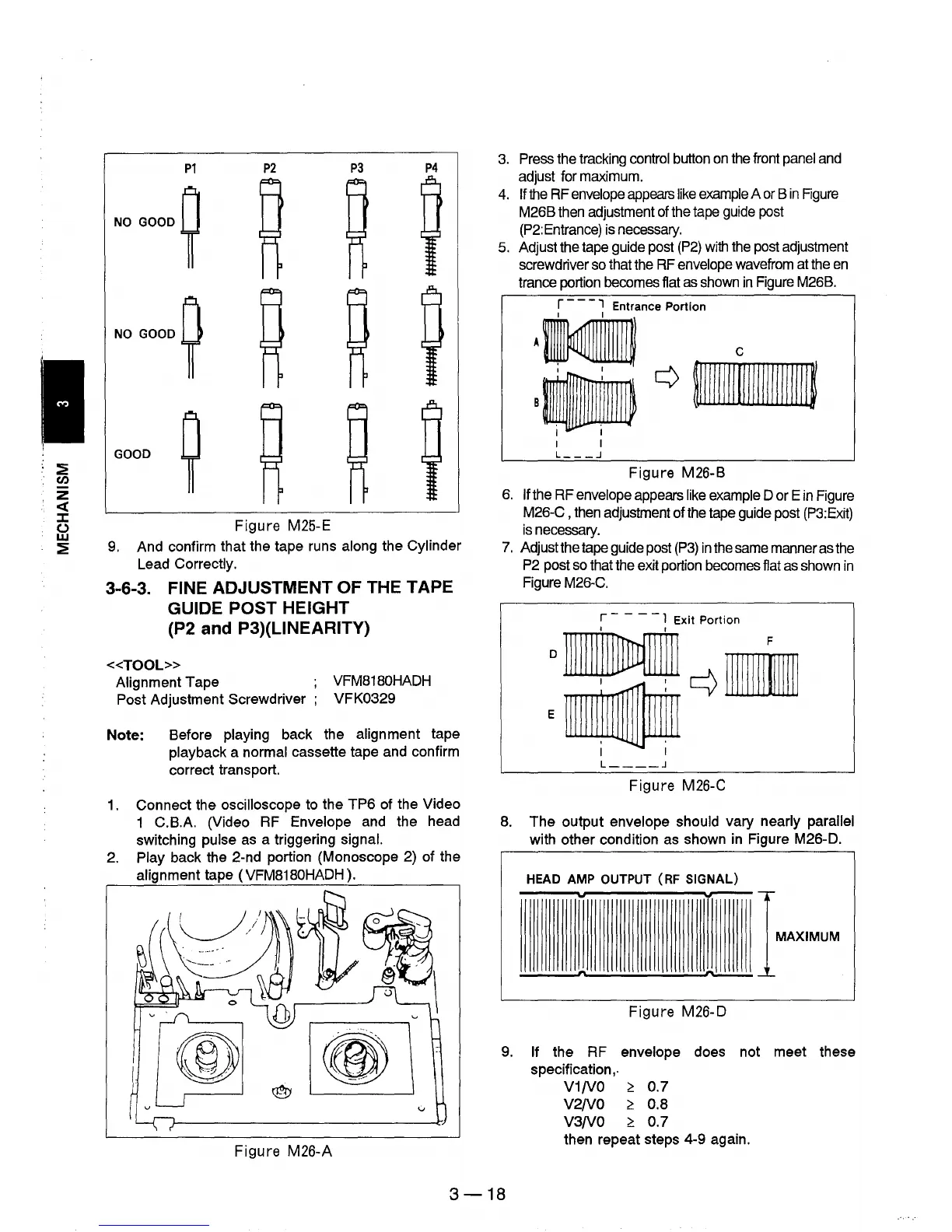

P1

P2

P3

P4

NO

GOOD

~

NO GOOD

~

GOOD

~

Figure

M25-E

9.

And confirm that the tape runs along the Cylinder

Lead Correctly.

3-6-3. FINE ADJUSTMENT OF THE TAPE

GUIDE POST HEIGHT

(P2 and P3)(UNEARITY)

«TOOL»

Alignment Tape

Post Adjustment Screwdriver ;

VFM8180HADH

VFK0329

Note:

Before playing back the alignment tape

playback a normal cassette tape and confirm

correct transport.

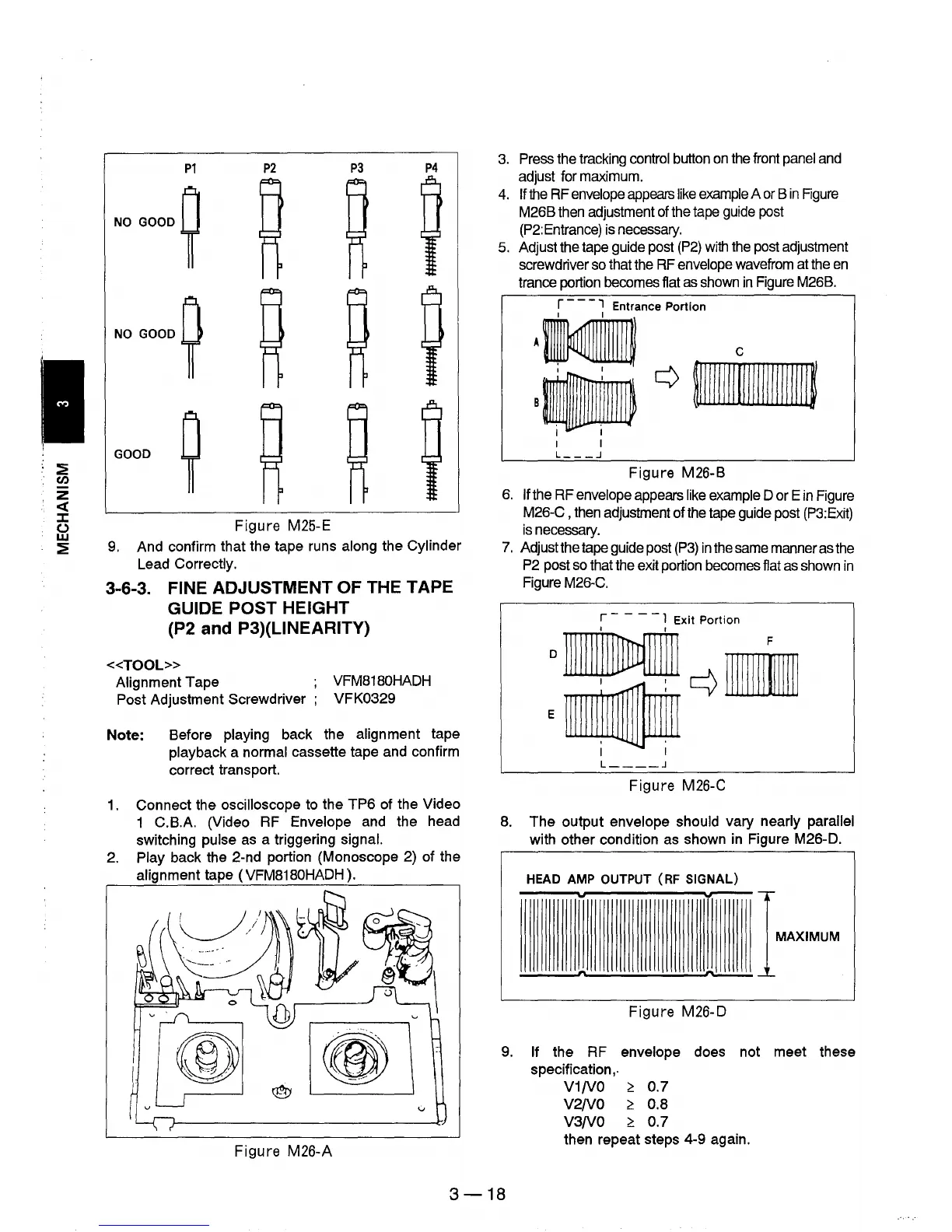

1.

Connect the oscilloscope to the

TP6

of the Video

1 C.B.A. (Video RF Envelope and the head

switching

pulse as a triggering signal.

2. Play back the 2-nd portion (Monoscope 2) of the

alignment tape (VFM8180HADH).

Figure

M26-A

3.

Press the tracking control button

on

the front

panel

and

adjust for maximum.

4.

If

the

RF

envelope

appears

like

example

A

or

B

in

Rgure

M26B then adjustment of the tape

guide

post

(P2:Entrance) is necessary.

5. Adjust the tape guide post

(P2)

with

the post adjustment

screwdriver so that the

RF

envelope wavefrom at the

en

trance portion becomes flat

as

shown

in

Figure M26B.

r - -

-,

Entrance Portion

I I

I I

I I

L

___

.J

Figure

M26-B

6.

If the RF envelope appears

like

example D or E

in

Figure

M26-C , then adjustment of the tape guide post

(P3:Exit)

is

necessary.

7.

Adjust the tape guide post

(P3)

in

the same manner as the

P2

post

so

that the exit portion becomes flat

as

shown

in

Figure M26-C.

r - - -

-1

Exit Portion

o

1111111'IIMffil

r-1\

IJlIF

E"~

I I

L

____

.J

Figure

M26-C

8.

The

output envelope should vary nearly parallel

with other condition as shown in Figure M26-D.

HEAD

AMP

OUTPUT

(RF

SIGNAL)

..

...--

IMAXIMUM

~

__

~n

~

Figure

M26-D

9.

If the RF envelope does not meet these

specification

"

V1/V0

~

0.7

V2/V0

~

0.8

V3/V0

~

0.7

then repeat steps 4-9 again.

3-18

Loading...

Loading...