15192 Triton Lane

Huntington Beach, CA 92649

Office Tel: 714-892-3400

Hotline Tel: 714-891-6533

www.ppedm.com

This document is the property of PPedm Corp. and contains proprietary and/or patented information and may not be reproduced in

part or in whole without the express written permission of the company. Perfect Point logo, Perfect Point

TM

and E-Drill

®

are

trademarks of PPedm, Corp. US and worldwide patents pending.

head and a short distance into the stem (or pin) of the aircraft fastener. During cutting,

a closed loop de-ionized water system is used as a Dielectric Fluid and circulated

throughout the head of the device, in such a manner that the fastener and surrounding

airframe do not heat up and are cold to the touch immediately after cutting.

The depth of cutting is controlled automatically, such that a thin wall remains holding

the fastener head in place. The fastener head may then easily be severed by a sharp

tap with a hammer and hand punch. When the device is positioned correctly the

airframe is not damaged in any way, and the temperature rise in the airframe around

the hole is insignificant. Due to the depth of the cut, the fastener stem has no remnant

burr which may damage the hole in the airframe as the stem is driven out.

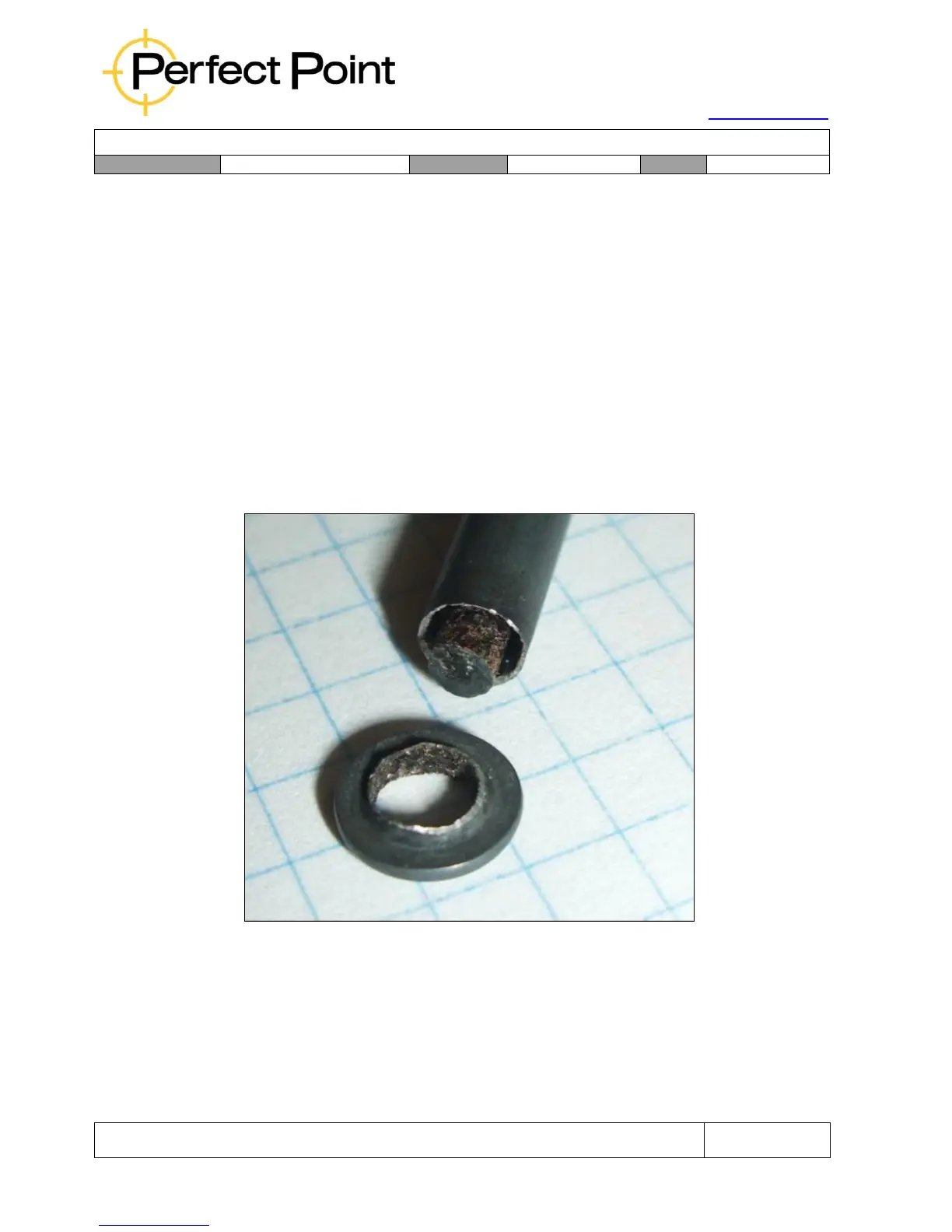

The photograph below shows a severed fastener with the groove and the fractured

thin wall. Note that the cut is concentric with the stem; the wall thickness is uniform

around the pin, the cut ends just below the head, and the fastener stem is burr free.

Loading...

Loading...