2:5

D

E

F

G

C

B

A

C

B

A

Preparations

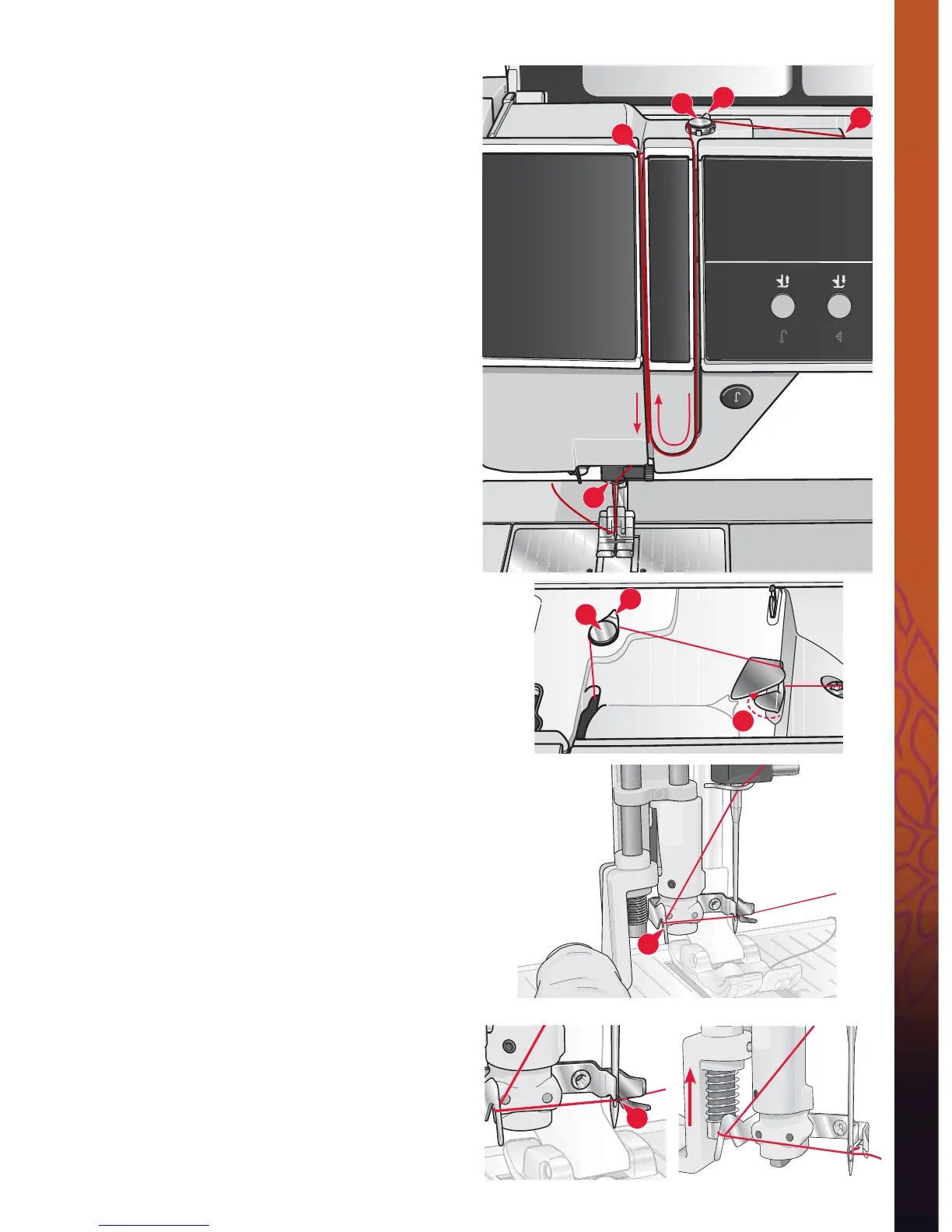

Threading the machine

Make sure that the presser foot is raised and the

needle is in the up position.

1. Place the thread on the spool pin and À t a spool

cap of the right size.

Note: Hold thread with both hands to prevent it from

slacking while threading. This ensures that the thread

will be positioned properly in the threading path.

2. Pull the thread into the thread guide by pulling

it from the front to the back (A). Make sure the

thread clicks into place. Then pull the thread

underneath the bobbin winder thread guide (B)

on the pre-tension disc (C).

3. Thread down through the right-hand threading

slot and then upwards through the left-hand

threading slot.

4. Bring the thread from the right into the take-up

lever (D) and down in the left-hand threading

slot to the needle thread guide (E).

5. Thread the needle.

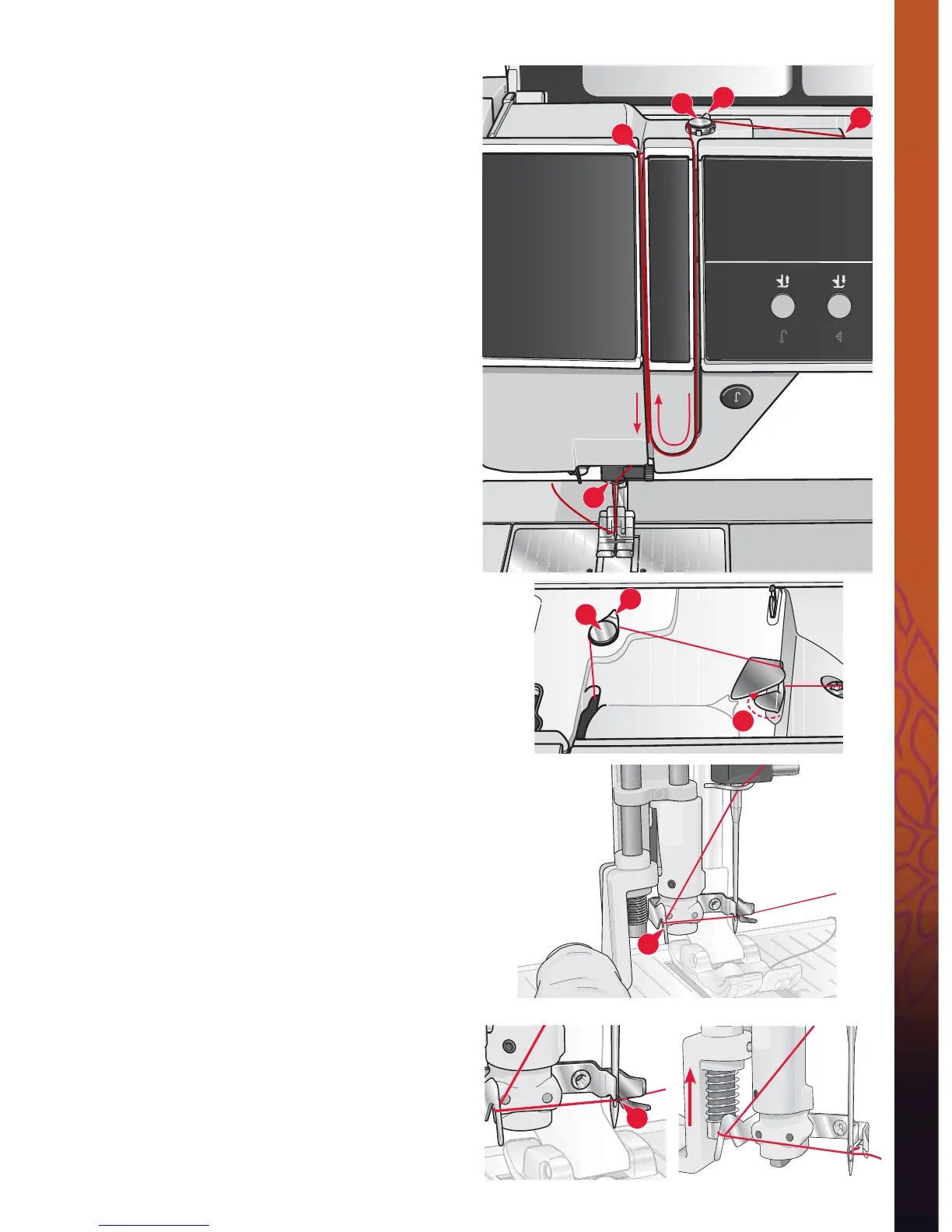

Needle threader

The needle threader allows you to thread the

needle automatically. The needle must be in the up

position to use the built-in needle threader. We also

recommend lowering the presser foot.

1. Use the handle to pull the needle threader all

the way down. The threader hook (G) swivels

through the needle eye.

2. Place the thread from the back over the hook (F)

and under the thread hook (G).

3. Let the needle threader gently swing back. The

hook pulls the thread through the needle eye

and forms a loop behind the needle. Pull the

thread loop out behind the needle.

Note: The needle threader is designed to be used for size

70-120 needles. You cannot use the needle threader for

size 60 needles or smaller, the wing needle, twin needle or

triple needle. There are also some optional accessories that

require manual threading of the needle.

When threading the needle manually make sure that the

needle is threaded from front to back. The bobbin cover

can be used as a magnifying glass.

Loading...

Loading...