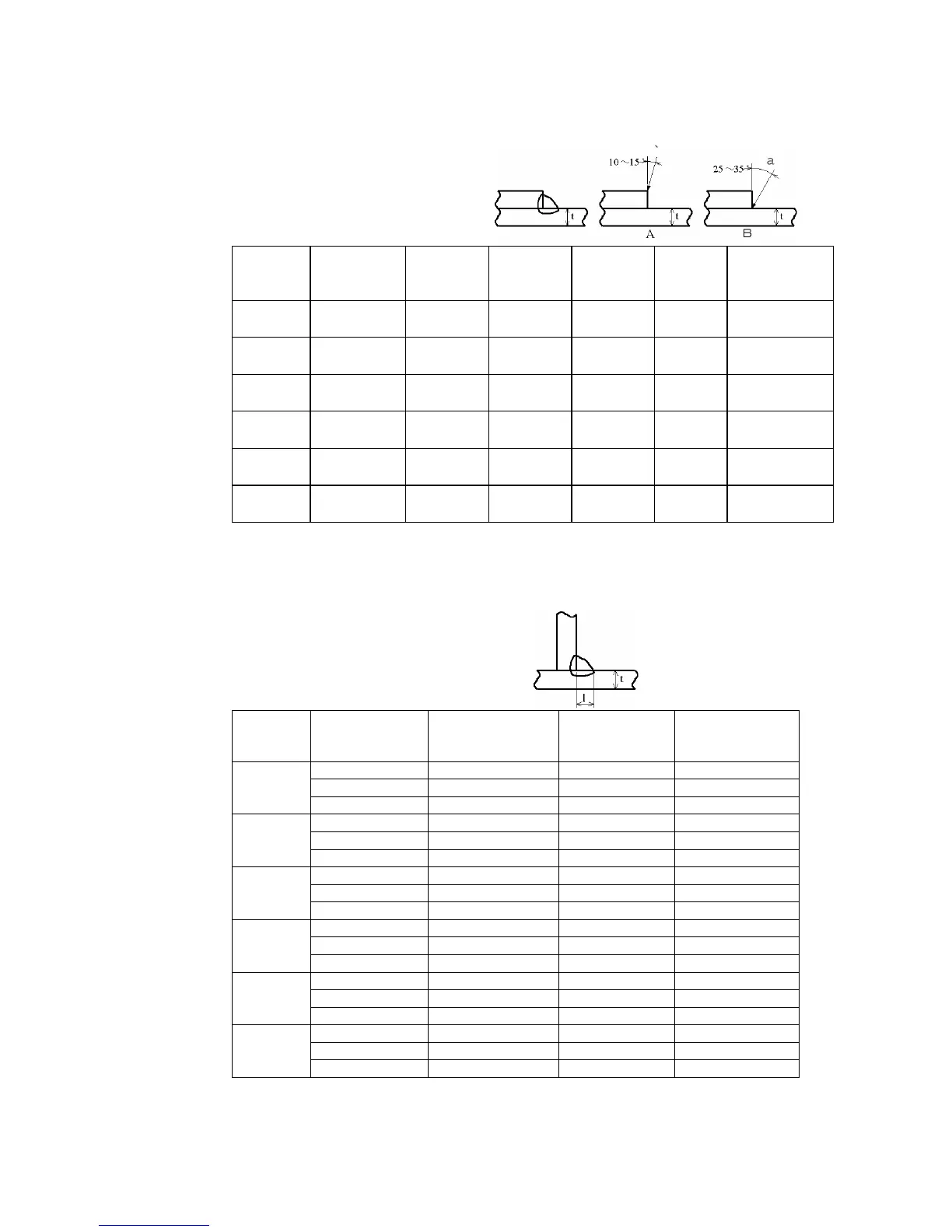

9.4.2 Example Welding Conditions of Wire CO

2

with Flux

(1)Example Welding Conditions of Horizontal Fillet

Leg

length

Ɛ

(in [mm])

Wire diameter

(in [mm]

)

Welding current

(A)

Arc voltage

(V)

Welding speed

(ft [cm]/min)

0.045 [1.2] 250 27 1.6 [50]

0.052 [1.4] 330 29 3.3 [100]

0.16

[4]

1/16 [1.6] 350 31 3.4 [105]

0.045 [1.2] 270 29 1.6 [50]

0.052 [1.4] 330 30 3.0 [90]

0.20

[5]

1/16 [1.6] 370 33 3.0 [90]

0.045 [1.2] 270 29 1.5 [45]

0.052 [1.4] 330 31 2.6 [80]

0.24

[6]

1/16 [1.6] 380 34 2.6 [80]

0.045 [1.2] 280 30 1.3 [40]

0.052 [1.4] 350 32 1.6 [50]

0.28

[7]

1/16 [1.6] 380 34 2.1 [65]

0.045 [1.2] 300 31 1.0 [30]

0.052 [1.4] 350 33 1.5 [45]

0.32

[8]

1/16 [1.6] 380 34 1.7 [52]

0.045 [1.2] 320 32 1.0 [30]

0.052 [1.4] 350 34 1.3 [40]

0.35

[9]

1/16 [1.6] 380 34 1.3 [40]

`

a

Loading...

Loading...