This document is the property of PPedm Corp. and contains proprietary and/or patented information and may not be reproduced in

part or in whole without the express written permission of the company. Perfect Point logo, Perfect Point

TM

and E-Drill

®

are

trademarks of PPedm, Corp. US and worldwide patents pending.

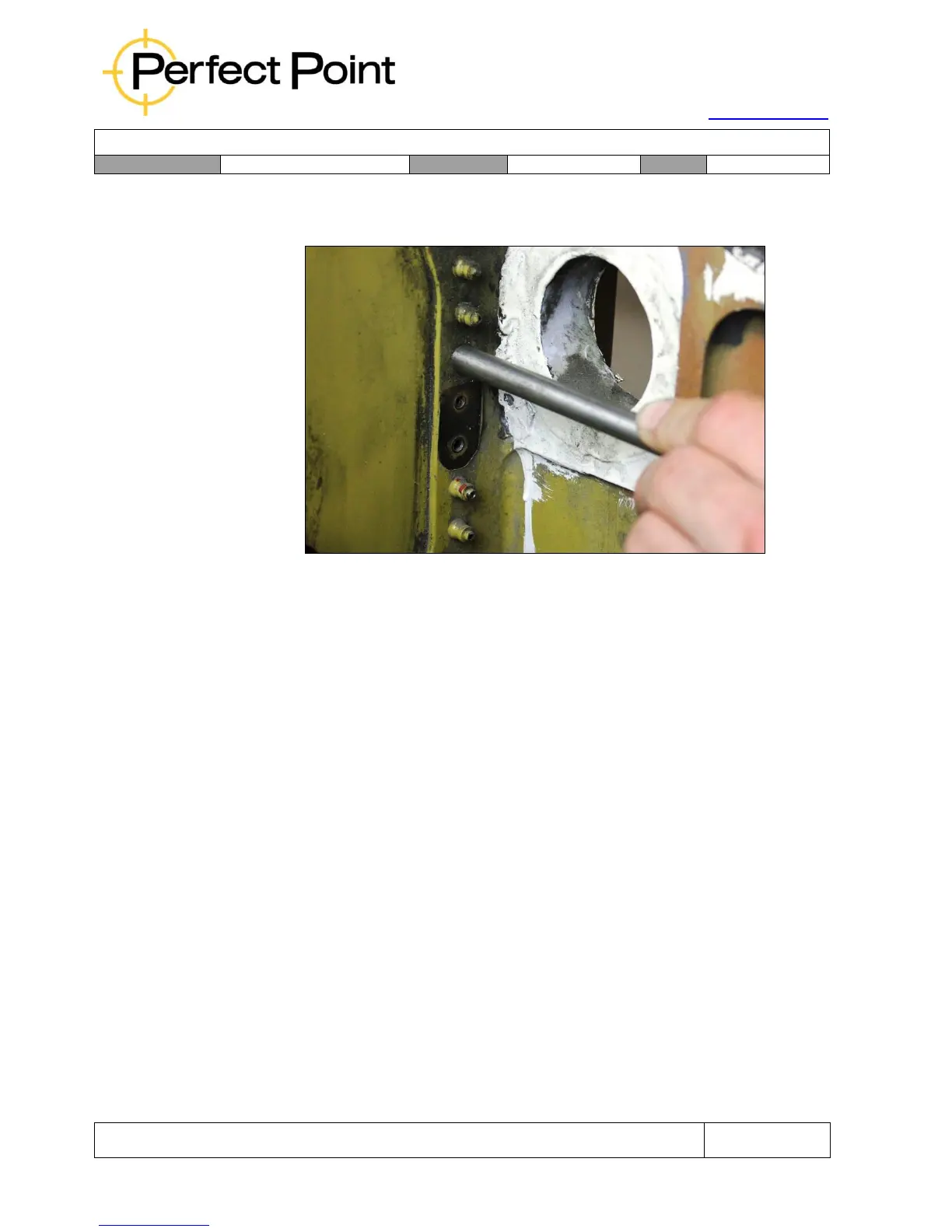

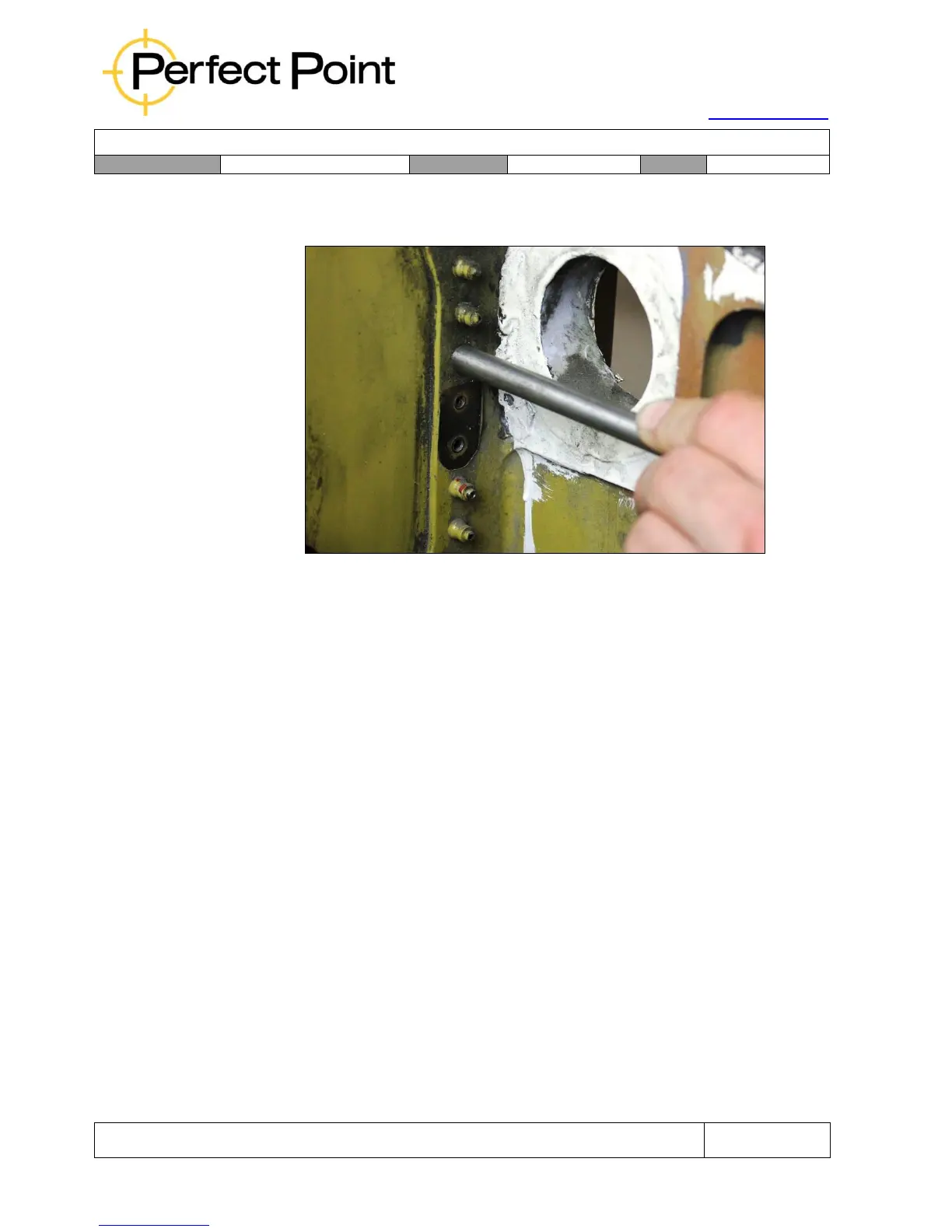

E)

After cutting the collar drive the shank through to release the collar and

remove the pin.

2.7

Removal of Blind Core-Bolt Fasteners (Cherry, OSI etc.):

Some fasteners have a separate core bolt, removal of which will facilitate

disassembly, or a much simpler drilling operation. Monogram OSI fasteners are an

example of the former, while Cherry and Huck Unimatic blind fasteners are an

example of the latter. Other types of fasteners may also benefit from similar

techniques. Both OSI and Blind fasteners have specific entries in the Touch-Screen

Display fastener library, but both have specific techniques, listed below:

2.7.1

Monogram OSI Fasteners:

OSI-bolts, as they are known, rarely need to be removed. An OSI can easily

be removed by removing the head off the core-bolt, then driving out the core

and the tail, and then pulling out the body. Typically, an electrode one size

down from the fastener step size is used. For example a 1/4” OSI fastener

core-bolt would be removed using a 3/16” electrode.

2.7.2

Monogram Composi-Lok Fasteners:

Composi-Lok fasteners are typically difficult to remove with their two-piece

construction. These can be removed using either a EG E-Drill or a CG E-Drill

and the plus series of electrodes. These were specifically designed to both

accommodate the slightly larger shank diameter of these fasteners and to

significantly reduce the removal strike force required with the punch buddy. A

standard size Punch Buddy is used when removing the fasteners. Note, when

removing flush head Composi-Lok fasteners it is recommended to use a VHL

Loading...

Loading...