B)

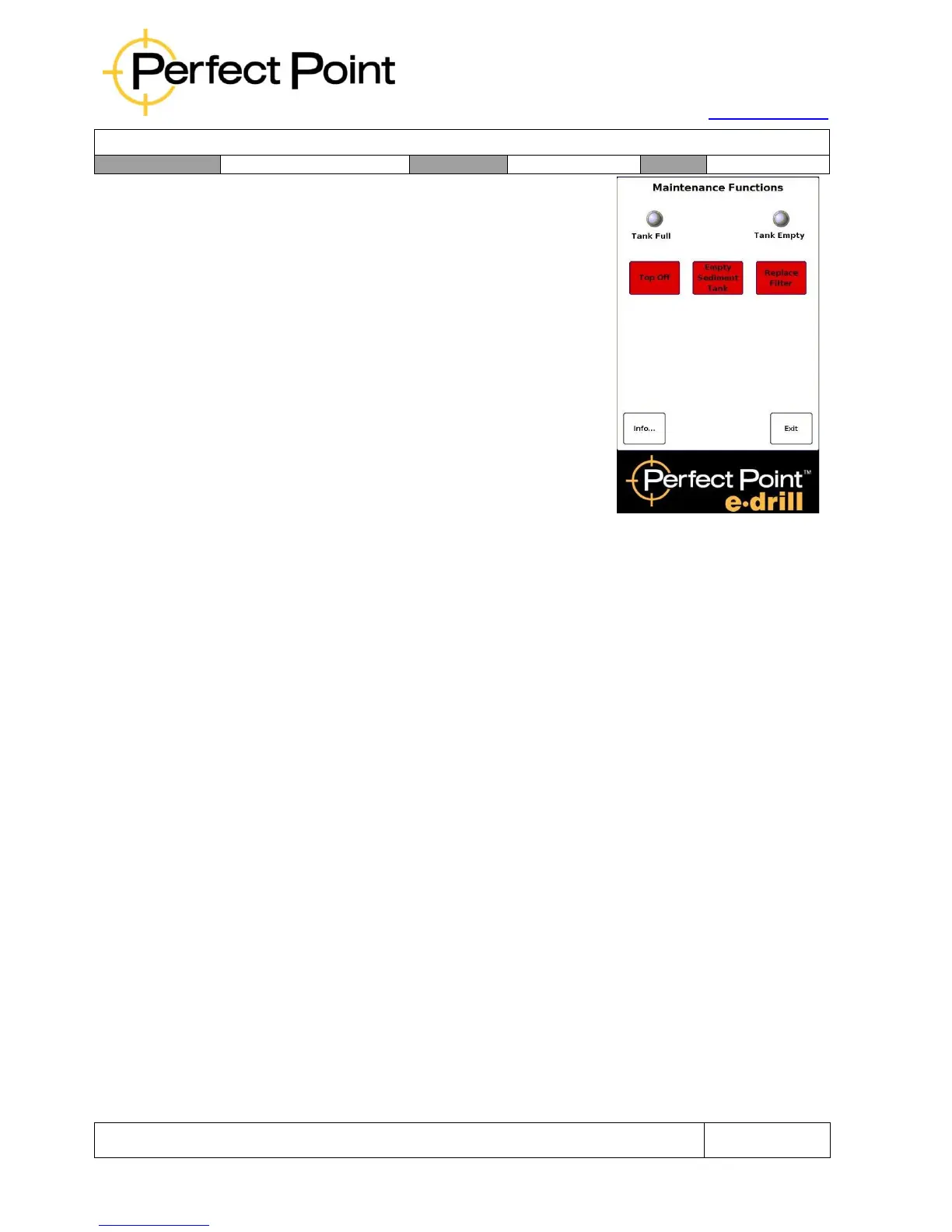

Empty the system by pressing the Empty

Sediment Tank button in the Maintenance

Screen of the Touch-Screen Display. The

button will change color to green and the

system will automatically pump out sufficient

water for the Sediment Bowl to be removed

and cleaned. The pump will terminate

automatically when sufficient water has

been removed.

Once the pump is started a “pop-up” screen

will appear prompting the user to reset the

sediment tank counter. This function allows

the operator to determine if the sediment

tank is truly to be emptied, or if other system

bleed/charge procedures are being

performed (see Section 3.7) and allows the

cut cycle counter to be reset or ignored as appropriate. Press the YES

button to proceed.

C)

Loosen the Dielectric Lock-Bolt on the frame to the right of the entire Filter

Assembly. Rotate the assembly until nearly horizontal (see photograph at the

end of this section) and retighten the Lock-Bolt.

D)

Using the Filter Bowl Wrench provided with the system, loosen the Sediment

Bowl (bowl on the right, marked Sediment). Use caution; there will be some

residual water in the bowl. Unthread by hand; carefully remove the bowl

without touching the pick-up tube or fragile level sensor assembly to its right.

Dump sediment and clean out the Sediment Bowl with a clean, lint free shop

towel. Do not attempt to clean the Level Sensor Sleeve.

E)

Prior to reassembly, inspect the bowl to ensure the large O-ring seal is clean

and undamaged, properly lubricated and seated before reinstalling. Hand-

thread the tank onto the Filter Cap Assembly, taking care not to unseat the

O-ring or touch the center pick-up tube or the level sensor assembly. Use the

Filter Bowl Wrench provided with the system to lightly tighten the bowl.

Return the Bowl Assembly to vertical position and tighten the Dielectric Filter

Assembly Lock Bolt.

F)

Ensure that the end of the drain/bleed tube is submerged in water, then

recharge system using Dielectric Top-Off button. Ensure that water is being

drawn into the system by watching for movement of air-bubbles when the

procedure is started. If water is not being drawn into the system, it is

likely that the O-ring is incorrectly installed. Re-tilt the assembly and

Loading...

Loading...