Function Parameters 9-45

AC10 Inverter

FA20 Integration time I (s)

FA21 Differential time D (s)

FA22 PID sampling period (s)

Increasing proportion gain, decreasing integration time and increasing differential time can

increase the dynamic response of PID closed-loop system. But if P is too high, I is too low or D

is too high, system may be unstable.

PID adjusting period is set by FA22. It affects PID adjusting speed.

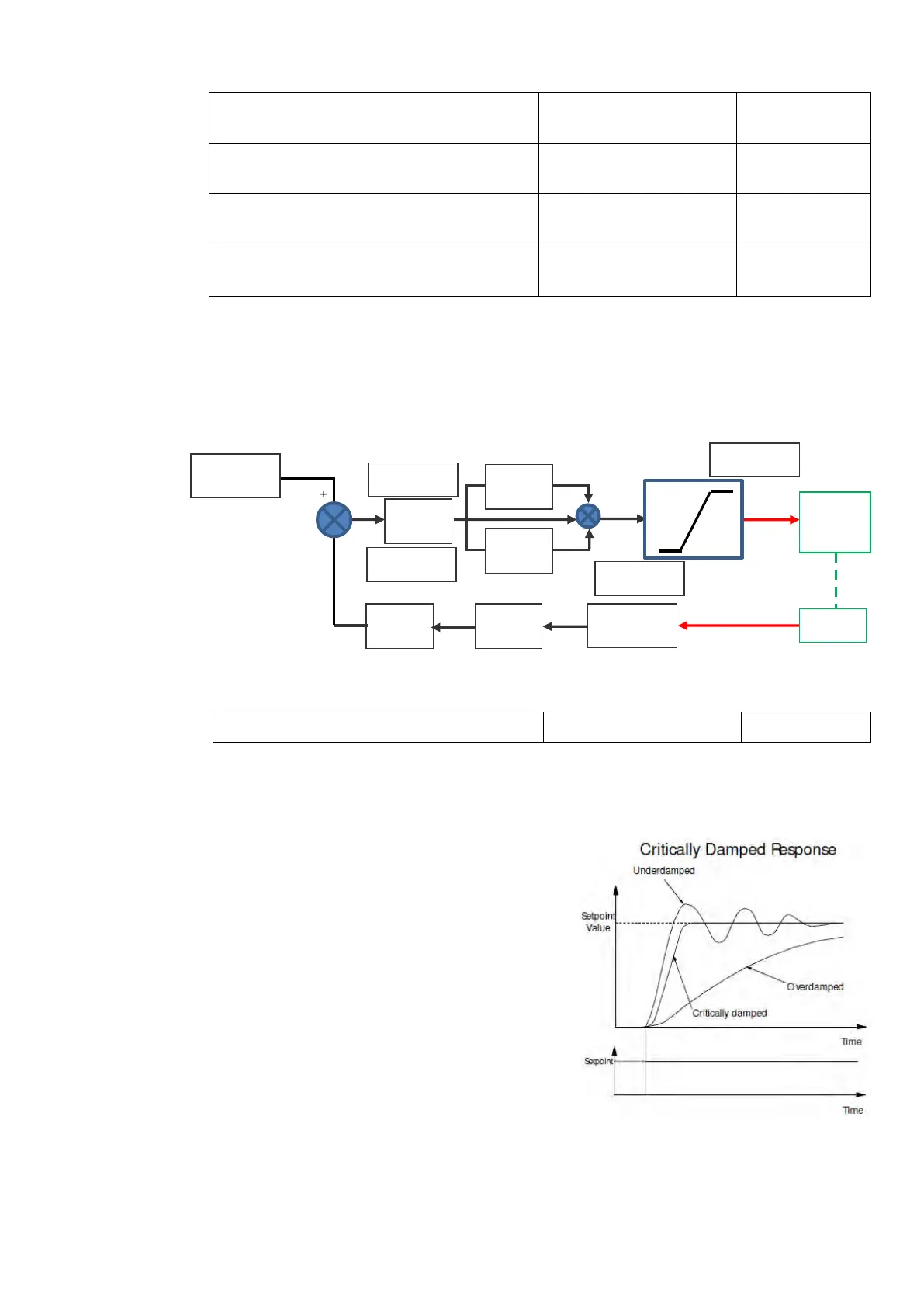

The following is PID block diagram.

FA29, PID dead time has two functions. First, setting dead time can restrain PID adjustor

oscillation. The greater this value is, the lighter PID adjustor oscillation is. But if the value of

FA29 is too high, PID adjusting precision will decrease. For example: when FA29=2.0 and

FA04=70, PID adjusting will not be valid during the feedback value from 68 to 72.

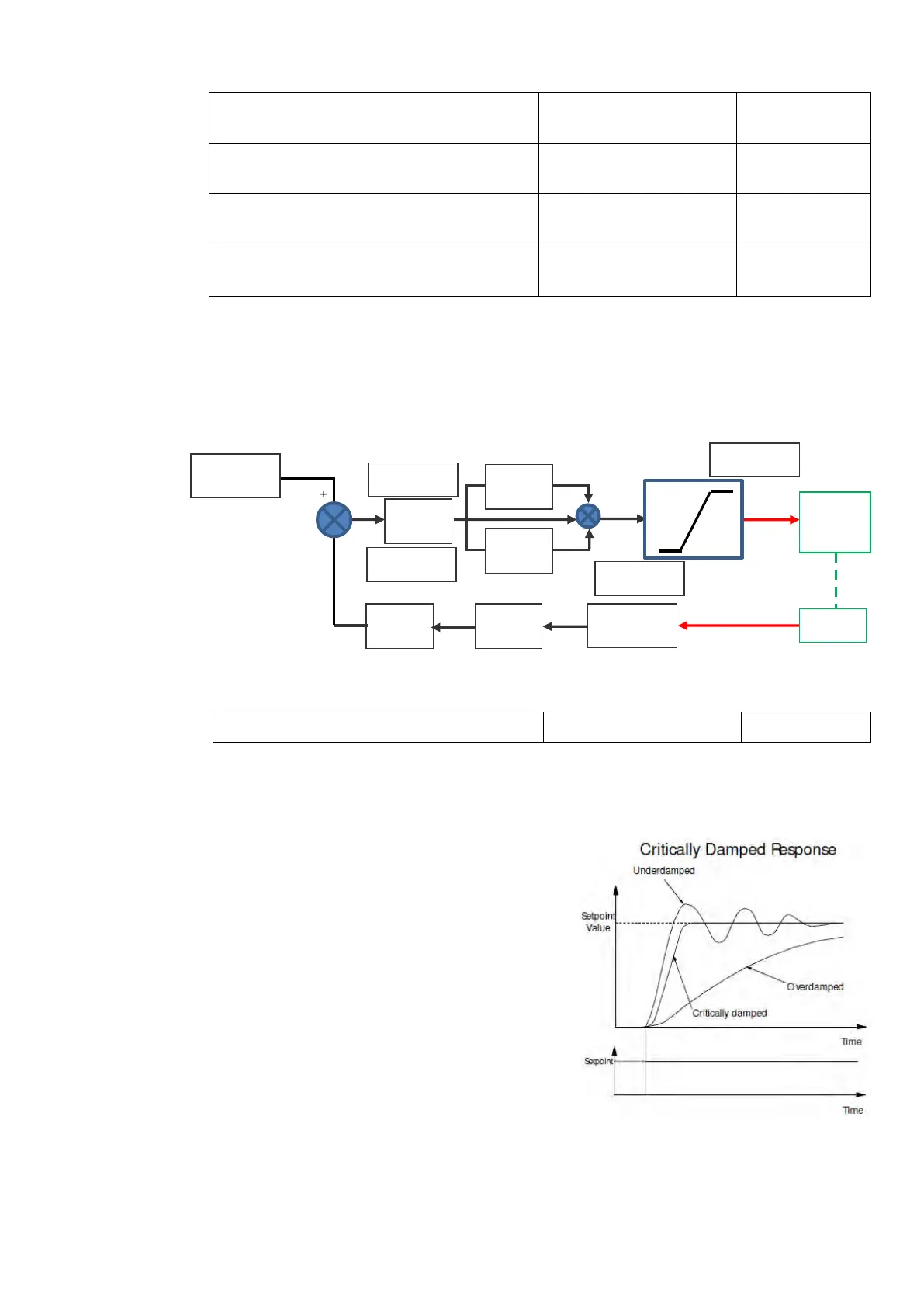

You should try to achieve a critically damped

response which allows the mechanics to track as

precisely as possible a step change on the

setpoint.

• In underdamped systems, the output

oscillates and the settling time increases.

• Critically damped systems have no

overshoot or oscillations. They reach the

setpoint within the desired response time.

• Overdamped systems do not oscillate but

do not reach the setpoint within the desired

response time.

Note: For most applications, derivative gain is not used and is left at its default value of 0.0S

Derivative gain can improve response in some dancer tension controlled systems, particularly those

systems with high inertia dancers which need an instantaneous response to overcome the weight of

the dancer roll. For loadcell controlled tension systems, derivative gain is almost never used.

Object

Gain

Filter

Reference

Feedback

Loading...

Loading...