4-18 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

4 • Troubleshooting/Diagnostics

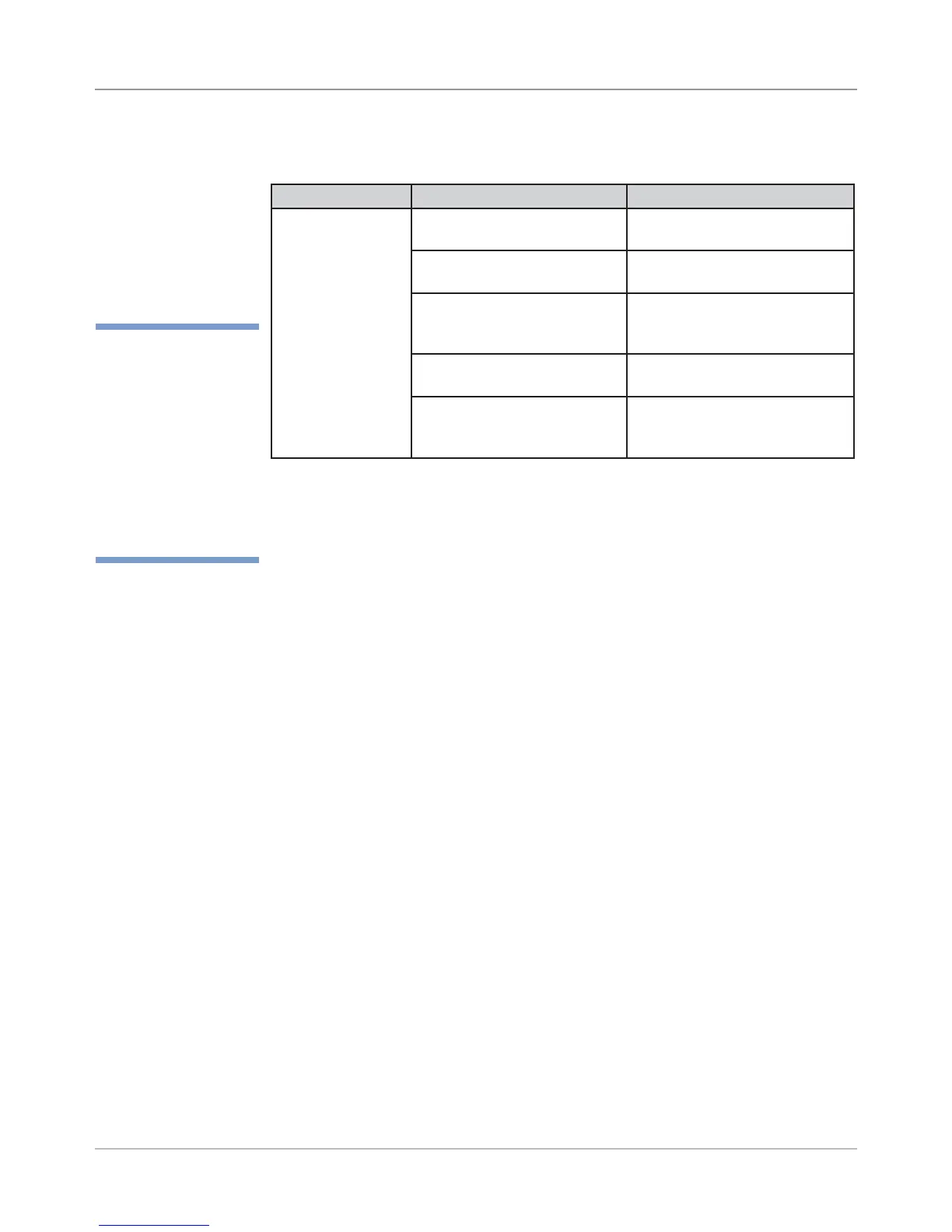

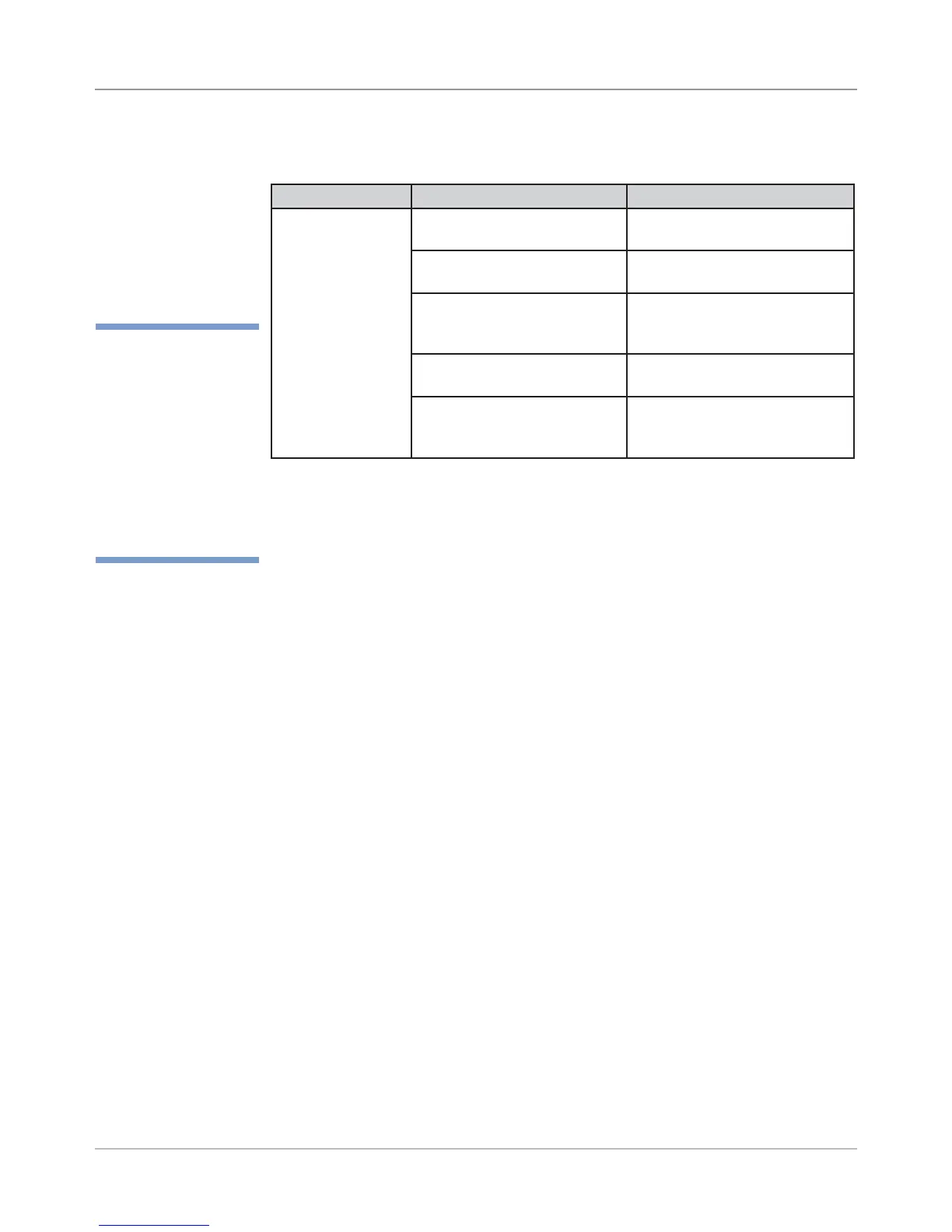

Symptom Possible Cause Solution

Envelope jams,

resulting in Jam

at xxxx” Errors

Media jam Paper path obstructed; clear

jam

Media sticking together Fan media before placing on

feed rollers

Media out of spec Min. thickness 0.003" (0.08 mm)

Max: 0.25" (6.3 mm) (DA80F)

Max: 0.50" (12.7 mm) (DA95F)

“H” Block separators improp-

erly adjusted

Adjust to thickness of material

Faulty or dirty sensor Clean sensors with canned air

or soft cotton cloth, replace if

necessary

4.6 Feeding

Issues

Table 4-8 Feeding Issues

✍

TIP: If you have a

DA95F printer and are

NOT using the stan-

dard feeder (WF9S),

the Feeding Issues

tables on these pages

will NOT apply. Please

refer instead to the

documentation sup-

plied with your feeder.

Loading...

Loading...